Website:

Hydratight

Website:

Hydratight

Group: Actuant

Catalog excerpts

It started with one product and a dream. That first product, our NB Clamshell wasto become an industry favorite and ourdream was to become a World Leader inField Machining Equipment. Our productline expands each day and now includesa whole line of patented Clamshells,Boring Bars, End Preps, Portable MillingMachines and much more.As our product line has grown so has ourstature and reputation as a World Leader inField Machining and Heat TreatingEquipment. Were proud of that achieve-ment but definitely not content. Each daywe strive to meet and exceed our cus-tomersҒexpectations with the...

Open the catalog to page 2

T ABLE OF C ONTENT S A ugust 2007 > Clamshellspgs. 1-8Facers & End Prepspgs. 9-11 Grinding & Millingpgs. 12-21 Boring Barspgs. 22-24 Journal Turningpg. 25Hydraulic Power Supplypg. 26Tube Prep pgs 27-28Heat Treatingpgs. 29-30Technical Supportpgs. 31-32Manufacturing & Rental pgs. 33-34 Engineering & Safetypgs. 35-36 Chart & Product Reviewpgs. 37-38 Learn more aboutHydratights Torque andTension tools at: www.hydratight.com >

Open the catalog to page 3

to this small package.The lightweight machine quickly splits and easilymounts on in-line piping systems and the Low Friction Bearing DesignEasily Mounts Super Compact patented strength, accuracy and minimized wear lightweight structure , low friction, bearingdesign. This design adds incorporates our world class, The MC (Mini Clamshell) isdesigned for on-site severing, beveling and counterboring on small piping and valve systems. MCs up to .375Ҕ thick on all alloys > MODEL . The MC willaccommodate all tube sizes ranging from supercompact design > UNIT OFMEASURE MOUNTINGMIN MAX MACHINEID...

Open the catalog to page 4

Std. - in. Metric. - mm 37- 43939.8 - 1092.2 43.51104.9 481219.2 376.2 2.25 57.2 4.5114.3 > * Dimension subject to change with different tooling. Contact your Sales Consultant for specifics.

Open the catalog to page 5

Clamshell Casing Cutte MODELCasing Cutter Unit ofMeasure MountingMin Max MachineID > Std. - inMetric - mm 20 - 26508 - 660.4 26.5673.1 31787.4 376.2 2.25 57.2 4.5114.3 > *Dimension subject to change with different tooling. Contact your Sales Consultant for specifics. r

Open the catalog to page 9

Clamshell Accessories Various configuration of drive motors are available for our NB, MS,and HD Clamshells and BU Facer, including front drives, back drives and angle drives. The power is provided by electric, pneumatic or hydraulic motors depending on your application. > Both of these slides were designed with high speed cutting in mind. High RPM cutting, rapid feed return, cam feed actuation and carbide cutting are just a few of the features that enhance their cutting capability. These modules are perfectly suited for decommissioning work in highly contaminated areas. Flange facing,...

Open the catalog to page 11

Unit ofMeasure ActualSize >

Open the catalog to page 12

Flexible withAdjustable FeedQuick Set-up withMiter MandrelPhonographic FinishNo Tripper Marks Introducing our > GTB2 Machine LengthFacing RangeMin. ClearanceBevel Range Std. - inMetric - mm37939.836.75 - 6.5933.5 -165.127 - 6.5685.8 - 165.124609.6 Generation Two Beveler exacting surface finishes Miter Mandrel for ease of set-up,Internal Rotary Union for better air flow, Pneumatic air oper- ations for less parts and more consistent feed, Ӕ the GTB2.Simple to set-up and operate, this new ID mounted end prep machine delivers no TripperMechanism onvalves, flanges, fittings and more. Features on...

Open the catalog to page 13

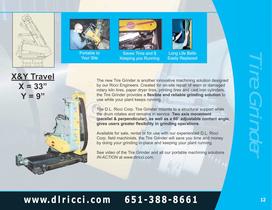

Tire Grinder Portable toYour Site Saves Time and $Keeping you RunningLong Life BeltsEasily ReplacedThe new Tire Grinder is another innovative machining solution designedby our Ricci Engineers. Created for on-site repair of worn or damaged rotary kiln tires, paper dryer tires, printing tires and cast iron cylinders, the Tire Grinder provides a > flexible and reliable grinding solution touse while your plant keeps running.The D.L. Ricci Corp. Tire Grinder mounts to a structural support whilethe drum rotates and remains in service. > Two axis movement(parallel & perpendicular), as well as a...

Open the catalog to page 15

PatentedTechnologyHeavy DutyRigid DesignFast AccuratePortable Grinding Our new Trunnion Grinder provides portable, flexible grindingfor trunnions and other large rollers. This patented technology offers air cylinder controlled tracking rollers. These rollersmay be locked in a forward position to allow the grinding of Trunnion Roll.Resurfacing your trunnions or rolls with the D.L. Ricci Corp.Trunnion Grinder will give them a new finish and .Our operator friendly portable grinding machine is availablefor sale, rental or we can provide on-site technical support. Our experienced Field...

Open the catalog to page 16

Hand Hole Grinder thumb wheelmicro feed adjusts the proper depth-of-cut, Contour FollowingSmooth SurfaceFinishMicro Adjustment so that a minimal amountof material is removed during the grinding process.The grinding power originates from a . The unique roller arrange-ment permits effortless contouring ofout-of-roundӔ hand holes byfollowing the existing shape. Truing the grinder to an existing hole is accomplished by turning the four adjusting screws, and aligning the stone to the adjacent sealing surface. The repairingexisting, worn, abraded and leaking hand hole sealing sur- faces The...

Open the catalog to page 17

Set-up is effortless by virtue of theadjustable mounting fixture and swivel plate. The machine can be accuratelydialed into an existing sealing surface quickly Quick and easy set-up assures a job welldone.Ahigh speed motor with long life heavy duty bearingsand a rugged swing arm design, allows , withminimal material removal required for the re-seating operation. Corroded, pitted, abrad-ed and leaking manway gasket seat surfaces can be restored to like new condition in minutes, using the D.L. Ricci Corp. Oval Manway Seat Grinder. > OvalManwaySeat Grinder Unit ofMeasure accurate cutcontrol >...

Open the catalog to page 18

Portable Milling Machines PortableMill Unit of Measure >

Open the catalog to page 19

Expanding our Milling Capabilities More RigidTool Performance More ToolingVersatility > facing off pitted or mis-aligned surfaces , restoring them to the original condition of the part being machined. smooth and consistent power feed throughoutthe speed range, both in forward and reverse. When used with a facing mill, the T-Mill Machine does a quick job of The T-Mill lineexpands our milling capabilities with Model > Unit ofMeasure Shank Diameter The T-Mill Milling Machine may be smooth, accurate travel inall axes. 4T, 6T and 8T 40 TaperSpindles clamped or bolted directly onto the part being...

Open the catalog to page 20All Hydratight catalogs and technical brochures

-

Portable Boring Bar Brochure

8 Pages

-

Torque Solutions

16 Pages

-

Wind Energy Brochure

8 Pages

-

Subsea Solutions Brochure

12 Pages

-

MORGRIP® Connector Brochure

8 Pages

-

Tensioners Brochure

12 Pages

-

Hydratight Corporate Brochure

26 Pages

-

Ultrasonic Load Monitoring

8 Pages

-

Electric Tensioner Pump

1 Pages

-

Hydraulic Tensioner Pump

1 Pages

-

PowaPak Air Ultra

2 Pages

-

digital turning tool

2 Pages

-

jims

16 Pages

-

Rental Services

4 Pages

-

corporate brochure

28 Pages

-

Hydratight Nuclear Brochure

8 Pages

-

Wind Energy Brochure

8 Pages

-

Subsea Brochure

12 Pages

-

Product and Service Brochure

8 Pages

-

Nutsplitter

1 Pages

-

Drive Motors

1 Pages

-

Hydraulic Power Supply Units

1 Pages

-

Trunnion Grinder

1 Pages

-

Tire Grinder

1 Pages

-

Hand Hole Grinder

1 Pages

-

Oval Manway Seat Grinder

1 Pages

-

XYZ Keyway Cutter

1 Pages

-

Keyway Cutting Machine

1 Pages

-

314 Beveler

1 Pages

-

BU Facer

1 Pages

-

Mini Mill

1 Pages

-

Portable Milling Machine

1 Pages

-

QD Boring Bar

1 Pages

-

Portable Boring Bar

1 Pages

-

Pedestal Valve Boring Bar

1 Pages

-

Axial Feed Module

1 Pages

-

Clamshell Casing Cutters

1 Pages

-

MM180 Clamshell

1 Pages

-

HD Clamshell

1 Pages

-

MS clamshell

1 Pages

-

NB clamshell

1 Pages

-

MC clamshell

1 Pages

-

DL Ricci Clamshell Brochure

7 Pages

-

PowaPak Electric data sheet

2 Pages

-

PowerPak Air Ultra

2 Pages

-

PowaPak Air

2 Pages

-

Torque Brochure

8 Pages

-

Aquajack Tech Data Sheet

1 Pages

-

PS Tensioner

1 Pages

-

HL Tensioner

1 Pages

-

TensionMax

12 Pages

-

QuickFace brochure

2 Pages

-

GTB2 BEVELLER – DATA SHEET

1 Pages

-

LowProfileTBS

1 Pages

-

PortableMilling

1 Pages

Archived catalogs

-

Mini Mill

1 Pages

-

Hand Hole Grinder

1 Pages

-

End Prep Facer

1 Pages

-

BU Facer

1 Pages

-

Axial Feed Module

1 Pages

-

MS Clamshell

1 Pages

-

MC Clamshell

1 Pages