Website:

Kaeser Compressors

Website:

Kaeser Compressors

Catalog excerpts

Air Compressor Guide Provided as a service by Kaeser Compressors, Inc. Getting the Most for Your Money How to Select and Protect Your Air Compressor Investment Evaluating a Compressed Air System Types of Air Compressors Selecting an Air Compressor Maintenance Troubleshooting Glossary and Reference Data

Open the catalog to page 1

To evaluate a compressed air system, you must begin at the end: What are your air requirements at the point of use? Once you determine exactly what type and how much air you need, you can begin to factor-in design considerations, costs, and efficiencies. Design Considerations Careful planning is essential for smooth operation. System configuration should take into consideration both your requirements and the physical characteristics of your installation. Air-cooled vs. Water-cooled. Aircooled compressors have either integrally-mounted or separate oil and air coolers. These coolers require...

Open the catalog to page 2

Kaeser Air Compressor Guide 7 Troubleshooting In a compressed air system, as in any plant system, problems occur during routine operation. Most of these problems are minor and can be corrected by simple adjustments, cleaning or replacing a part, or eliminating an adverse condition. Any major problem that may develop is generally related to improper cooling or lubrication, poor maintenance and operating practices, or misapplying the system. The troubleshooting chart below is not comprehensive, but indicates some common problems that can develop in compressed air systems using positive...

Open the catalog to page 3

Compressed air is the fourth utility. Along with gas, electricity and water, it is essential to most modern industrial and commercial operations. It runs tools and machinery, provides power for material handling systems, and ensures clean, breathable air in contaminated environments. It is used by virtually every industrial segment from aircraft and automobiles to dairies, fish farming, and textiles. A plant’s expense for its compressed air is often viewed only in terms of the cost of the equipment. Energy costs, however, represent as much as 70% of the total expense in producing compressed...

Open the catalog to page 4

advantages such as flexibility in pressure selection. Automatic belttensioning devices are a must to ensure transmission efficiency and protect bearings from excess stress. Operating Interface: The control panel must be reliable, user-friendly, and run the compressor efficiently. It should indicate operational status as well as offer maintenance interval reminders, diagnostic information and external communications capability for remote monitoring and control. Interconnecting Piping. Look for rigid piping with flexible connections to eliminate leaks. Vibration Isolation. Vibrations can...

Open the catalog to page 5

6 Visit our Website: www.kaeser.com Simple Service Kaeser compressors are designed for easy maintenance and serviceability. The air filter, oil filter, and oil separator are all easy to reach, check, and replace. Special inlet filter mats are readily accessible. To facilitate oil changes, each rotary screw compressor is fitted with an oil change pressurization valve and drain hose. The doors and lid on the compressor cabinet allow immediate access to all maintenance points. Maintenance To most people who select an air compressor, the most important factors are overall cost, efficiency, ease...

Open the catalog to page 6

Kaeser Air Compressor Guide 3 Global Standards ISO 8573.1 was developed in 1991 by ISO (International Organization for Standardization) to help facility engineers specify compressed air quality globally with “Quality Classes” for solid particulates, humidity and oil. Quality classes provide an internationally accepted unit of measure. A typical pharmaceutical plant, for example, would have a compressed air specification of ISO Quality Class 1.2.1. This is equivalent to 0.01 micron particulate filtration, -40° F (-40°C) dew point, and 0.008 ppm (0.01 mg/m3) oil filtration. Quality Classes 0...

Open the catalog to page 7

© 2011 Kaeser Compressors, Inc. All rights reserved. 05/11 USGUIDE1 Corporate Headquarters: Kaeser Compressors, Inc. P.O. Box 946 Fredericksburg, VA 22404 (800) 777-7873 Fax: (540) 898-5520 www.kaeser.com Mission Statement We strive to earn our customers’ trust by supplying high quality Kaeser air compressors, related compressed air equipment and premium blower systems. Our products are designed for reliable performance, easy maintenance, and energy efficiency. Prompt and dependable customer service, quality assurance, training, and engineering support contribute to the value our customers...

Open the catalog to page 8All Kaeser Compressors catalogs and technical brochures

-

Compressed Air Filters

8 Pages

-

Automatic Magnetic Drain

2 Pages

-

Air Treatment Solutions

12 Pages

-

Activated Carbon Tower

2 Pages

-

SmartPipe+TM

28 Pages

-

S Series

8 Pages

-

SX - HSD Series

20 Pages

-

ASD, BSD, and CSD Series

12 Pages

-

KRYOSEC SERIES

4 Pages

-

Portable Compressors

8 Pages

-

Screw Compressor

20 Pages

-

Air Treatment Brochure

12 Pages

-

USGLANCE

6 Pages

-

Mobilair ? M350

2 Pages

-

CLEAN AIR

12 Pages

-

Mobilair M250

2 Pages

-

MobilairM27

2 Pages

-

SigmaControl2

6 Pages

-

Mobilair M122

2 Pages

-

Mobilair M100

2 Pages

-

Mobilair M64

2 Pages

-

Mobilair M57 Utility

2 Pages

-

Mobilair M57

2 Pages

-

Mobilair M50

2 Pages

-

Mobilair M15/M17

2 Pages

-

Mobilair Brochure

6 Pages

-

Hybritec Combination Dryer

8 Pages

Archived catalogs

-

Rotary Screw Vacuum Packages

4 Pages

-

Mobilair Tools

4 Pages

-

Mobilair M270

2 Pages

-

Mobilair M200

2 Pages

-

Mobilair M26

2 Pages

-

Booster Compressors

6 Pages

-

Airbox and Airbox Center

4 Pages

-

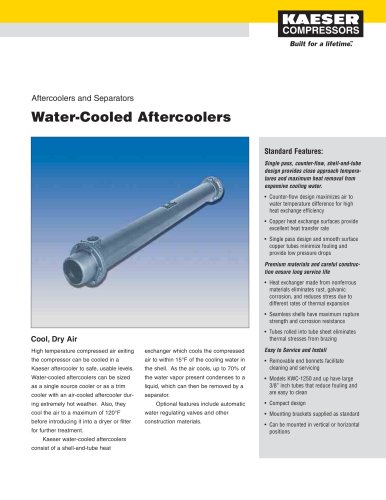

Water-cooled Aftercoolers

2 Pages

-

Air Cooled Aftercoolers

4 Pages

-

Air Main Charging System

4 Pages

-

Condensate Filters

4 Pages

-

Eco-Drain Traps

2 Pages

-

Automatic Magnetic Drain

2 Pages

-

High Temperature Afterfilter

2 Pages

-

Oil Mist Eliminator

2 Pages

-

Compressed Air Filters

8 Pages

-

Activated Carbon Tower

2 Pages

-

Membrane Dryers

2 Pages

-

Breathing Air Systems

4 Pages

-

Desiccant Air Dryers

12 Pages

-

Clean Air Treatment Brochure

4 Pages

-

SmartPipe Modular Piping Catalog

72 Pages

-

SmartPipe Modular Piping

72 Pages

-

HSD Series Compressors

8 Pages

-

ESD and FSD Compressors

6 Pages

-

DSD Series Compressors

6 Pages

-

CSD Series Compressors

6 Pages

-

BSD Series Compressors

6 Pages

-

ASD Series Compressors

6 Pages

-

AS Series Compressors

6 Pages

-

SK Series Compressors

6 Pages

-

SM Series Compressors

6 Pages

-

SX Series Compressors

6 Pages

-

AirCenter

4 Pages