Catalog excerpts

SL2 stainless steel based slide system

Open the catalog to page 1

For amendments and updates visit www.HepcoMotion.com and select literature button. Introduction System Composition Stainless Steel Based Slide System Based on the proven Generation II range, Hepco’s SL2 System offers the user basic interchangeability with Gen II and GV3 components in Application Examples Assemblies, Flat Slides and Spacer Slides. A complementary range of lightweight aluminium Carriage Plates and Flange Clamps is Data and Dimensions Assembled Systems an extensive linear range consisting of stainless steel Bearing also available, with special surface 6-9 treatment providing...

Open the catalog to page 2

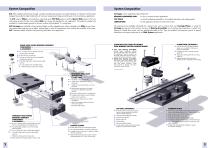

System Composition System Composition SL2 offers excellent performance through a quality manufacturing process and careful selection of materials, and has been designed to provide the ideal combination of corrosion resistance and long service life even in the most arduous application. Carriages can be supplied by Hepco fitted with: BEARING ASSEMBLIES ONLY - for dry or minimum friction applications. The SL2 range of Slides is very extensive, comprising seven Flat Slide sections and four Spacer Slide sections. This very wide range ensures that the most suitable Slide can always be specified...

Open the catalog to page 3

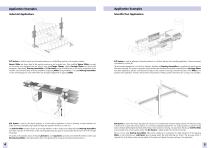

Application Examples Application Examples Industrial Applications Scientific/Test Applications SL2 System is used for vertical and horizontal guidance on a bottle filling machine in the cosmetics industry. SL2 System is used for telescopic horizontal guidance in a Nuclear Industry drum handling application. Vertical movement is provided by a scissor lift. Spacer Slides are shown fixed to the machine structure on the horizontal axis. Short undrilled Spacer Slides are used on the vertical axis supported one end only by long type Flange Clamps. Hepco Carriage Plates are shown used throughout....

Open the catalog to page 4

Assembled Systems Assembled Systems SL2 can be ordered as individual components or as a Factory Assembled System. Ready-assembled Carriages are available with just the Bearing Assemblies fitted, or with the addition of either Cap Seals or Lubricators. Assembled carriages can also be ordered in a controlled height version (CHK) which minimises variation in the AA dimension*5. This is desirable in high precision applications. (see Stock SL2 Carriage table page 9). The following three pages show important reference dimensions between assembled components, as well as the maximum overall sizes...

Open the catalog to page 5

Assembled Systems Assembled Systems Blind Hole Fixing Bearing Assemblies are for use where access to the back of the mounting plate is not possible or where the thickness of the mounting plate prevents use of the Through Hole Fixing Bearing Assemblies. These circumstances are not relevant to the use of Hepco Carriage Plates, therefore systems using Blind Hole Fixing Bearing Assemblies are not available factory assembled. Ordering Assembled Systems Once the component combination for an assembled system has been decided upon, the table below can be consulted for availability and a part number...

Open the catalog to page 6

Stainless Steel Spacer and Flat Slides Stainless Steel Spacer and Flat Slides Hepco SL2 stainless steel Slides are zone hardened on the ‘V’ edges and precision ground on all main surfaces to a high degree of parallelism. Slide fixing holes are accurately positioned, allowing Customers to pre-drill their mounting holes. All Hepco Slides are left ‘soft’ in the centre portion for subsequent machining if required. However, since SL2 Slides are specially finished to promote resistance to corrosion, Customers should be aware that machining may reduce localised corrosion resistance. To maximise...

Open the catalog to page 7

Stainless Steel Bearing Assemblies Stainless Steel Bearing Assemblies A number of Bearing Assembly options are available from Hepco in order to cater for most design requirements. The Through Hole Fixing type is available in two stud lengths covering most thicknesses of carriage or mounting plate, the short stud version being compatible with the Hepco Carriage Plates. The Twin Bearing type comprises two individual deep groove ball bearings on a single stud. This construction offers some compliance, which allows smoother running and is more tolerant of misalignment or uneven mounting...

Open the catalog to page 8

Aluminium Carriage Plates Aluminium Carriage Plates Hepco lightweight aluminium Carriage Plates are finished with a proprietary U.S. Dept. of Agriculture approved corrosion resistant coating. For convenience and reliability it is recommended that customers specify complete factory assembled systems (see page 9). Individual Carriage Plates are available for customers who prefer to carry out their own assembly. There is a range of three useful lengths in each size, available in two different types according to whether or not the Carriage Plate length will accommodate Cap Seals and Lubricators...

Open the catalog to page 9

Aluminium Flange Clamps Flange Clamps enable the Slide System to act as a self-supporting constructional element of the machine. Manufactured from aluminium alloy, the clamps are then treated with a corrosion resistant coating certified by the U.S. Department of Agriculture. They are available for use with SS NS25, SS NM44, and SS NL76 section Spacer Slides only. Short Flange Clamps (type SFC) enable the Slide to be supported between two opposing faces. The Long Flange Clamp (type LFC) enables short lengths of Slide to be supported from one end only. The machined base mounting facility may...

Open the catalog to page 10

Technical Data Load/Life Calculations Maximum moment and direct load capacities for the SL2 System are given in the table below. Capacities are given for ‘dry’ and ‘lubricated’ conditions - this refers to the ‘V’ contact, since all Bearing Assemblies are greased for life internally. Values are based on shock-free duty. Load/Life Calculation Examples Carriage Dry System, Twin & DR Type Bearing Lubricated System, Twin Type Bearing Lubricated System, DR Type Bearing Type L1(max) L2(max) Ms(max) Mv(max) M(max) L1(max) L2(max) Ms(max) Mv(max) M(max) L1(max) L2(max) Ms(max) Mv(max) M(max)...

Open the catalog to page 11All HepcoMotion catalogs and technical brochures

-

HLG Hepco Linear Ball Guides

17 Pages

-

SBD Sealed Belt Drive

11 Pages

-

MFS machine fencing system

6 Pages

-

HGS gantry solutions

9 Pages

-

HDS2 Heavy Duty Slide System

27 Pages

-

DTS2 Dynamic Track Systems

8 Pages

-

PRT2 No. 2 Installation Details

10 Pages

-

PRT2 No.8 DTS Components

19 Pages

-

PRT2 No. 11 Mix & Match

3 Pages

-

PRT2 1-Trak

8 Pages

-

Floating Bearings

2 Pages

-

DualVee Wash Down Wheels

2 Pages

-

MCS Catalogue

36 Pages

-

Profiles with Linear Guides

8 Pages

-

ALR Aluminium Rings

4 Pages

-

HTS Drawer Slides Catalogue

40 Pages

-

MHD Catalogue

8 Pages

-

PSD80 No.1 Ballscrew

6 Pages

-

HDRT Heavy Duty Ring and Tracks

13 Pages

-

Uni-Guide – Product Overview

4 Pages

-

ZIMM GSZ & Z Series Screw Jacks

196 Pages

Archived catalogs

-

BSP Ballscrew Premier

9 Pages

-

PRT2 No.6 Bleed Lubrication

8 Pages

-

DualVee Technical Data Guide

12 Pages

-

DualVee Guide Wheels Catalogue

11 Pages

-

MCS – RapiLok

2 Pages

-

ZIMM – Z Series Leaflet

4 Pages