Website:

GE Compressors

Website:

GE Compressors

Group: GE Energy

Catalog excerpts

BAKER HUGHES I a GE company An operator in Fort McMurray, Alberta, deploys steam assisted gravity drainage (SAGD) and electric submersible pump (ESP) technology to produce their field. Due to sand production in some of the wellbores, the ESP pumps’ life expectancy is reduced. In this case, the ESP pump, installed in a high-temperature, shallow and total vertical depth (TVD) well, ceased to function after pulling sand through. Previous attempted bailer trips to recover these sands in similar wellbores in the area proved to be unsuccessful and did not remove adequate sand volumes in an efficient way. In search of successful services to properly clean the wellbore, Baker Hughes, a GE company (BHGE), was requested to run the vectored annular cleaning service (VACS™). The BHGE operations team designed a 2 %-in. VACS wellbore cleanup bottomhole assembly (BHA) including, float subs, 3 %-in. tubing, junk catchers, and a variety of shoes to accommodate the wellbore conditions and requirements. The BHA was small enough to fit comfortably alongside the guide string, did not require high pump rates to achieve effective suction, and had a large enough shoe inside diameter (ID) and junk catcher area to catch any large debris. The BHA was deployed with a service rig, slanted to 35° at surface. The VACSPredictor™ prejob planning software aided in designing the most applicable BHA set-up to ensure suction, maintain wellbore control, and optimum sand recovery. Approaching the top of the trouble area, pump rates and pressures were established and the clean-out operations initiated. Since the VACS technology was able to clear the wellbore ahead of the string, the end of the trouble area was reached without much need to reciprocate the workstring. Upon inspection of the BHA at the surface, sand and scale were trapped in the chamber and within the junk catchers. An estimated total of 94 gal (355L) of clean sand and scale debris was recovered, the equivalent of 7.9 joints of 3 %-in. EUE tubing. The customer expressed satisfaction with these results based on previous unsuccessful clean-out history in the area and expected sand returns. With the simplicity of the operation, low pump rates required, and thorough clean-out results, the customer intends to use this technology for future wellbore clean-up needs in the SAGD fields. Challenges • Recover lost production in high-temperature, shallow TVD wellbore • Clean out alongside guide string stuck in wellbore Results • Recovered 94 gal (355 L) of sand in one run, the equivalent of 7.9 joints out of 12 • Performed operation in under 4 hours • Zero hours of NPT and no HSE incidents bhge.com Copyright 2019 Baker Hughes, a GE company, LLC ("BHGE"). All rights reserved. The information contained in this document is company confidential and proprietary property of BHGE and its affiliates. It is to be used only for the benefit of BHGE and may not be distributed, transmitted, reproduced, altered, or used for any purpose without the express written consent of BHGE. Baker Hughes reserves the right to make changes in specifications and features shown herein, or discontinue the product described at any time without notice or obligation. Contact your BHGE representative for the most current information. The Baker Hughes logo, VACS, and VACSPredictor are trademarks of Baker Hughes, a GE company, LLC. GE and the GE Monogram are trademarks of the General Electric Company. 79028

Open the catalog to page 1All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

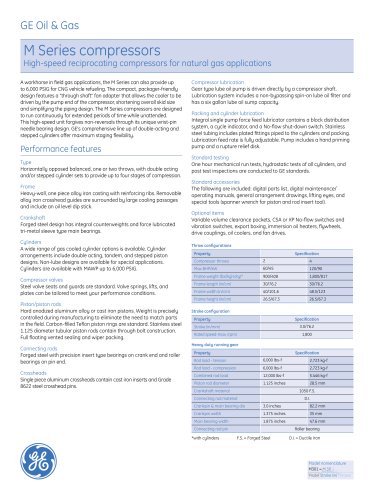

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

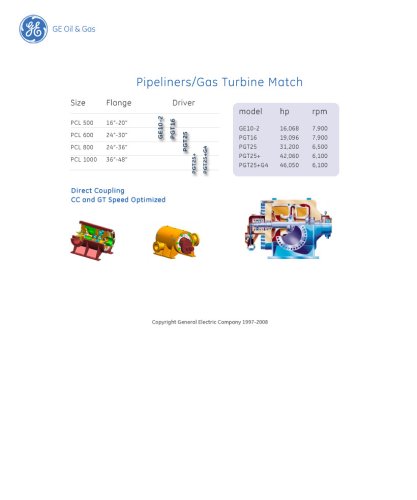

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages