Website:

GRUNDFOS

Website:

GRUNDFOS

Group: Grundfos

Catalog excerpts

GRUNDFOS SP ENGINEERING MANUAL

Open the catalog to page 1

Contents 1 Introduction 2 Water supply Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Groundwater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Groundwater wells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Riverbank filtration ....

Open the catalog to page 3

Introduction Serving our common interests This engineering manual has been created with a specific focus on one of Grundfos’ most recognisable and popular pumps: the SP. When it was created in the late 1960’s, this breakthrough product set new standards within durability, efficiency, and construction in thin-plate stainless steel. The numerous product types, sizes, and configuration possibilities available today serve as a testament to the innovative nature of the original SP pumps. Working with SP pumps on a daily basis often gives rise to lots of different questions. We have created this...

Open the catalog to page 4

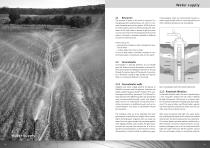

Water supply The amount of water in the world is constant. It is changing position, quality, phase, etc., but it is constant. Seawater accounts for approx. 97.5% of all water. Fresh water accounts for the remaining 2.5%. Two- thirds of the fresh water is bound as glaciers, polar ice, and snow cover. The remaining, less than 1% of all water in the world, is somehow available in different sources for mankind to use. These sources are: • groundwater, shallow or deep underground aquifers of water • surface water, from rivers or lakes. In case no fresh water is available, seawater or...

Open the catalog to page 5

Water supply feeding the riverbank wells when the river water level runs low in dry season. The storage of river water in aquifers causes less water stress on the river during dry seasons. Riverbank wells can be constructed like groundwater wells, or from 7-8m vertical casings dug down under the riverbed. They can be supplemented with 8-12 horizontal injected steel screens or filters for sediment-free water intake. Water supply To find the peak hourly consumption, please refer to the MPC-Booster section of Grundfos WinCAPS/WebCAPS or figures 4 and 5. Pump-out requirement Water is used by...

Open the catalog to page 6

Water supply Water supply An increase from 10 to 20 m3/h will consequently result in a lowering of the water level of approx. 1 m. An increase from 10 to 30 m3/h will give a lowering of the water level of approx. 2m. Clean-water tank size as a percentage of daily consumption % 100 90 Clean-water tank size as a percentage of daily consumption: Tank volume (m3) x 100 = % tank capacity Daily consumption (m3/24h) If the well yield is not sufficient to meet the water requirement, even by prolonged operation, the following should be done: • Have a specialist look at the problem. • Have a...

Open the catalog to page 7

Water supply Surface water 2.3.1 From freshwater sources Surface water is usually taken from lakes or rivers. Unlike groundwater, it is not protected from nature or human activities, and treatment is therefore always necessary. Surface water level and quality will vary over the seasons. For example, after heavy rainfall, or snow melt, lots of solids and sand are washed downstream. These sharp and abrassive minerals as well as biodegradable materials are to be settled or screened off before pump intake to avoid negative effects on the final water treatment process. Submersible pumps are...

Open the catalog to page 8

The supply of fresh water for drinking water, irrigation and various industrial applications is the most common application for submersible pumps. Pumps of many different designs, and made from many different materials can be used with a reasonably good result here. Grundfos SP pumps made of stainless steel EN 1.4301/ AISI 304 are the obvious choice for this application. If the well is made correctly and produces clean, sandfree water, the pump can last for many years. However, in some livestock watering and irrigation applications, the water quality is so poor that pumps made of standard...

Open the catalog to page 9

4. rop directly down (90°).The aggressive CO2 conD tent has increased the material loss to 0.25mm. Note the salinity level of the water (point 4). Draw a horizontal line through this point; follow it to the left and read the results. 5. ecommended service intervals for your pump: AfR ter every 6,000 hours of operation (point 5). 6. oss of efficiency: Approx. 18% (point 6). L 7. stimated cost of renovating the pump: 75% of the E price of a new pump (point 7). to the submersible pump, and high-grade stainless steel is recommendable. A special mining application is leach mining, where an...

Open the catalog to page 10

Pumping water from a tank or reservoir is very often done with a standard submersible pump. A submersible pump has many advantages compared to a dry-installed pump such as: • ow noise level: The submersible pump is very siL lent and does not disturb any neighbours. • heft proof: The pump is installed at the bottom of T the tank/reservoir. • o shaft seal: This eliminates the risk of leakage N above ground. In horizontal installations, Grundfos always recommends that you include a flow sleeve and baffle plate at low water levels. If more than one submersible pump is installed in a tank or...

Open the catalog to page 11

Submersible pumps are used for many seawater applications like fish farming, offshore industrial applications and water supply for reverse osmosis-treated water. SP pumps are available in different materials and corrosion classes depending on the application of the pumps. The combination of salinity and temperature is not favourable to stainless steel, and must always be taken into consideration. A good way to compare the corrosion resistance of stainless steel, is to compare its resistance against pitting. The figure used as a comparison is called: ‘Pitting Resistance Equivalent’ (PRE)....

Open the catalog to page 12All GRUNDFOS catalogs and technical brochures

-

GRUNDFOS PUMPS FOR MINING

5 Pages

-

GF 270, Solar modules

2 Pages

-

A WIDE RANGE

60 Pages

-

GRUNDFOS ALPHA2

20 Pages

-

Grundfos ALPHA1

24 Pages

-

Grundfosliterature-145421

21 Pages

-

Grundfosliterature-145418

3 Pages

-

Grundfosliterature-6119761

59 Pages

-

Grundfosliterature-4352972

3 Pages

-

Grundfosliterature-3081300

5 Pages

-

ALPHA1 L

2 Pages

-

DME

2 Pages

-

GRUNDFOS CR 95 - CR 155

2 Pages

-

UPM3

92 Pages

-

GRUNDFOS UPM3

11 Pages

-

Vaccuperm VGA and VGB

28 Pages

-

PURIFY YOUR BUSINESS

9 Pages

-

PUST 1700 RANGE

3 Pages

-

GRUNDFOS WASTEWATER PRODUCTS

10 Pages

-

Grundfos LiqTec

2 Pages

-

CRN high pressure programme

2 Pages

-

ATEX approved CR pumps

2 Pages

-

CRN Air-Cooled Top

2 Pages

-

CRN MAGdrive

2 Pages

-

GRUNDFOS CRE

2 Pages

-

Customised solutions

21 Pages

-

TPE3

7 Pages

-

Grundfosliterature

5 Pages

-

CIM/CIU

3 Pages

-

BMS

5 Pages

-

BM

2 Pages

-

BACMON

16 Pages

-

AQtap

7 Pages

-

ALPHA2 L OEM

19 Pages

-

A WIDE RANGE

60 Pages

-

SEG Autoadapt and GRM

2 Pages

-

E-Solutions and GRM

2 Pages

-

Grundfos Remote Management

3 Pages

-

CRE GRUNDFOS

2 Pages

-

MTA

3 Pages

-

Unilift CC

2 Pages

-

HS Horizontal Split Case

4 Pages

-

DMH-API - Product leaflet

2 Pages

-

DMH -Product leaflet

2 Pages

-

ALPHA1

2 Pages

-

BMEX Booster Seawater

2 Pages

-

AMD-AMG-AFG

3 Pages

-

S - product brochure

16 Pages

-

Customised pump solutions

12 Pages

-

CRT for seawater

2 Pages

-

CRT for industry

2 Pages

-

CRT - for desalination

2 Pages

-

HS

5 Pages

-

SQ

3 Pages

-

MAGNA/UPE

12 Pages

-

Pressure Manager

5 Pages

-

Selcoperm SES

20 Pages

-

Conex DIA-1, DIA-2, DIA-2Q

2 Pages

-

Conex DIS-G

2 Pages

-

Conex DIS-C

2 Pages

-

Sololift2

9 Pages

-

VGA and VGB

28 Pages

-

Oxiperm Pro

8 Pages

-

DMX

18 Pages

-

DMH

18 Pages

-

MP 204

3 Pages

-

TP/TPE

5 Pages

-

TP,TPE - product brochure

5 Pages

-

SP Product

7 Pages

-

SMART Digital dosing pumps

2 Pages

-

GRUNDFOS SE & SL ranges

8 Pages

-

S-Tube

4 Pages

-

SB & SBA

8 Pages

-

HOME AND GARDEN

52 Pages

-

Product Brochure

5 Pages

-

Multilift

21 Pages

-

NB, NBG, NK, NKG

3 Pages

-

MAGNA3 - MORE THAN A PUMP

7 Pages

-

KPL and KWM

3 Pages

-

GRUNDFOS BOOSTER (Hydro MPC)

3 Pages

-

Grundfos GO

3 Pages

-

DW

12 Pages

-

DIP

16 Pages

-

GF100 TF solar module

2 Pages

-

GRUNDFOS CONTROL MPC

5 Pages

-

E-solution with Grundfos E-pumps

16 Pages

-

Sanitary Assembly Tool Kit

2 Pages

-

Durietta - Product brochure

3 Pages

-

Food application pumps

7 Pages

-

CM ? product brochure

7 Pages

-

SQFlex ? product brochure

7 Pages

-

SRP ? product brochure

3 Pages

-

NEW ALPHA2

7 Pages

-

Wastewater products

10 Pages

-

GRUNDFOS DWK

3 Pages

-

GRUNDFOS DPK range

3 Pages

-

GRUNDFOS DP

5 Pages

-

DIT-L, DIT-M Photometer

16 Pages

-

DME, DMS, DDI

14 Pages

-

Diffuser

3 Pages

-

CUE E-SOLUTIONS

12 Pages

-

CR monitor

8 Pages

-

CR ? Innovation inside

20 Pages

-

Control MPC

4 Pages

-

CMV

8 Pages

-

CM, CME Booster

52 Pages

-

CIM / CIU

3 Pages

-

BMP

9 Pages

-

Electro Magnetic Technology

52 Pages

Archived catalogs

-

A Wide Range of Quality Products

32 Pages

-

Grundfos CR - Custom-built Pumps

15 Pages