Website:

Galbiati Group S.r.l.

Website:

Galbiati Group S.r.l.

Group: Galbiati Group

Catalog excerpts

PRESSES The Press and Notching Machine division at Galbiati Group is specialized in the design and construction of high speed presses and notching machines. It is dedicated to blanking and notching of magnetic laminations to produce rotors and stators for electric motors. Experience, production capability, and professionalism supported by a highly-specialized machine shop allow Galbiati to build high-precision, reliable machines. Certified Quality Certified Quality The precision required for the production for the major structural parts of our presses is guaranteed by the inspections we...

Open the catalog to page 3

EP3 Press for High Speed Blanking Magnetic Laminations Full blanking force under any condition The flywheel is anchored to the side frame by means of a bushing in order to avoid stressing the shaft. Oversized, it allows blanking operations to be performed with the rated machine tonnage at very low speeds, lower than those allowed by other presses of equal force. The stiffness of the press bed also guarantees increased die life, a feature particularly advantageous when using hard metal dies. Die Inspection The quick lift, standard on all EP3 presses, allows the upper half of the die to be...

Open the catalog to page 4

Maximum performance for high speed blanking over the range from 250 to 650 ton Rated capacity Stroke Length Slide Adjustment Quick lift Bolster Area Upright Opening EP3 Press for High Speed Blanking Lamination Deep Hole Drilling Machines by Galbiati Group

Open the catalog to page 5

EP4 Press for High Speed Blanking Lamination The EP4 press for high speed lamination blanking is the natural evolution of the EP3 press. A few significant innovations improve production quality and productivity. In particular, dynamic penetration control and overhead shaft assembly have been introduced. Dynamic Penetration Control During blanking, the penetration of the slide can vary due to the elongation of the connecting rods (resulting from heating of the machine). This is particularly critical when stacking laminations. The EP4 press allows you to adjust the penetration during blanking...

Open the catalog to page 6

High performance for high speed blanking and penetration control Rated capacity Stroke Length Slide Adjustment Quick lift Bolster Area EP4 Press for High Speed Blanking Lamination Deep Hole Drilling Machines by Galbiati Group

Open the catalog to page 7

Other Features: Full Blanking Force Under Any Condition The flywheel is fastened to the side upright by means of a bushing in order to avoid stressing the crankshaft. The oversized flywheel guarantees blanking operations to be performed within the rated press capacity, at very low speeds, lower than those allowed by other presses of equal force. The stiffness of the press bed also guarantees increased die life, a feature particularly advantageous when using hard metal dies. Die Inspection The quick lift feature (standard on all EP4 presses) allows the upper half of the die to be opened,...

Open the catalog to page 8

Galbiati Group - Engineering & Machining 23848 Oggiono (LC) Via Cà Bianca Pascolo, 26 Italy | Tel +39 341 2633260 Presses and Notching Machine Division: presses@galbiatigroup.it http://galbiatigroup.it/presses-notching-machines

Open the catalog to page 12All Galbiati Group S.r.l. catalogs and technical brochures

-

Coil Processing Lines

15 Pages

-

ZEISS MMZ-G 30 60 25

12 Pages

-

Pressa EP4

6 Pages

-

Ultrasonic Test Certificate

1 Pages

-

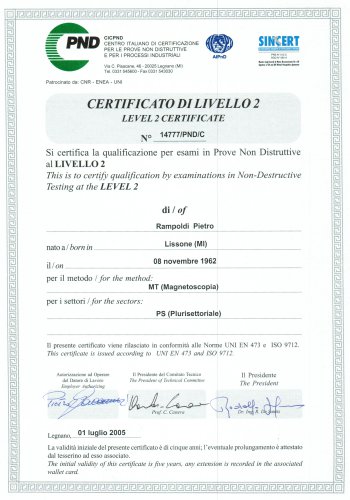

Quality Certificate

1 Pages

-

Galbiati Group

28 Pages

-

Custom Built Machines

12 Pages

-

Gear Reducers

16 Pages