Website:

Galbiati Group S.r.l.

Website:

Galbiati Group S.r.l.

Group: Galbiati Group

Catalog excerpts

TENSION LE V ELLING S Y STEM ( t l S ) SLITTING LINES SINGLE UNITS

Open the catalog to page 2

Viganò International processing lines are equipped with an e f f icie nt au tom ation s ystem designed to increase productivity and reduce maintenance shut-downs. In fact, our equipment is designed and manufactured to ensure e a se of m ainte nance and a high availability of spare parts. Our machines are suitable for the processing of various types of materials, in particular: h ot-rolle d s te e ls , cold-rolle d s te e ls , pickle d steels, h ig h-s tre ngth s te e ls , s tainle s s s te e ls , alu m in i um, c o ppe r and b ras s . Thanks to decades of international field experience, we...

Open the catalog to page 3

we have been chosen by AXIS S.A BRASIL | GALVAPRIME MExICO | HERNANDEZ EDELSTAHL GERMANy | INOX MARKET SERVICE holland | TAD INOX SERVICE BV Netherlands | SIDERVER ITALy | SMS INNSE HABAS TURKEY | SYTCO GAZPROM RUSSIA | TATA STEEL FRANCe | AISI ACOS INOXIDAVELS PORTuGAL | ARCELOR MITTAL DS OXYBEL Belgium | GIUSEPPE e F.lli BONAITI SPA ITALy | SIDERURGICA ASTICO Spa ITALy | STEEL WAY SRL ITALy | IRON SPA ITALy | MARCEGAGLIA SPA ITALy | METALSIDER SPA ITALy | APERAM STAINLESS SERVICE AND SOLUTIONS SRL FRANCe ITALy | POSCO ITPC SPA ITALy | THYSSENKRUPP AST ITALy | COMMIT SIDERURGICA Spa ITALy...

Open the catalog to page 4

In a global market, based on scale econonomies, it is necessary to develop “strong muscles”. For this very reason,Viganò International has chosen to join Galbiati Group . A partnership characterised by continuity, with a focus on enhancing the Company’s presence across the Italian territory and in foreign markets. Galbiati Group is an Italian company internationally recognised for the quality of its machining, mechanical engineering and construction capabilities. The Company’s specialisations in the machining of large parts has allowed Galbiati Group, since 1962, to operate with great...

Open the catalog to page 5

P ROCESSED MATERIALS carbon steel, stainless steel, aluminium and alloys, brass, copper and ferrous metals Each cut-to-length line (cross-cutting) is specifically designed according to our customers’ needs. Depending on the characteristics of the materials to be COIL THICKNESS processed, each line may differ in terms of: - application of personalised know-how BLANKING LINES - final quality of the surface This type of CTL is used in the auto m ot iv e a n d hom e app li a nc es i nd us t r ie s . It is designed to process stainless steel and/or carbon steel coils less than 1,000 mm wide,...

Open the catalog to page 6

Pinch-roll with calamine/dust aspiration hood and portal frame with pressure roll and anti-coil break roll. Straightener: carries out a first stretching of the coil fibres and breaks the calamine scales on strip surface. Rough out brushing machine: removes residual calamine and dust from the surface, upper and lower, of the strip. End shear: cuts the defective head and tail of the coil. Edge trimmer and scrap chopper: trims to size the rough edges of the coil; the scrap is then chopped down. Four high finishing/levelling machine: relieves the stress from the coil to ensure flatness, making...

Open the catalog to page 7

This system preserves and ensures the elastic-plastic characteristics of the material, elevating the levelling process to high standards. The material is stabilised and stress relieved, suitable for laser cutting, for automatic machining and punching; the tail of the coil is levelled at the same level of quality achieved in the centre of the coil. The TLS requalifies coils with above average defects, while the sophisticated software and the multiple configurations available allow the successfull processing of coils commonly considered as “Non processable”. The introduction of a tension...

Open the catalog to page 8

P ROCESSED MATERIALS carbon steel, stainless steel, aluminium and its alloys, brass, copper and ferrous metals COIL THICKNESS Slitting lines designed to ensure highest standards of quality and productivity while processing different materials such as stainless steel, carbon steel (hot rolled and cold rolled), pre-painted steel and galvanized, aluminium, copper and brass, from the lowest Designed to optimise quality and productivity, in full compliance with operator safety regulations, ensuring the quality of work and with particular attention to the simplification of maintenance activities....

Open the catalog to page 9

Coil loading car with decoiler and edge control device. Coil loading and decoiling section and unwinding with strip centring. Decoiler, pinch-roll and coil opening table, end shear and scrap collecting box. Dragging of the head of the coil and cutting the head of the coil to remove defects. Plastic film applicator pinchroll with plastic film rollstock, circular blade shears with blade changing system, extensible table with scrap conveyor. Plastic film application, replacement of cutting equipment with automatic locking, coil cutting into strips and conveying of swarf scrap into the looping...

Open the catalog to page 10

DEC OILERS Capacity up to 40 tons. FLYING (a) AND ROTARY SHEARS ( b ) Used to cut the coils to size. The machines are designed to The solutions proposed by Viganò International are different and vary according to the type of material to be processed, of the ultimate technology, designed to achieve high In order to satisfy different requirements of the customers, performance as well as to guarantee the maximum precision Viganò International offers different solutions: movable overhanging mandrel, movable opposite mandrels, with cones Viganò International shears represent the quintessence...

Open the catalog to page 11

spare part s avai l ab i l i t y Mechanical failures managed by the presence with specialised technicians. intervention action plan Electronic failures managed by Teleservice. Technical evaluation of anomalies. Viganò International boasts decades of experience in assistance and maintenance with great satisfaction of our customers. cu stom spare part s Our technicians undergo continuous training in order to be able to operate on machines of all brands. In addition, they are carefully trained to operate paying particular attention to safety. We are able to perform maintenance on machines and...

Open the catalog to page 12All Galbiati Group S.r.l. catalogs and technical brochures

-

ZEISS MMZ-G 30 60 25

12 Pages

-

Pressa EP4

6 Pages

-

Ultrasonic Test Certificate

1 Pages

-

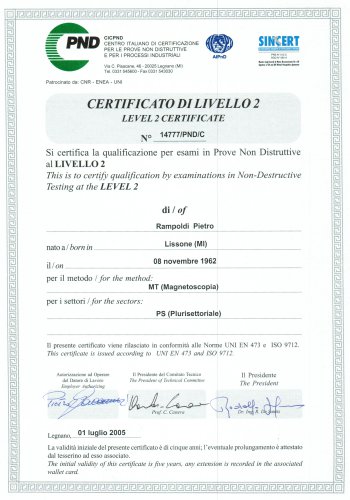

Quality Certificate

1 Pages

-

Galbiati Group

28 Pages

-

Presses for Blanking Laminations

12 Pages

-

Custom Built Machines

12 Pages

-

Gear Reducers

16 Pages