Website:

GATES

Website:

GATES

Group: Tomkins

Catalog excerpts

Hose, Couplings & Equipment

Open the catalog to page 1

Table of Contents Section F or Oilfield Hose and Industrial Service Hose specifications, refer to the Gates Industrial Hose, Couplings & Equipment catalog (#39496-000). F or Hydraulic Hose and Equipment (Crimper) specifications, refer to the Gates Hydraulic Hose, Couplings & Equipment catalog (#35093).

Open the catalog to page 2

Gates Worldwide Locations Gates Corporation 1551 Wewatta Street, P.O. Box 5887 Denver, Colorado 80217-5887 Tel: (303) 744-5070 Fax: (303) 744-4540 Gates Rubber Co. (S) Pte. Ltd. No. 1 Changi South Street 3 Singapore 486477 Tel: 65-545-3800 Fax: 65-545-5322 Gates Canada, Inc. 225 Henry Street, Bldg. #8 Brantford, Ontario, N3S 7R4, Canada Tel: (519) 759-4141 Fax: (519) 759-0944 The Gates Group (Shanghai) Co., Ltd. No. 15 Hai Tang Street China-Singapore Suzhou Industrial Park Suzhou 215021, PR China Tel: 86-521-6761-9633 Fax: 86-512-6761-7184 Gates de Mexico, S.A. de C.V. Cerrada de Galeana...

Open the catalog to page 3

Super Choke & Kill or 15,000 W.P. Cementing Hose Request for Quote/Order Form 1. You must fill in all the information on the form in order to have your quote request/order processed. Any missing information can lead to costly delays in processing your request. If there are any questions about any part of the form or the application, check details with your oilfield customer, or call Ron Trujillo at 303-744-4735. The Date, Customer Name, P.O.# (if actual order) must be completed. Hose Type is Super Choke & Kill or 15,000 W.P. Cementing. Hose Size is the Hose I.D. Fill in Overall Length of...

Open the catalog to page 5

Quote/Order Form S C&K or CEMENTING HOSE REQUEST FOR QUOTE \ ORDER Hose Size Hose Type _ Safety Clamp & Chain □ S C&K Hose 15,000 psi W.P. - 22,500 psi test - Spec 475SL □ Cementing Hose 15,000 psi W,P, - 22,500 psi test - Spec 4758L Overall Length Working Pressure Add-On Fittings (will be furnished welded) | TPC: Working Pressure. Working Pressure _ Nominal Size Pipe Size_ HAMMER UNION-MALE SUB/NUT Pipe Size. Nominal Size. Nominol Size Working Pressure .Nominal Size. Working Pressure _ Pipe Size _ HAMMER UNION-MALE SUB/NUT Pipe Siie. Nominal Size. CERTIFICATIONS /STANDARDS * =Request...

Open the catalog to page 6

Technical Information

Open the catalog to page 7

Progressive Products Rapidly Advancing

Open the catalog to page 8

Gates High Performance Dynamic Pressure Rated Rotary Hose Assemblies To keep pace with rapidly advancing drilling technology involving directional drilling and down-linking with negative pressure pulses, Gates offers a high performance API 7K rated rotary hose assembly that far exceeds minimum standards. In addition to a high quality hose construction, the Gates system has a swage attached coupling with no seals to leak and no set screws to loosen with operation vibrations or epoxy to weaken with working temperatures above 180°F. Burst test results significantly exceed the API 7K minimum...

Open the catalog to page 9

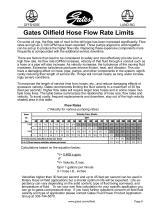

Gates Oilfield Hose Flow Rate Limits On some oil rigs, the flow rate of mud to the drill pipe has been increased significantly. Flow rates as high as 3,100 GPM have been reported. Three pumps aligned to work together can be set up to produce the higher flow rate. Replacing these expensive components more frequently is compounded with the additional service downtime. There are factors that need to be considered to safely and cost effectively provide such a high flow rate. As flow rate (GPM) increases, velocity of that fluid through a conduit such as a hose or a pipe will also increase. As...

Open the catalog to page 10

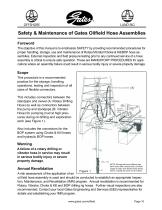

Safety & Maintenance of Gates Oilfield Hose Assemblies Foreword The objective of this manual is to emphasize SAFETY by providing recommended procedures for proper handling, storage, use and maintenance of Rotary/Vibrator/Choke & Kill/BOP hose assemblies. External inspection and field pressure testing prior to any continued service of a hose assembly is critical to ensure safe operation. These are MANDATORY PROCEDURES for applications where an assembly failure could result in serious bodily injury or severe property damage. Scope This procedure is a recommended practice for the storage,...

Open the catalog to page 11

Safety & Maintenance of Gates Oilfield Hose Assemblies Storage 1. ompletely drain hose assembly before C placing in storage. Caution: Care should be exercised to prevent mishandling. Crushing or kinking of hose can cause severe damage to reinforcement. If this occurs, remove hose from service and then contact local Gates representative for further advice. 2. henever feasible, store hose in original W shipping crate. This will provide extra protection against the deteriorating effects of solvents, corrosive liquids, ozone and sunlight. Hose should be stored so coils are in a horizontal...

Open the catalog to page 12

Safety & Maintenance of Gates Oilfield Hose Assemblies Recommended Practices Where applicable, the following recommended practices should be used on rotary drilling and vibrator hose. A. Overall Hose Length 1. ncludes standard connector and/or I special adapters (see Figure 3). B. Rotary Hose Length 1. n order to avoid kinking hose, the I hose length and standpipe height should be such that when raising or lowering, as in making mouse hole connections, the hose must not exceed the rated minimum bend radius at the swivel when it is at its lowest drilling position and at the standpipe when it...

Open the catalog to page 13

Safety & Maintenance of Gates Oilfield Hose Assemblies D. Vibrator Hose Length 1. It’s important to choose a vibrator hose having an inside diameter equal to that of the pump discharge fitting and the fluid supply line inside diameters. This is necessary to allow free flow of fluid and to avoid turbulence or unnecessary abrasion of the hose tube. The length of vibrator hose should be given careful consideration. It should be long enough to prevent kinks near the couplings, yet short enough to prevent kinks in the radius near the middle of the hose. E. Hose Connections 1. ine pipe threads...

Open the catalog to page 14

Safety & Maintenance of Gates Oilfield Hose Assemblies Operations Caution: Care should be exercised during operation to prevent crushing or kinking of hose. Crushing or kinking can cause severe damage to cable reinforcement. If this occurs, remove hose from service and test as outlined in the “Field Test Pressure” section. A. Working Temperature 1. orking temperature should not W exceed the rating of the hose. Temperatures encountered higher than the rated temperature will reduce hose life expectancy. B. After Coolers 1. ompressors should always be C equipped with after coolers to lower the...

Open the catalog to page 15All GATES catalogs and technical brochures

-

HYDRAULIC & FLEET HOSE PRODUCTS

769 Pages

-

FLEETRUNNER® BELTS

2 Pages

-

MICRO-V® ARAMID

2 Pages

-

GATES INDUSTRIAL POWER TRANSMISSION

302 Pages

-

POWERGRIP® GT®3

199 Pages

-

POWERGRIP™ GT4™

2 Pages

-

Hydraulics Catalog

769 Pages

-

Engine Cooling Fan Module

2 Pages

-

Heater Hose Assemblies

2 Pages

-

iLok™ Coupling

6 Pages

-

Coolant Outlets

2 Pages

-

Thermostats and Caps

2 Pages

-

Turbo Charger Steel Tube Kit

2 Pages

-

Fan Pulley Brackets

2 Pages

-

Accessory Belt Drive System

2 Pages

-

FleetRunner®Belts

2 Pages

-

Micro-V®Aramid

2 Pages

-

DriveAlign® Laser Tool

2 Pages

-

Electric Water Pumps

1 Pages

-

BladeRunner® Belts

2 Pages

-

Hose Management System

4 Pages

-

2017 products catalog

253 Pages

-

EFG4K

1 Pages

-

EFG5K

1 Pages

-

BRASS PRODUCTS

190 Pages

-

HOSE, COUPLINGS + EQUIPMENT

229 Pages

-

2015 PRODUCTS CATALOG

629 Pages

-

INDUSTRIAL ENGINE PRODUCTS

137 Pages

-

government & Military Catalog

11 Pages

-

Grounds Maintenance Equipment

750 Pages

-

Automotive Hydraulics & Fleet hose

684 Pages

-

2012 MASTER PRODUCTS CALOG

100 Pages

-

Mining Products Catalog

136 Pages

-

Hydraulic Products Catalog

593 Pages

-

Powersport Applications 2013

75 Pages

-

Fleet & Heaw-Dutv Applications

733 Pages

-

Water pump catalog

302 Pages

-

ED

1 Pages

-

Nov9061

1 Pages

-

high temp hose

6 Pages

-

TH7 TH8

4 Pages

-

Cotton Cleaner Belt

2 Pages

-

Gates Metric Power Belts

4 Pages

-

BELT PRODUCTS

92 Pages

-

PowerBand® Belts

4 Pages

-

PowerGrip® Twin Power®

2 Pages

-

PowerGrip® GT®2

2 Pages

-

2012 products catalog

275 Pages

-

2012 INDUSTRIAL HOSE CATALOG

229 Pages

Archived catalogs

-

Industrial Hose product catalogue

192 Pages

-

Specialty Synchronous Belts

36 Pages