Website:

HORIBA STEC

Website:

HORIBA STEC

Group: Horiba

Catalog excerpts

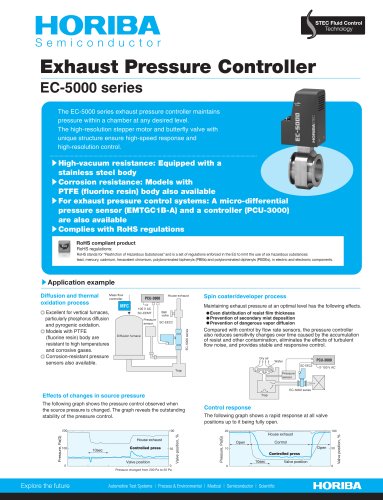

Exhaust Pressure Controller EC-5000 series The EC-5000 series exhaust pressure controller maintains pressure within a chamber at any desired level. The high-resolution stepper motor and butterfly valve with unique structure ensure high-speed response and high-resolution control. sHigh-vacuum resistance: Equipped with a stainless steel body sCorrosion resistance: Models with PTFE (fluorine resin) body also available sFor exhaust pressure control systems: A micro-differential pressure sensor (EMTGC1B-A) and a controller (PCU-3000) are also available sComplies with RoHS regulations RoHS compliant product RoHS regulations: RoHS stands for “Restriction of Hazardous Substances” and is a set of regulations enforced in the EU to limit the use of six hazardous substances: lead, mercury, cadmium, hexavalent chromium, polybrominated biphenyls (PBBs) and polybrominated diphenyls (PBDEs), in electric and electronic components. sApplication example Mass flow controller Excellent for vertical furnaces, particularly phosphorus diffusion and pyrogenic oxidation. Models with PTFE (fluorine resin) body are resistant to high temperatures and corrosive gases. Corrosion-resistant pressure sensors also available. House exhaust Pressure sensor Spin coater/developer process Maintaining exhaust pressure at an optimal level has the following effects. thickness •Even distribution of resist filmdeposition •Prevention of secondary mist diffusion •Prevention of dangerous vapor Ball valve SC-EEC2 EC-5000 series Diffusion and thermal oxidation process Diffusion furnace Compared with control by flow rate sensors, the pressure controller also reduces sensitivity changes over time caused by the accumulation of resist and other contamination, eliminates the effects of turbulent flow noise, and provides stable and responsive control. Dry air Pressure sensor Effects of changes in source pressure Controlled press Valve position 0 Pressure changed from 200 Pa to 50 Pa The following graph shows a rapid response at all valve positions up to it being fully open. Valve position, % Control response House exhaust Control Valve position, % The following graph shows the pressure control observed when the source pressure is changed. The graph reveals the outstanding stability of the pressure control.

Open the catalog to page 1

Corrosion-resistant pressure sensor ► External dimensions (unit RoHS compliant •Model with corrosion-resistant plastic (PEEK) 0 The contents of this catarog are subject to change without prior notice, and without any subsequent liability to this company. 0 It is strictly forbidden to copy the content of this catalog in part or in full. 0 All brand names, product names and service names, in this catalog are trademarks or registered trademarks of their respective companies. HEAD OFFICE 11-5, Hokodate-cho, Kamitoba, Minami-ku, Kyoto, 601-8116 Japan HORIBA STEC Co., Ltd TAIWAN Branch 3R, No.18,...

Open the catalog to page 2All HORIBA STEC catalogs and technical brochures

-

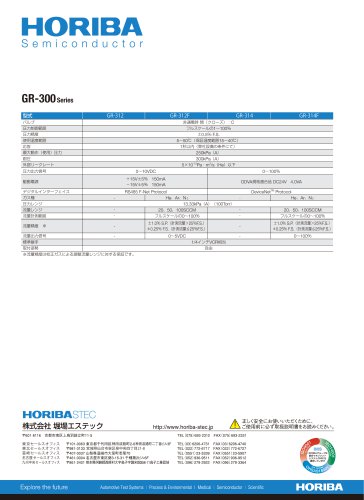

GR-300 Series

1 Pages

-

1000M Series

2 Pages

-

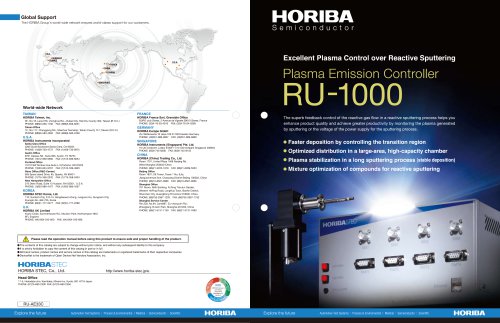

ru1000

4 Pages

-

HF HD-960L

5 Pages

-

CVS-ONE Brochure

4 Pages

-

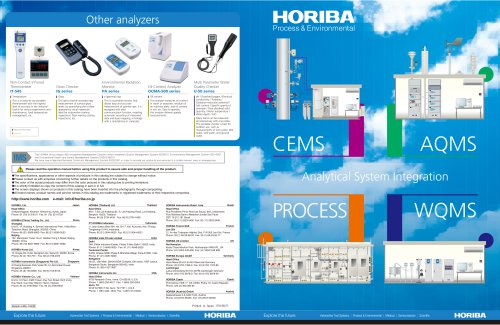

CEMS

4 Pages

-

Cathodoluminescence H-CLUE

5 Pages

-

Cathodoluminescence F-CLUE

5 Pages

-

HE-960HC

5 Pages

-

CAMSIZER X2 Brochure

12 Pages

-

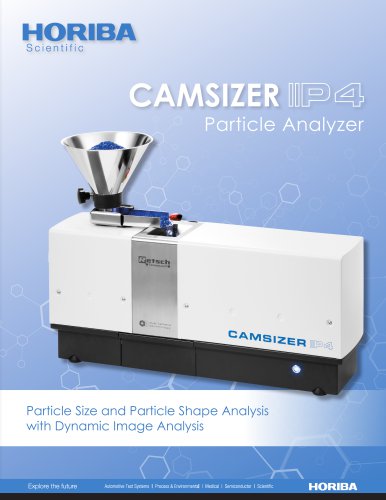

CAMSIZER P4 Brochure

12 Pages

-

Brochure-TPNA-500

6 Pages

-

AP-370 Series Brochure

12 Pages

-

OMNI TERS Probes

2 Pages

-

NanoRaman Brochure

7 Pages

-

51 series Brochure

6 Pages

-

VULCAN Evo

4 Pages

-

MEDAS

8 Pages

-

OBS-ONE GS

6 Pages

-

MEXA-ONE Brochure

26 Pages

-

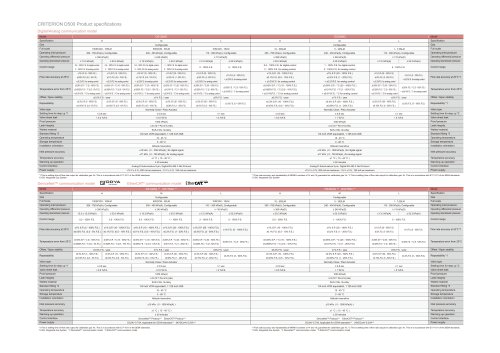

CRITERION D507 Series

3 Pages

-

Mass flow Controller & Meter

2 Pages

-

Oil analysis

3 Pages

-

Back number of CSR Reports

13 Pages

-

HORIBA Report

86 Pages

-

Soap Film Flow Meter

1 Pages

-

Analog pressure regulator

1 Pages

-

MI/MV

1 Pages

-

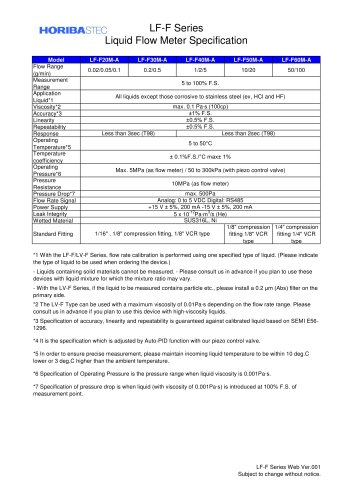

LV-F series

1 Pages

-

LF-F series

1 Pages

-

Criterion, D200 series

16 Pages

-

Pressure Controller

8 Pages

-

SEC-Z500MGX

16 Pages

-

Fluid Controle Equipment

4 Pages

-

Rasidual Gas Analizer

6 Pages

-

Vaporizers

8 Pages