Website:

Fusion Incorporated

Website:

Fusion Incorporated

Catalog excerpts

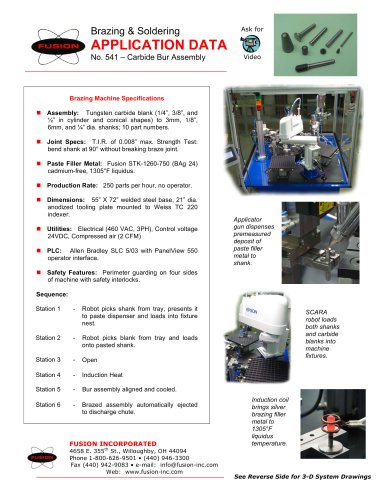

Brazing & Soldering APPLICATION DATA No. 546 – Liquid Line Drier Assembly Wire Feed Brazing Machine Specifications Assembly: 25.4 mm dia. copper tube to copper drier and brass valve. Wire Filler Metal: Silvaloy 2M, 2Ag/91.50Cu/6.50P, 1190°F (645°C) liquidus. Production Rate: 125 parts per hour, one operator. Dimensions: 72” X 72” welded steel base, 42” dia. stainless steel tool plate cover, stainless water trough, Weiss TC 220 indexer. Utilities: Electrical 460/3/60, 5 amp, Control voltage 24VDC, Gas 96 CFH, Oxygen 192 CFH, Water 1 GPM, Compressed Air 5 CFM. PLC: Allen Bradley Micrologix 1500 with PanelView Plus 600 Interface Panel. Tooling: Adaptable to accommodate (4) part styles; water cooled. Options: Nitrogen purged through assembly during heating to control internal oxidation; sensor detects nitrogen flow. Gas flux to promote filler metal flow and reduce base metal discoloration. 100 gallon Water Recirculating System. Precision gas/oxygen heat pattern distributes filler metal evenly throughout tube joint areas. Safety Features: Perimeter guarding on 3 sides of machine with safety interlocks. Light curtain for E-stop function. Sequence: Station 1 Load/Unload Assembly Gas-Oxygen Heat Gas-Oxygen Heat/Wire Feed Water Cool FUSION INCORPORATED 4658 E. 355th St., Willoughby, OH 44094 Phone 1-800-626-9501 • (440) 946-3300 Fax (440) 942-9083 • e-mail: info@fusion-inc.com Web: www.fusion-inc.com Brazed assembly is water cooled for safe operator unloading.

Open the catalog to page 1All Fusion Incorporated catalogs and technical brochures

-

DISPENSABLE FLUX PRODUCTS

2 Pages

-

No. 545 - Shotgun Assembly

2 Pages

-

Brazing & Soldering

1 Pages

-

BRAZE MATE Model 200

1 Pages

-

"Braze Mate" Model 150

1 Pages

-

BRAZE MATE Model 100

1 Pages

-

APPLICATION DATA

1 Pages

-

Paste Brazing & Soldering Alloys

20 Pages

-

Induction Atmosphere Brazing

2 Pages

-

Carbide Bur Brazing Machine

2 Pages

Archived catalogs

-

Paste Brazing & Soldering Alloys

10 Pages

-

PISTOL GRIP APPLICATOR GUN

1 Pages