Website:

GEFA Processtechnik

Website:

GEFA Processtechnik

Catalog excerpts

G M B H Valve Technology Catalogue P R O C E S S T E C H N I K

Open the catalog to page 1

»GEFA Processtechnik – The name that stands for quality & innovation.« 4

Open the catalog to page 4

T e c h n o l o g y V a l v e s Our product ranges ■ Valves & Controls • Shut-off and Control valves • Ball valves • Knife Gates valves • Non Return valves • Actuators • Speciality valves i n ■ Measurement and Control Technology • Flow rate measurements • Signal processing modules C o m p e t e n c e • Custom control cabinets and panels G E F A – • Pressure transmitters • Temperature measurements 5

Open the catalog to page 5

Centrally mounted Solid one-piece valve disc and stem. Extremely easy to service: Quick seat ring changeout possible with two-piece body VDI 2440 EPDM Body completely elastomer-lined with seat ring as multifunctional sealing element Operational for almost all media from acid application to sensitive food or pharmaceuticals Control and regulation of process sequences without hysteresis 6 Process valve Advantages Series K KG 9 · KG 7 · K 19 · K 17 · K 08 · K 07 · K 11 S o f t - s e a t e d B u t t e r f l y va l v e S e r i e s K The Types Type KG 9 [ DN 50 - DN 300 ] Technical Data: Wafer...

Open the catalog to page 6

Safe and secure automation with the interchangeable top flange G E FA - M U LT I T O P Two-piece body Standard construction length; easy to service, simple replacement of the internal parts to the two-piece body construction ts Qu en a 2 equire m y r lit PED 97 / 23 / EC trol Perm AD 2000 on AD - WO a nt qu alit y c 3 Bearing bushing with O-ring seal 4 ne Primary seal Integrated in the seat ring, causes space-free and pressure-stable sealing to the outside, additional labyrinth design 5 4 5 6 2 6 Seat ring Multifunctional sealing element, single-piece replacement, maintenance-free, long...

Open the catalog to page 7

S o f t - s e a t e d B u t t e r f l y va l v e S e r i e s K Type K 19 [ DN 350 - DN 500 ] Type K 08 [ DN 600 - DN 1200 ] Type K 11 [ DN 25 – DN 150 ] Technical Data: Wafer type butterfly valve for installation between flanges DIN EN 1092-1, PN 10/16, ANSI 150, Two-piece body, self-centring, One-piece valve disc and stem, leak-proof to 16 bar, vacuum-tight. Face to face dimensions: DIN EN 558-1 series 20 (DIN 3202-K1) Top flange: ISO 5211 Test: : EN12266-1, P10/P11/P12-A DIN 3230, T3 - BA/BO-1, DIN 3230, T5, T6 Technical Data: Wafer type butterfly valve for installation between flanges...

Open the catalog to page 8

Technical Data Control range: 20° - 60° Opening angle Pressure/Temperature Diagram 16 Seat ring replacement 15 14 13 MVQ v a l v e s 11 10 FPM 1 7 PU After loosening the two body bolts, only the lower part of the body is pulled out along with the inner parts. The actuator remains mounted to the top of the body! 6 NBR 5 EPDM CSM 4 3 2 1 0 0 50 100 150 200 Temperature °C As of DN 200, at a differential pressure above 13 bar, seat rings with an increased shore hardness are required. Vacuum tight to 1 x 10-2 mbar KG7 / K17 / K14: In single-side flange status max. differential pressure 10 bar...

Open the catalog to page 9

S o f t - s e a t e d B u t t e r f l y va l v e Ty p e K G 2 · K G 4 Advantages Centre-mounted process valve for safe and secure industrial usage Economic initial equipment with single-piece housing construction Body complete Elastomer-lined with seat ring as multifunctional sealing ele- Option: Version DIN - DVGW Gas DIN - DVGW Wasser with certification 10 8 Process valve KG 2 · KG 4 The Types Type KG 2 [ DN 50 – DN 500 ] Wafer type butterfly valve for installation between flanges DIN EN 1092-1, PN 10/16, ANSI 150. Type KG 4 [ DN 50 – DN 500 ] Lug type butterfly valve for installation...

Open the catalog to page 10

Safe and secure automation with the interchangeable top flange G E FA - M U LT I T O P 3 Additional O-ring seal Seals the stem coupling from outside 2 Two-piece, blow-out proof stem ensures a stable mount for the valve disc 3 Primary seal integrated in the seat, ensures a pressure-stable seal to the outside, additional labyrinth design, seals on the stem 4 4 5 Body single-piece with locating holes or threaded cam as lug type version 6 Valve disc with full high finish 7 6 5 7 8 8 Seat ring exchangeable multifunctional sealing element, maintenance-free, long life-span, reliable seal in seat,...

Open the catalog to page 11

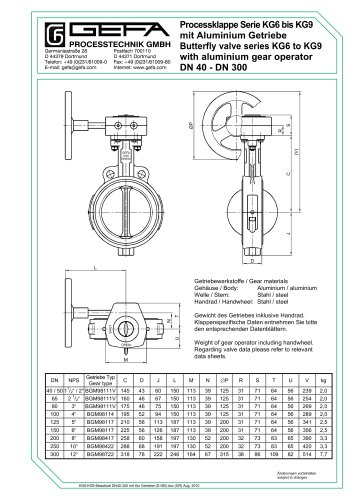

P T F E - l i n e d B u t t e r f l y va l v e S e r i e s K Centrally mounted valve disc with solid, zero play disc/stem connection Body fully PTFE-lined (min. 3 mm) Permanent seal with full chemical resistance Very aggressive and corrosive media are transferred safely Option: Pharmacentical version / cavity free with glazed PTFE face towards flange 12 Type KG 6 [ DN 50 – DN 300 ] Technical Data: Wafer type butterfly valve for installation between flanges DIN EN 1092-1, PN 10/16, ANSI 150. Two-piece body, self-centring, single-piece valve disc and stem, sealed to 10 bar. Face to face...

Open the catalog to page 12

Safe and secure automation with the interchangeable top flange G E FA - M U LT I T O P Automation • Standard mounting flange conforming to DIN 3337 • Direct-mount actuation without interruption to the valve stem • Variable and exchangeable for any size of actuator • Actuator protected against leakage 1 3 Two-piece body Standard construction length; very easy to service, simple replacement of the internal parts only possible with the two-piece body construction 2 equire m y r ts Qu lit en a VDI 2440 c o n t r o l 1 v a l v e s Technical specifications qu alit y 4 c PTFE seat ring in solid...

Open the catalog to page 13

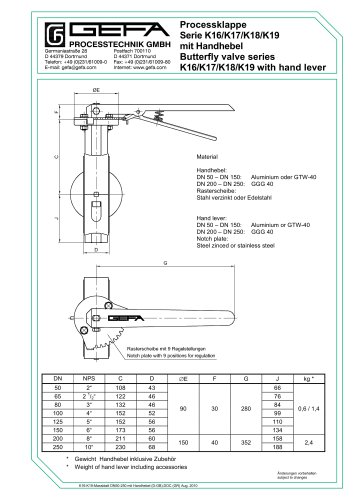

P T F E - l i n e d B u t t e r f l y va l v e S e r i e s K Type K 16 [ DN 350 – DN 600 ] Type K 18 [ DN 350 – DN 600 ] Technical Data: Wafer type butterfly valve for installation between flanges DIN EN 1092-1, PN 10/16, ANSI 150. Two-piece body, self-centring, single-piece valve disc and stem, sealed to 10 bar. Face to face dimensions: DIN EN 558-1 series 20 (DIN 3202-K1) Top flange: ISO 5211 Test: EN12266-1, P10/P11/P12-A DIN 3230, T3 - BA/BO-1 DIN 3230, T5, T6 Technical Data: Lug type butterfly valve for installation between flanges DIN EN 1092-1, PN 10, ANSI 150. Two-piece body with...

Open the catalog to page 14All GEFA Processtechnik catalogs and technical brochures

-

Valve technology catalogue

44 Pages

-

ED

1 Pages

-

MC-SuperNova

11 Pages

-

ED series

1 Pages

-

DG1

1 Pages

-

KG8

1 Pages

-

K16

1 Pages

-

K07

1 Pages

-

K08

1 Pages

-

K17

1 Pages

-

K19

1 Pages

-

KG2

1 Pages

-

KG7

1 Pages

-

HG7 with gear box

1 Pages

-

HG7 DN 350 - 500

1 Pages

-

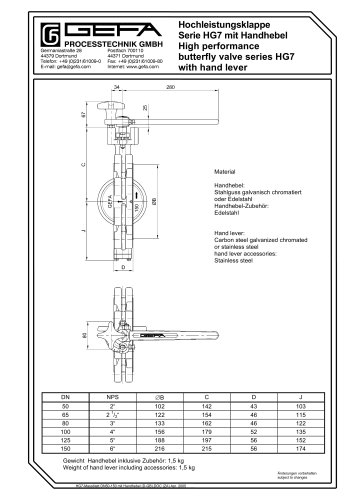

HG7 with hand lever

1 Pages

-

HG7 series DN 50 - 300

1 Pages

-

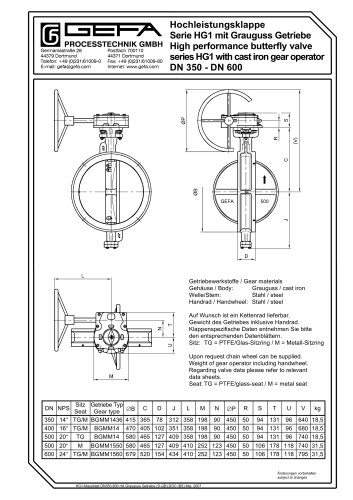

HG1 DN 350 - 600

1 Pages

-

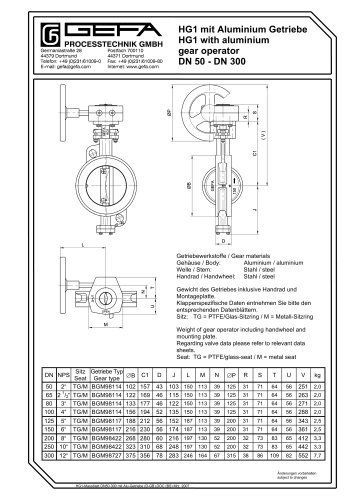

HG1 with gear box

1 Pages

-

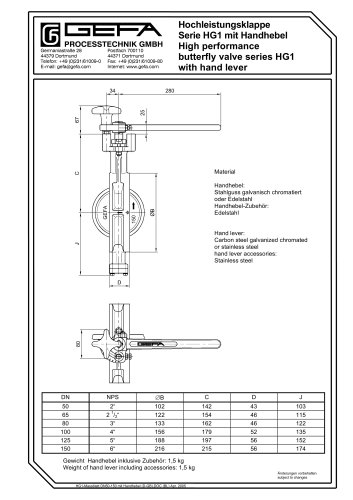

HG1 with hand lever

1 Pages

-

HG1 DN 600

1 Pages

-

DH1 DN350 - 500

1 Pages

-

HG1 DN 50 - 300

1 Pages

-

Serie KG9

1 Pages