Website:

jbj Techniques Limited

Website:

jbj Techniques Limited

Catalog excerpts

HQ Series VANE PUMPS

Open the catalog to page 1

FIXED DISPLACEMENT HYDRAULIC VANE PUMPS “HQ” SERIES The design of the HQ series vane pumps makes them particularly suitable for application on trucks, especially garbage compactors. All the components subject to wear are contained in a cartridge unit that can be easily removed for inspection and/or replacement without disconnecting the pump from the circuit, drastically reducing expensive machine downtime. The special design of the inner flexible plates of the cartridge enables any thermal expansion in the rotor to be compensated for and to adequately cope with any sudden change in...

Open the catalog to page 2

General description Fixed displacement vane pump, hydraulically balanced, with capacity determined by the type of cartridge used and the speed of rotation. The pump is available in five different displacements from 39 to 66 l/min (from 10 to 17 gpm) at 1000 rpm and 7 bar. Technical characteristics Cartridge model Geometric displacement Maximum pressure Hydraulic fluids: mineral oils, phosphate ester based fluids. Viscosity range (with mineral oil): from 13 to 860 cSt. (13 to 54 cSt. recommended). Filtration: for the inlet - 149 micron abs., for the return line - 25 micron abs. or better...

Open the catalog to page 4

Main operating data max pressure / hydraulic fluid Antiwear industrial Syntetic fire resistant fluid peak pres. (0,5 sec.max) max Speed / hydraulic fluid (with 0 barm the intake pipe) Antiwear industrial Syntetic fire resistant fluid If the intake pressure is not zero bar, use the graph below to find the percentage correction factor to apply to the maximum speed. max speed / intake pipe pressure Intake pipe pressure (BAR)

Open the catalog to page 5

single pump HQ02 Cartridge A02-12 power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W) Temperature: 45°C Inlet pressure: 0 BAR Cartridge A02-14 flow / pressure 725 power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W) Temperature: 45°C Inlet pressure: 0 BAR

Open the catalog to page 6

single pump HQ02 Cartridge A02-17 flow / pressure 725 power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W) Temperature: 45°C Inlet pressure: 0 BAR Cartridge A02-19 flow / pressure 725 power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W) Temperature: 45°C Inlet pressure: 0 BAR

Open the catalog to page 7

flow / pressure power / pressure input torque / pressure Installation dimensions mm (inches) DPTIDNAL OUTLET

Open the catalog to page 8

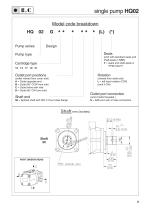

single pump HQ02 Model code breakdown HQ Pump series Design Seals Pump type (omit with standard seals and shaft-seals in NBR) V = seals and shaft-seals in FPM (Viton®) Outlet port positions (outlet viewed from cover end) A = Outlet opposite end B = Outlet 90° CCW from inlet C = Outlet inline with inlet D = Outlet 90° CW from inlet (viewed from shaft end) L = left hand rotation CCW (omit if CW) Outlet port connection Shaft end 50 = Splined shaft with ISO 14 four holes flange (omit if GAS threaded ) S = SAE port with 4 holes connection PORT ORIENTATIONS

Open the catalog to page 9

Shaft seal Parts seals + 2 shaft seals seals + 2 shaft seals Id. codes of pump components

Open the catalog to page 10

General description Fixed displacement vane pump, hydraulically balanced, with capacity determined by the type of cartridge used and the speed of rotation. The pump is available in two different displacements from 75 to 88 l/min (from 20 to 23 gpm) at 1000 rpm and 7 bar. Technical characteristics Cartridge model Geometric displacement Maximum pressure Hydraulic fluids: mineral oils, phosphate ester based fluids. Viscosity range (with mineral oil): from 13 to 860 cSt. (13 to 54 cSt. recommended). Filtration: for the inlet - 149 micron abs., for the return line - 25 micron abs. or better...

Open the catalog to page 11

single pump HQ03 Main operating data max pressure / hydraulic fluid max speed / hydraulic fluid 3625 2900 (with 0 bar in the intake pipe) Antiwear industrial hydraulic oil Syntetic fire resistant fluid Antiwear industrial hydraulic oil Syntetic fire resistant fluid peak pres. (0,5 sec.max) If the intake pressure is not zero bar, use the graph below to find the percentage correction factor to apply to the maximum speed. max speed / intake pipe pressure % connection factor for the max speed Intake pipe pressure (BAR) power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W)...

Open the catalog to page 12

single pump HQ03 Cartridge A03-28 power / pressure input torque / pressure Oil viscosity: 25 c.St. (10W) Temperature: 45°C Inlet pressure: 0 BAR Installation dimensions mm (inches)

Open the catalog to page 13

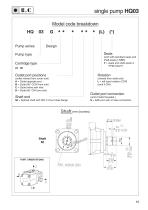

single pump HQ03 Model code breakdown HQ Pump series Design Seals Pump type (omit with standard seals and shaft-seals in NBR) V = seals and shaft-seals in FPM (Viton®) Outlet port positions (outlet viewed from cover end) A = Outlet opposite end B = Outlet 90° CCW from inlet C = Outlet inline with inlet D = Outlet 90° CW from inlet (viewed from shaft end) L = left hand rotation CCW (omit if CW) Outlet port connection Shaft end 50 = Splined shaft with ISO 14 four holes flange (omit if GAS threaded ) S = SAE port with 4 holes connection PORT ORIENTATIONS

Open the catalog to page 14

PART NO. PUMP ROTAT. A0324030 right hand A0328070 A0324040 left hand A0328080 Shaft seal Parts seals + 2 shaft seals seals + 2 shaft seals Id. codes of pump components

Open the catalog to page 15

General description Fixed displacement vane pump, hydraulically balanced, with capacity determined by the type of cartridge used and the speed of rotation. The pump is available in several versions with rated capacities from 46 to 111 l/min (from 12 to 29 gpm) at 1000 rpm and 7 bar. Technical characteristics Cartridge model Geometric displacement Maximum pressure Hydraulic fluids: mineral oils, phosphate ester based fluids. Viscosity range (with mineral oil): from 13 to 860 cSt. (13 to 54 cSt. recommended). Filtration: for the inlet - 149 micron abs., for the return line - 25 micron abs. or...

Open the catalog to page 16

double pump HQ21 Main operating data max pressure / hydraulic fluid max speed / hydraulic fluid 2500 (with 0 bar in the intake pipe) Antiwear industrial hydraulic oil Antiwear industrial hydraulic oil Syntetic fire resistant fluid Syntetic fire resistant fluid cart 12, 14 peak pres. (0,5 sec.max) If the intake pressure is not zero bar, use the graph below to find the percentage correction factor to apply to the maximum speed. max speed / intake pipe pressure % connection factor for the max speed Intake pipe pressure (BAR) power / pressure input torque / pressure Oil viscosity: 25 c.St....

Open the catalog to page 17All Jbj Techniques Limited catalogs and technical brochures

-

PUMP DRIVE COMPONENTS

61 Pages

-

Shaft locking devices

92 Pages

-

HIGH/LOW, 2 STAGE / GEAR PUMPS

14 Pages

-

S-Flex Couplings

32 Pages

-

Hydraulic Gear Motors

56 Pages

-

Planetary Gearboxes

48 Pages

-

Yoke Drive Flywheel Couplings

14 Pages

-

Bearing Supported Stub Shafts

12 Pages

-

This is what we do

1 Pages

-

HQ series vane pumps

48 Pages

-

Pneumatic Starters

6 Pages

-

Coolers & Heat Exchangers

78 Pages

-

Hydraulic power take-off units

28 Pages

-

Gear pump summary

12 Pages

-

FLUID POWER ACCESSORIES

66 Pages

-

F15 Ferra Series

20 Pages

-

KT Pressure Switch

8 Pages

-

Rotary Gear Flow Dividers

16 Pages

-

W Series

8 Pages

-

GPA Series

18 Pages

-

jbj Coolers Summary

2 Pages

-

An excellence in engineering

1 Pages

-

PIPE FLANGES PORT FLANGES

102 Pages

-

TANKS / RESERVOIRS

22 Pages

-

PRESSURE INTENSIFIERS

22 Pages

-

SCREW PUMPS

50 Pages

-

HAZARDOUS AREAS SCREW PUMPS

24 Pages

-

SCREW PUMP RELIEF VALVES

14 Pages

-

BV Series VANE PUMPS

94 Pages

-

BQ Series VANE PUMPS

108 Pages

-

TQ and TV Series VANE PUMPS

36 Pages

-

B1 and B2 Series VANE PUMPS

10 Pages

-

All steel gear couplings

26 Pages

-

This is jbj Techniques!

28 Pages

-

Vane pumps

10 Pages

-

Fluid power accessories

54 Pages

-

Fluid reservoirs

22 Pages

-

pressure intensifiers

22 Pages

-

screw pumps

50 Pages

-

API 676 compliant screw pumps

24 Pages

-

Petrol engine adaptors

6 Pages

-

Torque limiting couplings

20 Pages

-

Torsional couplings

48 Pages

-

jbj PRODUCT SUMMARY

6 Pages

-

Equipment for Hazardous Areas

44 Pages

-

PDC

58 Pages