Website:

GE Compressors

Website:

GE Compressors

Group: GE Energy

Catalog excerpts

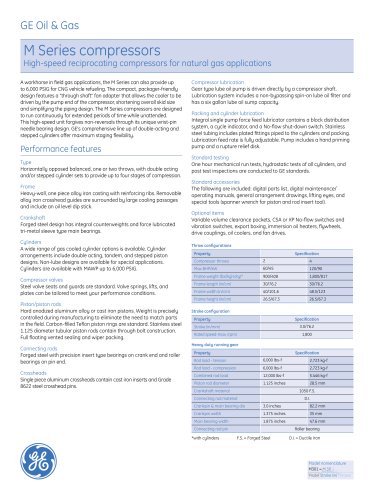

High-speed reciprocating compressors for natural gas applications A workhorse in field gas applications, the M Series can also provide up to 6,000 PSIG for CNG vehicle refueling. The compact, packager-friendly design features a “through shaft” fan adapter that allows the cooler to be driven by the pump end of the compressor, shortening overall skid size and simplifying the piping design. The M Series compressors are designed to run continuously for extended periods of time while unattended. This high-speed unit forgives non-reversals through its unique wrist-pin needle bearing design. GE’s comprehensive line up of double-acting and stepped cylinders offer maximum staging flexibility. Performance features Type Horizontally opposed balanced, one or two throws, with double acting and/or stepped cylinder sets to provide up to four stages of compression. Frame Heavy-wall, one piece alloy iron casting with reinforcing ribs. Removable alloy iron crosshead guides are surrounded by large cooling passages and include an oil level dip stick. Crankshaft Forged steel design has integral counterweights and force lubricated tri-metal sleeve type main bearings. Cylinders A wide range of gas cooled cylinder options is available. Cylinder arrangements include double acting, tandem, and stepped piston designs. Non-lube designs are available for special applications. Cylinders are available with MAWP up to 6,000 PSIG. Compressor valves Steel valve seats and guards are standard. Valve springs, lifts, and plates can be tailored to meet your performance conditions. Piston/piston rods Hard anodized aluminum alloy or cast iron pistons. Weight is precisely controlled during manufacturing to eliminate the need to match parts in the field. Carbon-filled Teflon piston rings are standard. Stainless steel 1.125 diameter tubular piston rods contain through bolt construction. Full floating vented sealing and wiper packing. Connecting rods Forged steel with precision insert type bearings on crank end and roller bearings on pin end. Crossheads Single piece aluminum crossheads contain cast iron inserts and Grade 8622 steel crosshead pins. Compressor lubrication Gear type lube oil pump is driven directly by a compressor shaft. Lubrication system includes a non-bypassing spin-on lube oil filter and has a six gallon lube oil sump capacity. Packing and cylinder lubrication Integral single pump force feed lubricator contains a block distribution system, a cycle indicator, and a No-flow shut-down switch. Stainless steel tubing includes plated fittings piped to the cylinders and packing. Lubrication feed rate is fully adjustable. Pump includes a hand priming pump and a rupture relief disk. Standard testing One hour mechanical run tests, hydrostatic tests of all cylinders, and post test inspections are conducted to GE standards. Standard accessories The following are included: digital parts list, digital maintenance/ operating manuals, general arrangement drawings, lifting eyes, and special tools (spanner wrench for piston and rod insert tool). Optional items Variable volume clearance pockets, CSA or XP No-flow switches and vibration switches, export boxing, immersion oil heaters, flywheels, drive couplings, oil coolers, and fan drives. Throw configurations Property Compressor throws Frame weight (lbs/kg) (dry)* Frame length (in/cm) Frame width (in/cm) Frame height (in/cm) Stroke configuration Property Stroke (in/mm) Rated speed-max. (rpm) Heavy duty running gear Property Crankshaft material Crankpin & main bearing dia Crankpin width Main bearing width *with cylinders Model nomenclature M301 = M 30 1 Model Stroke (in) Throws

Open the catalog to page 1

Cylinders for the M Frames Series MAWP PSIG Cylinder bore - inches Cylinder cooling Flange rating Double acting Crank end single acting SACE SAHE SAHE, MOC, MPS M30 Head end single acting L = Nitrided Liner - field replaceable D.I. = Ductile Iron SAHE = Tandem cylinder - Single Acting Head End a, b, c, etc. Designates cylinders having identical XYZ flange NL = No Liner F.S. = Forged steel SACE = Tandem cylinder - Single Acting Crank End dimensions to assist interchangeability and package C.I. = Cast Iron piping standardization (1) The 1.25" piston can be trimmed to add 14% or 25% additional...

Open the catalog to page 2

High-speed reciprocating compressors for natural gas applications The H Series compressors (formerly models HPD, HPDD, HPSS, HPDS) are designed to run continuously for extended periods of time while unattended. This high-speed unit forgives non-reversals through its unique wrist-pin needle bearing design. GE’s comprehensive line-up of double-acting and stepped cylinders offer maximum staging flexibility. A workhorse in field gas applications, the H Series can also provide up to 6,000 PSIG for CNG vehicle refueling. The compact, packager-friendly design features a “through shaft” fan adapter...

Open the catalog to page 3

Cylinders for the H Frames Series MAWP PSIG Cylinder bore - inches Cylinder cooling Flange rating Double acting H30 Crank end single acting Head end single acting SACE SAHE L = Nitrided Liner - field replaceable D.I. = Ductile Iron SAHE = Tandem cylinder - Single Acting Head End a, b, c, etc. Designates cylinders having identical XYZ flange NL = No Liner F.S. = Forged steel SACE = Tandem cylinder - Single Acting Crank End dimensions to assist interchangeability and package C.I. = Cast Iron piping standardization (1) The 1.25" piston can be trimmed to add 14% or 25% additional clearance (1)...

Open the catalog to page 4

High-speed reciprocating compressors for natural gas applications GE Oil & Gas A Series (formerly designated the FE332D) natural gas compressors provide mid-range horsepower performance in a compact, high-speed design. The 3.5 inch stroke is an ideal fit for today’s 1,800 rpm drivers. Built for high performance, GE A Series compressors are ideal for high-pressure applications such as gas re-injection, CNG vehicle fueling, and high-pressure fuel gas boosting. They offer a wide range of cylinders and rated discharge pressures as high as 6,000 PSIG. Performance features Type Engineered for...

Open the catalog to page 5All GE Compressors catalogs and technical brochures

-

Iron & Steel

8 Pages

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

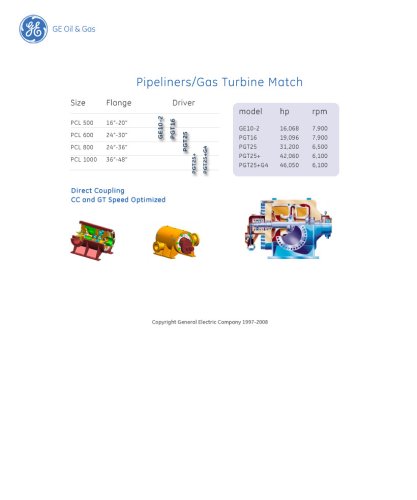

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages