Website:

GE Compressors

Website:

GE Compressors

Group: GE Energy

Catalog excerpts

Smarter. Cleaner. Industry. Iron & Steel 2017 STEAM POWER SYSTEMS INDUSTRY PRODUCT CATALOG

Open the catalog to page 1

IRON & STEEL, NON-FERROUS AND MINING INDUSTRY SOLUTIONS GE has supplied air quality control solutions (AQCS) to the industry for more than 70 years. Tailored to industry needs, our cost-effective solutions minimize air pollution from ore to finished products, while increasing energy efficiency and recovery of waste heat to reduce the energy demand of the plant. Engineered Solutions GE has the engineering capabilities and the process specialists to deliver integrated solutions that are cost and energy efficient from the suction hoods to the stack. Reliable Operation Our systems have a proven...

Open the catalog to page 2

RAW MATERIAL PREPARATION Mining Secondary gas cleaning Dedusting Ducting, Hoods, Dampers, fans, stack IRON MAKING Blast Furnace Primary gas cleaning Dedusting Secondary ventilation Dedusting Ducting, Hoods, Dampers, fans, stack Sintering Plant Primary gas cleaning Dedusting, DeSOx, DeNOx Secondary gas cleaning Dedusting Heat Recovery Ducting, Hoods, Dampers, fans, stack Coke Oven Raw gas cleaning WESP Primary gas cleaning Dedusting, DeSOx Secondary gas cleaning Dedusting Ducting, Hoods, Dampers, fans, stack STEEL MAKING Basic Oxygen Furnance Primary gas cleaning Dedusting Secondary...

Open the catalog to page 3

Engineered Solutions to Meet Industry Needs We provide full turnkey solutions to meet your air quality control system requirements that fulfill the most rigorous emission regulations. With our dedicated engineering resources, we integrate our customized solutions directly into your plant. Our products meet the requirements of the European Union Industrial Emissions Directive (IED) and conform to its current Best Available Technology (BAT) reference document. We tailor our solutions to your requirements, ensuring that the products we recommend precisely meet your specifications. We also...

Open the catalog to page 4

COMPLETE SOLUTIONS Hot Quenching – Cost-Effective Emissions Control To treat PCDD/F, CO and VOC emissions, we combine a post combustion chamber with a hot quenching tower. This rapidly cools gases to below 250ºC after combustion and inhibits the novo-synthesis of PCDD/F. This technology reduces the need for extensive water-cooled ducting. We also supply forced draft coolers and radiant coolers (hair pin coolers) for primary gas cooling. Customized Enclosures for Noise Reduction We design and supply industry specific noise enclosures to dampen noise associated with melting and rotating...

Open the catalog to page 5

Technical Product Specifictions Dedusting For particulate removal, we offer electrostatic precipitators (ESP) or fabric filters (FF). Before dedusting the primary and secondary flue gases can be mixed in the main duct. ESP performance can be boosted with pulse energisation or SO3 injection to successfully reduce peak particulate emissions. Our fabric filters are specifically designed to meet the latest emission standards for the industry and can achieve particulate emissions as low as 1mg/Nm3. We supply both reversed air and pulse jet type filter systems. Our pulse jet fabric filters have...

Open the catalog to page 6

TECHNICAL PRODUCT SPECIFICATIONS Flue Gas Desulfurization Our portfolio for flue gas desulfurization reduces emission of SOx by adding dry or wet sorbent and converting it into an inert compound that can be safely disposed. Our FGD systems can be either dry or wet and achieve up to 95% removal of SOx. GE can design and deliver FGD systems for a large number of applications, including boilers, sinterbands and coke ovens. Our dry sorbent system is a low cost dry flue gas desulphurization system for low to medium SOx removal requirements. Our technology can use different sorbents depending on...

Open the catalog to page 7

www.gepower.com/steam * Trademark of General Electric Company. © 2017, General Electric Company and/or its affiliates. GE Proprietary Information. All Rights Reserved. No part of this document may be reproduced, transmitted, stored in a retrieval system nor translated into any human or computer language, in any form or by any means, electronic, mechanical, magnetic, optical, manual, or otherwise, without the prior written permission of the General Electric Company or its concerned affiliate. Information contained in this document is indicative only. No representation or warranty is given or...

Open the catalog to page 8All GE Compressors catalogs and technical brochures

-

2018 Power Services Catalog

111 Pages

-

Ajax? E-565 Gas Engine

2 Pages

-

Virtual Natural Gas Pipeline

5 Pages

-

Dresser? Turbine Meters

8 Pages

-

Portable diagnostics

3 Pages

-

Flexibility & performance

3 Pages

-

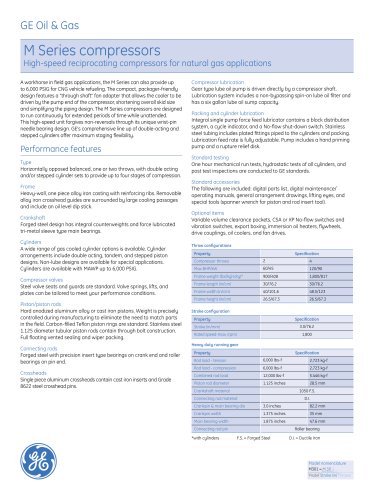

M Series compressors 2013

12 Pages

-

Roots Type H

11 Pages

-

M Series compressors 2010

12 Pages

-

High-speed solutions

6 Pages

-

CNG In A Box ? system

16 Pages

-

HE-S

2 Pages

-

API 618

2 Pages

-

Reciprocating Compressors

5 Pages

-

Roots * Turbo Blower

8 Pages

-

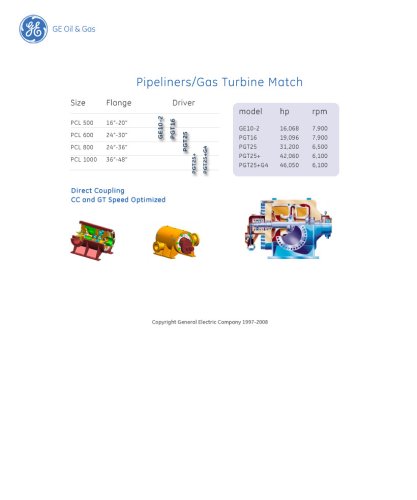

Pipeliners-Gas Turbine Match

1 Pages

-

global service

16 Pages

-

Centrifugal Compressors SRL

20 Pages

-

Centrifugal & Axial Compressors

28 Pages