Website:

Kaeser Compressors

Website:

Kaeser Compressors

Catalog excerpts

Dirt, water vapor and other impurities enter the compressor with the atmospheric air. During the compression process, oil (liquid and vapor) is also commonly introduced. If not removed, these contaminants may cause costly production problems such as contamination of equipment, accelerated tool wear and prod- uct rejects. Kaeser offers a complete line of clean air treatment products to prepare compressed air for even the most stringent Selecting Equipment Ambient air temperature, humidity and quality will directly affect the effectiveness of air treatment equipment. Your application and...

Open the catalog to page 2

Global Standards to help facility engineers specify compressed air quality for solid plant, for example, might have a ISO Quality Class |1.2.1 J This is • 0.1 micron particulate filtration Example Air Treatment Configurations with ISO 8573.1 quality classes shown Sand Blasting Paint Spraying Powder Coating High-tech Clean Rooms Chemical Industries (Meets OSHA Grade D) Note 1: All Kaeser Rotary Screw Compressors have built-in aftercoolers. However, for equipment without an aftercooler or where the discharge temperature is 110°F or higher, an aftercooler should be positioned at the location...

Open the catalog to page 3

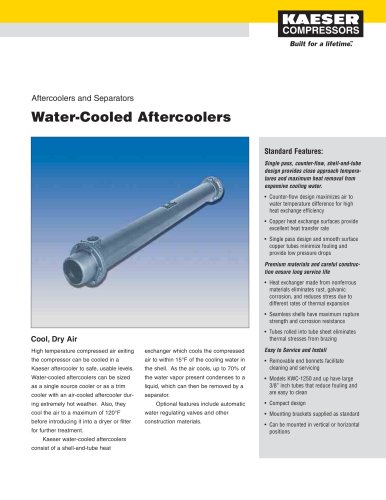

pressor contains water vapor. The compression process heats the air enough that the ingested water vapor is still in the vapor state when air is discharged from the compressor. As the air travels downstream, the vapor cools and condenses into liquid. If not removed, it contaminates the entire compressed air system and causes corrosion. Corrosion in turn leads to air leaks, pressure drops, and scale formation. Products and processes are ruined and lost production time results. to remove water vapor and cool air to safe, usable levels for many applica- tions. Aftercoolers also prepare the air...

Open the catalog to page 4

Condensate Drain Traps Once the moisture is collected it has to be discharged from the system. Kaeser offers a variety of drain traps to remove moisture automatically from separators, receiver tanks, intercool- ers, aftercoolers, dryers, filters, and drip legs. Automatic Magnetic Drain Traps Kaeser's Automatic Magnetic Drain (AMD) and Eco-Drain series of automatic demand drains offer superior energy savings and excellent reliability. Designed only to open when condensate is present, they lower your electrical costs by conserving compressed air for intended uses. The Eco-Drain series is...

Open the catalog to page 5

Filters provide the additional protec- tion from contaminants that degrade process equipment and decrease air tool performance. Filters remove solid particles, oil aerosols, moisture and oil vapors. Adding filters to the compressed air system will save con- siderable costs in process downtime, cleaning tools, and repairing equip- ment. The right filter combination plays a key role in preventing unwanted dirt and oil from reaching end products like food and beverages. Filters up to 780 scfm include bayonetted or screw on housings for easy element replace- ment. Other features include easy to...

Open the catalog to page 6

Single Tower Desiccant Dryer, High Temperature Afterfilter, and High Pressure Oil Mist Eliminators (OME) are simply large oil removal filters with a very low pressure drop. Not only do they remove both oil aerosols and water, but they can handle large slugs of liquid. The cartridge life is normally 8 to 15 years thus requiring virtually no maintenance. Kaeser Activated Carbon Kaeser Activated Carbon Towers (KAT) remove oil vapor and odor. They are used where oil such as food, drugs, and Achemicals. The carbon beds are designed for a long life Single Tower Desiccant Kaeser single tower...

Open the catalog to page 7

Refrigerated dryers serve most com- pressed air applications. Kaeser has a very wide range of refrigerated dryers from 10 to 20,000 scfm for a variety of applications. All Kaeser dryers use environmentally friendly refrigerant. Refrigerated Air Dryer - TX Series Refrigerated Air Dryer - H Series Small Dryers Kaeser offers TX and H series dryers for smaller systems or point of use applications. These hot gas bypass designs combine consistent dew points with simplicity and reliability. Sizes from 10 to 125 scfm Cycling Dryers Kaeser Secotec cycling dryers offer energy savings by using cold...

Open the catalog to page 8

High Pressure Refrigerated Dryers High Capacity Dryers For very large air systems, Kaeser offers high capacity refrigerated dryers in both cycling and non-cycling designs. Up to 10,000 scfm, these open-frame dryers feature plate heat exchangers and separators with hermetic scroll refriger- ant compressors. Above 10,000 scfm, they have super efficient and proven semi-hermetic reciprocating compressors with shell-and-tube heat exchangers. Sizes from 4000 to 20,000 scfm High Pressure Dryers (HT) High pressure applications are also subject to the threat of contaminants and harmful moisture....

Open the catalog to page 9

Desiccant dryers provide extremely dry air for processes that are very mois- ture sensitive or applications where the compressed air system is exposed to very low ambient temperatures. The desiccant material adsorbs moisture in the air until it reaches its maximum capacity at which point it must be regenerated. The method of regeneration is what differentiates the types of desiccant dryers (KAD, KED, Heatless Desiccant Dryer Kaeser Heatless Desiccant Also called "pressure swing" desic- cant dryers, KAD dryers regenerate without an external source of energy. pressed air is used to regenerate...

Open the catalog to page 10

Hybritec Combination Dryer This innovative compressed air drying solution combines the energy savings of a refrigerated dryer with the low dew points of a desiccant dryer. Hybritec units operate on a simple premise: air is first treated by a refriger- ated dryer to remove the majority of the air's water vapor. Then the air is treated by a desiccant dryer to further reduce the dew point. Finally, the air is returned to the refrigerated dryer to be reheated and The advantages of these hybrid dryers over other dryer types include: a consistent outlet dew point, reduced operating and...

Open the catalog to page 11

Condensate Removal mixture of ambient hydrocarbons, compressor lubricant with ambient mois- ture, and particulates that have been concentrated during the compression process. Safely disposing of condensate is a required environmental practice. This oil/water mixture is classified as hazard- ous waste and cannot be discharged into municipal wastewater systems unless Kaeser's Condensate Filters (KCF) offer a reliable and economical method of Kaeser Condensate Filters oil/water separation. Kaeser Condensate Manifold (KCM) The KCM is a small vessel that collects condensate from multiple sources...

Open the catalog to page 12All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages