Website:

Flowserve SIHI Pumps

Website:

Flowserve SIHI Pumps

Group: Flowserve

Catalog excerpts

SIHIprime - Side Channel Pumps Self-priming, segmental type with very low NPSH TECHICAL DATA Capacity: Delivery head: max. 120 °C max. 180 °C for high temperature design (higher temperatures on request) Casing pressure: Shaft sealing: mechanical seal Flange connections: anti-clockwise (when seen from the drive end) Protection classification: APPLICATION The Sterling SIHI CEH-X pump is a self-priming side channel pump capable of handling gas along with the medium and operates at a low noise level. The CEH-X pumps are used for problem-free pumping of clean liquids at unfavourable suction side conditions. They are also very suitable for positive suction heads below 0.5 m. Different material possibilities with uniform dimensions and performance characteristics as well as the standard exchangeable components are used for the construction. The CEH-X pumps are particularly recommendable for applications in the pharmaceutical, chemical or petrochemical market as well as in the plastic or oil industry. Because of its low NPSH and positive suction head the CEH-X is very suitable for the pumping of liquefied gases and liquids under vapour pressure like condensate, refrigerant, boiler feed or LPG. CONSTRUCTION Casing pressure Maximum 40 bar from -40 °C up to +120 °C. Maximum 32 bar from +120 °C up to +180 °C. Pressure stages for temperature as per DIN EN 1333. Please observe Technical rules and safety regulations: Casing pressure = inlet pressure + delivery head at minimum pump capacity. Position of branches Axial suction branch, discharge branch points radially upwards. Flanges The CEH-X pumps have a retaining stage, combined with the low NPSH stage, to avoid the dry running by controlling the liquid level in the pump. This design is especially developed for the handling of liquids under vapour pressure or when pumping from underground tanks. The CEH-X pumps are used for bottom off-loading of liquids under vapour pressure. Flanges in accordance with DIN EN 1092-2 / PN 40. Flange design as per DIN 2512 with groove or drilled according to ANSI 150 or 300 lbs is basically possible. Bearing DESIGN One grease lubricated, greased for life, ball bearing according to DIN 625 and one liquid surrounded sleeve bearing. The pumps of the SIHIprime range are side channel pumps having segmental type construction. The construction of the CEH-X pump is a centrifugal combined system. This combination pump is suited with a centrifugal stage in serial connection before the side channel stages to obtain a more favourable NPSH. Rotation direction The program comprises, currently, 3 sizes (1200, 3100 and 3600) each with 1-8 stages. The existing material design allows an optimum rating for the respectively desired performance range and the pumping medium. The applied hydraulic components are from our modular side channel system (interchangeability of parts). Anti-clockwise, when looking from the drive end. Shaft sealing The shaft is sealed by a mechanical seal according to DIN EN 12756, with quench connection. The shaft sealing is also available in a design suitable for heating or cooling of the mechanical seal and a double mechanical seal (back-to-back as well as tandem) design is possible on request. PUMP TECHNOLOGY CEH-X PIII/11 05/2015

Open the catalog to page 1

CEH-X Material design Material design GS Cast Iron/ GL Cast Iron Pos. Stainless steel Vane wheel impeller Suction casing Discharge casing Shell casing First suction intermediate Side channel intermediate Last discharge intermediate Centrifugal impeller Mechanical seal casing Cooling insert Bearing cover Bearing bush * Bearing bush in Antimony Carbon is only used in high temperature design Casing seal The casing sealing is done by o-ring gaskets compatible with the handled medium. Drive By electric motor, type of construction IM B3. According to the area of usage, we can supply motors of any...

Open the catalog to page 2

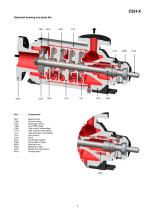

CEH-X Sectional drawing and parts list Bearing bush Suction casing Discharge casing Low NPSH stage First suction intermediate Side channel intermediate Last discharge intermediate Shell casing Shaft Centrifugal impeller Vane wheel impeller Bearing cover Mechanical seal Mechanical seal casing Cooling insert

Open the catalog to page 3

CEH-X Operating principle The CEH-X pump is a combined system side channel pump. It is suited with a low NPSH centrifugal impeller (1) placed before the side channel stages. This NPSH inducer stage delivers enough pressure to overcome the entrance pressure loss of the first side channel stage or the required NPSH. 1 A side channel stage consists of: A suction intermediate (2), A discharge intermediate including the side channel (3), A vane wheel impeller located between the 2 intermediates (4). The fluid entrance goes through the suction hole (5). The turning of the vane wheel impeller...

Open the catalog to page 4

CEH-X Performance range General conditions Liquid: Density: Viscosity: Temperature: Atmospheric pressure: Characteristic tolerances The Side Channel pumps are not submitted to any normalized test tolerances. Here under are our acceptance values: Capacity ± 9% - Delivery head ± 7% - Power + 10%. Measuring standard According to ISO 5198. Note: 1) When using a liquid containing gas, a safety margin has to be added.

Open the catalog to page 5

CEH-X Dimension chart and pump set drawing CEH-X 1201 … 1208 The weight of the pump will be approximately 6% higher when using stainless steel. General: Values are valid for water ρ = 1 kg/dm3 and υ = 1 cSt. Design tolerances: Capacity± 9% - Delivery head ± 7% - Power + 10%. 1) For EExe II T3 motors. Notes: 2) For every pump set in ATEX area. 3) Dimensions are depending on the used motor trade mark.

Open the catalog to page 6

CEH-X Performance curves CEH-X 1201 … 1208 An additional safety head must be added when handling a liquid containing gas.

Open the catalog to page 7

CEH-X Dimension chart and pump set drawing CEH-X 3101 … 3108 The weight of the pump will be approximately 6% higher when using stainless steel. General: Values are valid for water ρ = 1 kg/dm3 and υ = 1 cSt. Design tolerances: Capacity± 9% - Delivery head ± 7% - Power + 10%. 1) For EExe II T3 motors. Notes: 2) For every pump set in ATEX area. 3) Dimensions are depending on the used motor trade mark.

Open the catalog to page 8All Flowserve SIHI Pumps catalogs and technical brochures

-

Type NHK and SHK

24 Pages

-

SIHIsanivac 400, 800, 1000

4 Pages

-

PL 325 M

14 Pages

-

PL 91 M, PL 126 M, PL 161 M

16 Pages

-

SIHI ® Gas separation

8 Pages

-

SIHI Liquid Ring Compressors

8 Pages

-

Side Channel Pumps

12 Pages

-

LPG Solutions

12 Pages

-

SIHISuperNova ZHND 032160

14 Pages

-

SIHImodular PL 251 M

13 Pages

-

LEM 26, LEM 51

7 Pages

-

LEM 325, LEM 425

8 Pages

-

Applications and Products

9 Pages

-

Series MFS, 7,200 m³/h

2 Pages

-

Sludge Mixer MFS

2 Pages

-

Mixed Flow, Volute Casing Pump

11 Pages

-

Volute casing pumps

26 Pages

-

Non-clogging Pump

19 Pages

-

Volute casing pump CBT

11 Pages