Website:

FlexLink

Website:

FlexLink

Group: Coesia

Catalog excerpts

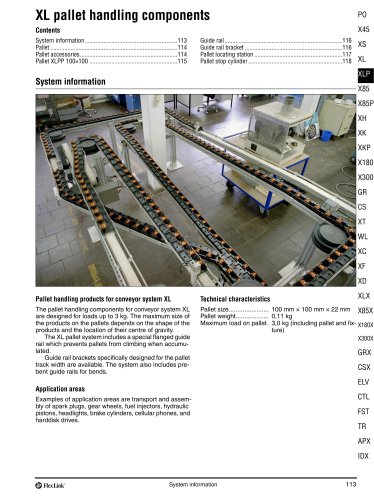

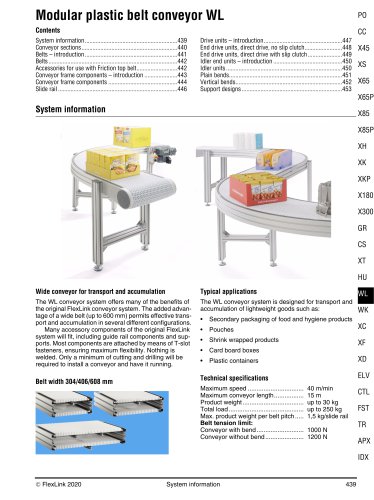

Modular plastic belt conveyor WK System information Wide conveyor for transport and accumulation Typical applications The added advantage of a wide belt (up to 1200 mm) permits effective transport and accumulation in several different configurations. Many accessory components of the original FlexLink system will fit, including guide rail components and supports. Most components are attached by means of T-slot fasteners, ensuring maximum flexibility. Nothing is welded. Only a minimum of cutting and drilling will be required to install a conveyor and have it running. The WK conveyor system is designed for transport and accumulation of lightweight goods such as: • Gear wheels Technical specifications Belt width 150/225/300/600/900/1200 mm Cylindrical products 40 m/min 20 m up to 30 kg up to 250 kg 2,5 kg/slide rail 1250 N System information

Open the catalog to page 1

Belts – introduction Tools and accessories No special tools are required. The belt is lubrication-free. A new belt running on new slide rails, however, will need a few hours of running-in before it runs perfectly smoothly. For applications where absolutely smooth running is essential from start, use a silicone or teflon based lubricant. Ordering information The belt is delivered in assembled 1 m lengths one plastic rod and two guide clips are included. To calculate the total length required, remember to add for belt consumed by the idler and drive units. Links and plastic rods The belt...

Open the catalog to page 2

Belts guide clip Belt guide clip, right Belt guide clip, left

Open the catalog to page 3

Conveyor sections The modular plastic belt conveyor in six widths – 150, 225, 300, 600, 900, 1200, – straight sections. Conveyor sections

Open the catalog to page 4

Conveyor frame components - introduction Technical specifications Typical friction between chain and slide rails after run-in: Conveyor frame structure Frame profiles and cross bars Conveyor frame sections consist of the following compo- • Frame profile (3 m or cut to any length from 0,5 m up • Centre support profile • Fastener yoke • Mounting hardware Conveyor dimensions tiHHUHHHi yy y^ij^H^ii yy yy IHHHUIWHHHI yy yy yy u□ij_I HIJ IIII HO yy IHMHH^ Usable belt width B (mm) Standard belt WKTP 1B Each 3 m frame section consists of two frame profiles connected by four cross bars. The conveyor...

Open the catalog to page 5

Conveyor frame components Conveyor frame profile Conveyor beam, W=150 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm) Conveyor beam, W=225 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm) Conveyor beam, W=300 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm) Conveyor beam, W=600 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm Conveyor beam, W=900 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm Conveyor beam, W=1200 Length 3 m (3030 ±5 mm) Length to order (500- 3000 mm WKCB 3A150 WKCB LA150 WKCB 3A225 WKCB LA225 WKCB 3A300 WKCB LA300 Frame profile Length 3 m...

Open the catalog to page 6

Conveyor frame components (continued) Aluminium rivets for anchoring of slide rail Aluminium rivets 4 mm for XKX180/X300 conveyors, brown Extra slide rail in plain bends must be anchored using plastic screws due to lack of space for the rivet crimping tool. Note. Must be ordered in multiples of 250. The following components from FlexLink structural system XC are used to build the crossbar. XCBL 3×44 XCAF 44 XCAN 6* Beam for cross bar Fastener yoke Slot nut for M6 screw *Note. Must be ordered in multiples of 10 Support beam 44×44, lightweight Beam 44 mm × 44 mm Lightweight design Aluminium,...

Open the catalog to page 7

Sprocket wheels Ordering information Drive units with motors must be specified using the webbased configurator. The configurator provides detailed information and step-by-step guidance in the specification process. A product code string is generated, containing the specification details. See next page for examples of code strings. The WK system includes direct driven units with or without slip clutch. Available motors include variable speed types (V) as well as fixed speed motors (F). Drive units without motors can be ordered using the designations in the catalogue. • Connecting strips are...

Open the catalog to page 8

End drive units, direct drive, no slip clutch End drive unit Fixed/variable speed*, width 150 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 225 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 300 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 600 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 900 mm Without motor:...

Open the catalog to page 9

End drive units, direct drive, slip clutch End drive unit L/R End drive unit Fixed/variable speed*, width 150 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 225 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 300 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 600 mm Without motor: Transmission on left side Transmission on right side End drive unit Fixed/variable speed*, width 900 mm Without...

Open the catalog to page 10

Idler end units – introduction PO Chain guidance at end of conveyor The idler end unit is used to guide the chain from the return side of the conveyor up to the top side with a minimum of friction. The chain is guided by two or more idler X45 wheels on a common, rotating shaft supported by ball bearings. XS Number of idler wheels vs. conveyor width Width Idler wheels Ordering information • Connecting strips are included with the idler end units. Slide rail must be ordered separately. Idler units WK WKEJ 150 B WKEJ 225 B WKEJ 300 B WKEJ 600 B WKEJ 900 B WKEJ 1200 B Idler end unit, width 150...

Open the catalog to page 11

Support designs Support components The illustrations on this page show recommended supports for the conveyor. All supports are built using components from FlexLink structural system XC. See main catalogue section Conveyor support components for more information. Height and width of supports Type 1, 2 WK150 We recommend using a drill fixture for Type 1 supports. Item no. 8050040 Drill fixture Suggested support components Beam support bracket Angle bracket Cross beam Drill fixture Support designs

Open the catalog to page 12All FlexLink catalogs and technical brochures

-

Conveyor system XW

20 Pages

-

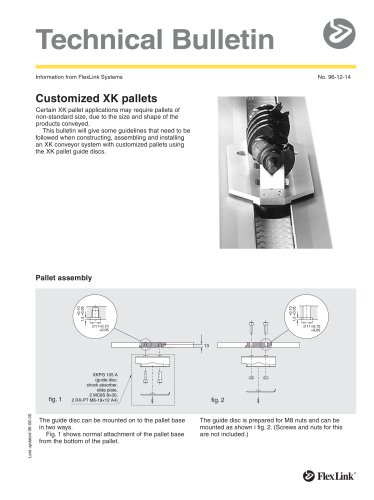

Customized XK pallets

2 Pages

-

WLX222

16 Pages

-

Food and dairy

8 Pages

-

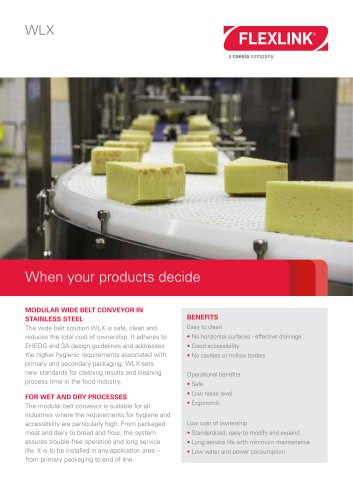

WLX

2 Pages

-

Enclosures and safety guards

158 Pages

-

PRODUCTION FLOW SOLUTIONS

8 Pages

-

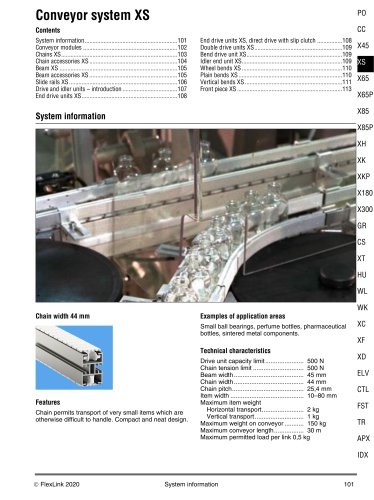

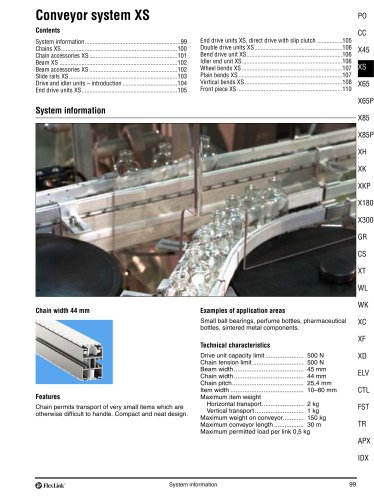

Conveyor system XS

14 Pages

-

Elevator

4 Pages

-

Modular plastic belt conveyor WK

14 Pages

-

Modular plastic belt conveyor WL

16 Pages

-

Conveyor system X65

32 Pages

-

Product overview

498 Pages

-

Customized XK pallets

2 Pages

-

GENIUS PCB HANDLING SYSTEM

66 Pages

-

Product Catalogue

160 Pages

-

Configurable Components

20 Pages

-

SMART PCB handling system

12 Pages

-

GENIUS line

8 Pages

-

SMART line

4 Pages

-

Pallet system XTH

4 Pages

-

Conveyor system WL374X

16 Pages

-

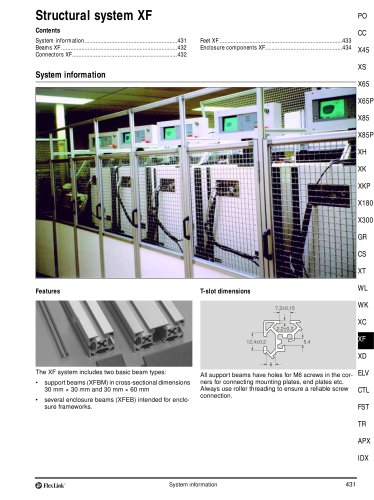

Structural system XF

8 Pages

-

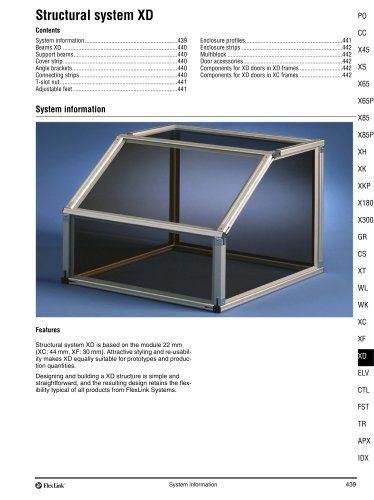

Structural system XD

4 Pages

-

Spiral elevator

2 Pages

-

Pallet system XK

16 Pages

-

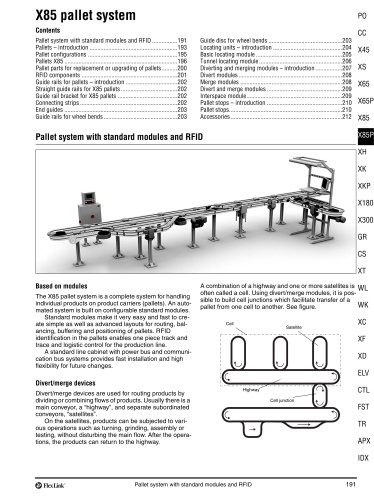

Pallet system X85

22 Pages

-

Conveyor system WL526X

16 Pages

-

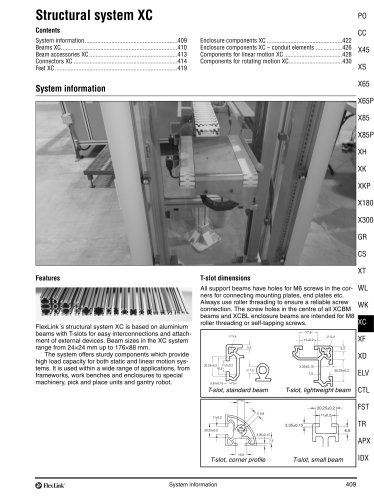

Structural system XC

22 Pages

-

Conveyor system XLX

8 Pages

-

Pallet system XT

50 Pages

-

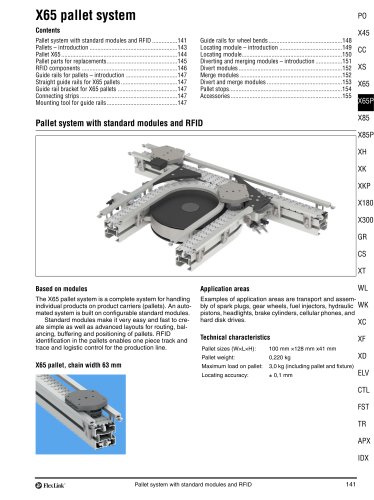

Pallet system X65

16 Pages

-

Conveyor system WL678X

16 Pages

-

Conveyor system X300X

14 Pages

-

Conveyor system X180X

14 Pages

-

Conveyor system X85X and X85Y

18 Pages

-

Profile system MS+

320 Pages

-

Product overview

24 Pages

-

Conveyor system XW

20 Pages

-

Conveyor System WL

16 Pages

-

Conveyor System X300

10 Pages

-

Conveyor System X180

10 Pages

-

Conveyor System XK

20 Pages

-

Conveyor System XH

20 Pages

-

Conveyor System X85

34 Pages

-

Conveyor System X65

30 Pages

-

Conveyor System XS

12 Pages

-

Conveyor System X45

48 Pages

Archived catalogs

-

Conveyor System XL

28 Pages