Website:

Howdon Torque limiters

Website:

Howdon Torque limiters

Catalog excerpts

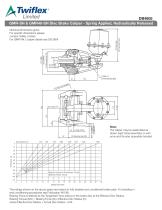

Nominal dimensions given. For specific dimensions please contact Twiflex Limited. For GMR Mk 2 caliper details see DB 3604 305 Fully Worn Pads DB4605 GMR-SH & GMR40-SH Disc Brake Caliper - Spring Applied, Hydraulically Released Brake Disc 3 Holes ø 17 for M16 Mounting Bolts Disc Centre Line Note: The caliper may be assembled as drawn (right hand assembly) or with arms and thruster oppositely handed. 30 40 50 60 70 80 Minimum Pressure for Full Retraction 120 bar Maximum Pressure 150 bar The ratings shown on the above graph are based on fully bedded and conditioned brake pads. For bedding in and conditioning procedures see Publication M1060. Braking Force is defined as the Tangential Force acting on the brake disc at the Effective Disc Radius. Braking Torque (Nm) = Braking Force (N) x Effective Disc Radius (m) where Effective Disc Radius = Actual Disc Radius- 0.06

Open the catalog to page 1

GMR-SH & GMR40-SH Disc Brake Caliper - Spring Applied, Hydraulically Released 76 Fully Retracted 151 Fully Extended Component Part No. Front Cap Rear Cap Push rod Barrel Piston Spring Plate Spring carrier Sleeve Thrust Collar Main Spring Centre Spring Inner Spring Label Stud G 1/4 Plug Wiper Seal 6000242 Component Part No. Bush 1800372 Rod Slip Seal 6000491 Piston Slip Seal 6000492 Bush 1800376 ‘0’-Ring 6000207 Red Cap G 1/4 Redcap G 1/4 Bonded Seal Helicoil lnsert Retraction Screw M8 x 30 Skt. Hd. Screw M16 Nut M8 Spring Washer M16 Spring Washer

Open the catalog to page 2

The GMR-SH and GMR40-SH calipers are available in various ratings, as shown on the performance charts. Part numbers are given below. These are typical performance figures for bedded and conditioned brake pads having a friction coefficient of 0.4. When used with standard Twitlex discs an appropriate ‘service factor’ should be applied when designing the braking system and in the case of brakes used for holding duties or in wet conditions this should be not less than 2.0. Marinised versions are available to special order. A monitoring unit is also available (Part No. 7700212) which is fitted...

Open the catalog to page 3

GMR-SH & GMR40-SH Disc Brake Caliper - Spring Applied, Hydraulically Released the pushrod are engaged in the slot in the caliper arm. (A 17mm A/F spanner will fit the flats on the push rod). N.B. Keep fingers clear of the space between push rod and caliper arm at all times. If an inclined mounting kit is fitted, the stop screw should be re-adjusted to maintain equal pad clearance on either side of the disc. 2.5 Pad wear can be monitored by observing the gap between the lugs on the pads pressure plates and the machined surfaces on the caliper frame, when the brake is applied. Pads must be...

Open the catalog to page 4

GMR-SH & GMR40-SH Disc Brake Caliper - Spring Applied, Hydraulically Released be extracted from the front cap by application of low fluid pressure to the inlet port. The piston and rod seals each have two parts, (a P.T.F.E. sealing ring and an 0-ring) which may be extracted using a small screwdriver or similar tool, taking care not to damage the grooves. Once removed the seal should not be re-used. When fitting a new rod seal (after fitting the 0-ring) the P.T.F.E. ring must be carefully collapsed into a kidney shape (avoid sharp bends), inserted into the internal groove and then expanded...

Open the catalog to page 5

Oil PressureOilbar Oil Pressure - bar - Pressure - bar Minimum Pressure for Full Retraction 100 bar Maximum Pressure 130 bar Minimum Pressure for Full Retraction 100 bar Maximum Pressure 130 bar 6 Oil PressureOilbar Oil Pressure - bar - Pressure - bar Minimum Pressure for Full Retraction 85 bar Maximum Pressure 130 bar Minimum Pressure for Full Retraction 85 bar Maximum Pressure 130 bar Minimum Pressure for Full Retraction 85 bar Maximum Pressure 130 bar 10 12 14 16 18 Braking Torque kNm Disc Diameter mm Oil PressureOilbar Oil Pressure - bar - Pressure - bar Minimum Pressure for Full...

Open the catalog to page 6All Howdon Torque limiters catalogs and technical brochures

-

BSAB 90 DUAL-action

2 Pages

-

superior braking solutions

10 Pages

-

superior solutions

8 Pages

-

hydraulic-power-units

22 Pages

-

SOBO® iQ

1 Pages

-

Svendborg Brakes

112 Pages

-

Layrub Couplings

2 Pages

-

Industrial Disc Brakes

48 Pages

-

DB 2002

2 Pages

-

DB 2009

2 Pages

-

DS2508

2 Pages

-

DS2000 MR Disc Brake Caliper

2 Pages

-

DS1500 MS Disc Brake Caliper

2 Pages

-

DS1000 MU Disc Brake Caliper

2 Pages

-

Brake Disc Hubs

1 Pages

-

Brake Discs

1 Pages

-

Torque Limiter Brochure

8 Pages

-

Wedgegard® Phasing Hub

1 Pages

-

Wedgegard® NFS Coupling (Nm)

1 Pages

-

Wedgegard® DFS Coupling (Nm)

1 Pages

-

Wedgegard® PFS Coupling (Nm)

1 Pages

-

Wedgegard® CFS Coupling (Nm)

1 Pages

-

Chain Type Coupling

1 Pages

-

Gear Type Coupling

1 Pages

-

PFS Coupling

1 Pages

-

DFS Coupling

1 Pages

-

NFS Coupling

1 Pages

-

Type S HUB

1 Pages

-

Type SAE Spacer

1 Pages

-

Disc Hubs

1 Pages

-

Phasing Hubs

1 Pages

-

DS1508

2 Pages

-

DS1507

2 Pages

-

DS1003

2 Pages

-

Type CFS Coupling

1 Pages

-

Chain & Pulley Drives

1 Pages

-

Type DIN Spacer

1 Pages