Website:

Kaeser Compressors

Website:

Kaeser Compressors

Catalog excerpts

Compressed Air System Guide Provided as a Service by Kaeser Compressors, Inc. Designing Your Compressed Air System How to Determine the System You Need

Open the catalog to page 1

Your compressed air system is a critical plant utility. To function properly and cost effectively, it must be carefully designed to fill the special needs of your applications. Six basic elements—demand, compressed air quality, supply, storage, distribution, and control/management—must be evaluated and factored into final layout considerations to give you optimum results at maximum efficiency. All six elements must work together for the system to reach top performance levels. What Is Your Compressed Air Demand? Determining the true demand in your compressed air system can be difficult but...

Open the catalog to page 2

air systems working at different pressures. Leakage and artificial demand often represent a significant portion of your overall demand. All systems have leaks. Leakage can be measured in several ways while no pneumatic equipment is running: measuring the loaded running time of a compressor, timing the pressure drop of the receiver tank while all compressors are stopped, or measuring leakage at the point of use.Your existing compressed air demand will also include artificial demand caused by excess system pressure that does not increase productivity. Artificial demand can be reduced...

Open the catalog to page 3

4 Visit our Website: www.kaeser.com What Are Your Supply Requirements? Compressed air supply is provided by air compressors.Your compressed air supply, utilizing sufficient storage and proper distribution, must meet your compressed air demand. If supply, storage, and distribution are not in tune, excessive pressure fluctuation will occur, resulting in increased operating cost and reduced productivity. Most compressors are controlled by line pressure. Typically, a drop in pressure signals an increase in demand, which is corrected by increased compressor output. Rising pressure, indicating a...

Open the catalog to page 4

where compressed air is needed. A network of pipelines is used to supply different locations with compressed air. The flow of compressed air in pipelines, however, creates friction and results in pressure drop. Pressure drop in the pipelines should, ideally, be no more than 1 to 2 psi. The following steps can be taken to reduce pressure drop: .. reduce the distance the air must be transported .. reduce the friction through the pipes by increasing pipe size and eliminating unnecessary elbows, valves, and other flow restrictions .. reduce the flow rate of air through the system .. select...

Open the catalog to page 5

6 Visit our Website: www.kaeser.com Optimized Compressed Air System This diagram depicts multiple compressors controlled by a system controller, followed by clean air treatment and a storage air receiver with a flow controller. This setup ensures optimal use of energy. What Are Some Important Layout Considerations? The exact layout of your compressed air system will depend on the interplay of the system elements discussed previously: air demand, air quality, air supply and storage requirements, and distribution considerations. Although information on compressed air generation and use is...

Open the catalog to page 6

What are the Installation Considerations? Compressors, especially medium or large compressors, should be installed in a special compressor room that is clean, dust-free, dry, and cool. If possible, the compressor room should be located in the north side of the building, with all heat-dissipating pipes and machinery being well insulated. To avoid frost and corrosion from condensate accumulation, the temperature in the room should not fall below 40°F. Compressor units should be easily accessible and lighting should be adequate for maintenance and inspections. Because air-cooled compressors...

Open the catalog to page 7

© 2007 Kaeser Compressors, Inc. All rights reserved. 06/07 USGUIDE3 Corporate Headquarters: Kaeser Compressors, Inc. P.O. Box 946 Fredericksburg, VA 22404 (800) 777-7873 Fax: (540) 898-5520 www.kaeser.com Mission Statement We strive to earn our customers’ trust by supplying high quality Kaeser air compressors, related compressed air equipment and premium blower systems. Our products are designed for reliable performance, easy maintenance, and energy efficiency. Prompt and dependable customer service, quality assurance, training, and engineering support contribute to the value our customers...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

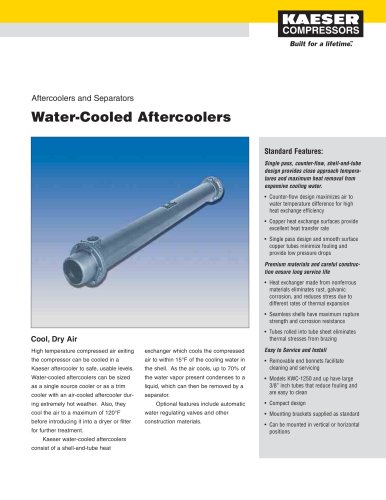

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages