Website:

DONALDSON

Website:

DONALDSON

Group: Donaldson Company

Catalog excerpts

FILTER CARTRIDGE VALIDATION FOR ULTRADEPTH FF, MF, SMF

Open the catalog to page 1

2 TABLE OF CONTENTS Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 Materials and construction . . . . . . . . . . . . . . . . . . . . . . . 4 Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Differential pressure of dry and clean filter elements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Degree of fractional separation of particles . . . . . . . . . .7 Differential pressure as a function of increasing oil exposure time . . . . . . . . . . . . . . . . . . 9 – 21 Differential pressure of the fully...

Open the catalog to page 2

The ultrafilter oil removal filter elements of types FF , MF and SMF consist of a sandwich construction of ultrairD binder-free borosilicate microfibre fleece which is covered by a worldwide patent. These high-efficiency filters are used to remove the oil, water and contaminants which are present in compressed air, pressurised gases, air and gases under atmospheric conditions and under vacuum. The filter elements are of a robust construction and designed to operate reliably under tough operating conditions. The microfibre fleece is a depth filter material giving a void volume of 94%. Based...

Open the catalog to page 3

4 MATERIALS AND CONSTRUCTION End caps: Aluminium, material AlCuMgPb (standard; other materials upon request) Element connection: Up to an element size at 10/30: threaded connection From size 15/30 and above: tie rod Inner support sleeve: Stainless steel, material 1.4301 Outer support sleeve: Stainless steel, material 1.4301 The support sleeves are made of flat-rolled expanded metal, thus providing a very high effective filtering surface area. Inner support fleece: Cerex Outer support fleece: Cerex Filter material: Binder-free borosilicate microfibre fleece End cap bonding: Epoxy O-ring...

Open the catalog to page 4

To extract the small droplets of liquids contained in compressed gases, the flow through the filter element is from the inside to the outside. The enhanced design provides filtration in two stages. Coarse contaminants are held back by the pre-filtering medium. Oil and condensate droplets are retained by the depth filter material. The droplets coalesce and are carried to the outer foam sock. The retained condensate trickles down the foam sock and accumulates at the bottom of the housing. These high-efficiency filter elements are also available in OPERATION 5 a special version for use in...

Open the catalog to page 5

6 DIFFERENTIAL PRESSURE OF DRY AND CLEAN FILTER ELEMENTS Test arrangement The air is compressed by a screw compressor, purified and dried by an oilfreepacD. For measurement purposes, a filter housing of type AG 0072 with a 10/30 filter element has been used. A flow regulator, placed upstream of the filter being tested, is used to set the various flow levels that are then measured downstream by a variable gas flowmeter. The differential pressure across the filter and housing is measured and recorded at the different flow rates. Upon completion of the test cycle, the initial volume flow is...

Open the catalog to page 6

7 DEGREE OF FRACTIONAL SEPARATION OF PARTICLES The degree of fractional separation, i.e. the degree of separation of particles having almost the same size (monodisperse), as a function of the particle size is to be determined. Test arrangement and measurement procedure The test is carried out for 04/20 filter elements. The particle material selected was di-2 ethylhexyl sebacic acid (DES). The aerosol is produced by Sinclair - La Mer generator, mixed with particle-free air and then passed through either the test nit or a bypass line at a volume flow of 12 m3/h at 1 bar gauge. This method...

Open the catalog to page 7

9 Analysis by the Technical University of Dresden of the high-efficiency oil removal filter elements made by ultrafilter gmbH All analysis of the performance of the differential pressure and oil aerosol retention characteristics of high-efficiency oil removal filter elements of types FF, MF and SMF at the Technical University of Dresden (Germany) has been agreed with ultrafilter gmbh. The following sections describe the test conditions and measurement procedures. The results obtained are listed for each type of element. 1. Test arrangement The basic arrangement used for the test is shown...

Open the catalog to page 9

10 A twin-piston compressor (1) is used to generate the compressed air under the following conditions: ˜ Operating pressure 7 bar ˜ Volume flow, adjustable within the range of 200 to 1,000 Nm3/h (the standard conditions are defined at an absolute pressure of 1 bar and a temperature of 20 °C) A heat exchanger (2) mounted downstream cools the compressed air to a temperature of between 20 and 30 °C. A filter housing of type AG 0072 and 10/30 filter elements were used for the measurements. Samples are taken at the inlet and the outlet of the filter (3) under isokinetic conditions for the oil...

Open the catalog to page 10

11 The mass flow through the filter is measured by an orifice flowmeter (measurement point 03) in compliance with standard DIN 1952. 2. Measurement procedure The spectrum of the oil droplets, measured directly at the inlet of the filter by the cascade impactor and absolute filter measuring device, indicates a high oil content within the droplet size range of 0.7 to 1.2 ìm. The oil concentration measured at the inlet of the filter is approximately 4 mg/Nm3. From the oil concentration at the inlet and the oil concentration at the outlet, measured by the absolute filter measuring device, the...

Open the catalog to page 11

12 Three elements with different lot numbers for each type of filter element were independently examined under the same operating conditions. Type descriptions and lot numbers are listed below Oil removal element Lot number FF 10/30 93 08 151 93 09 364 93 12 106 MF 10/30 93 10 212 93 12 327 94 01 174 SMF 10/30 93 06 215 93 09 033 93 11 158 3. Measurement results The results of the measurements have been compiled for each type of element and incorporate the individual points of the test programme described in section 2. The results shown are mean values taken from the 3 test runs for each...

Open the catalog to page 12All DONALDSON catalogs and technical brochures

-

Air Intake Systems

8 Pages

-

Clean DEF Solutions

4 Pages

-

Clean Fuel & Lubricant

32 Pages

-

Exhaust System Solutions

2 Pages

-

Pressure Control Systems

2 Pages

-

Innovative Fuel Systems

2 Pages

-

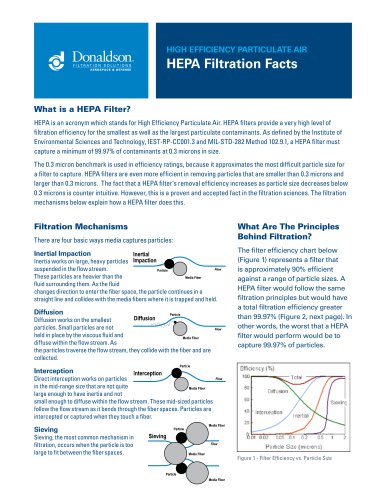

HEPA Filtration Facts

2 Pages

-

AEROSPACE & DEFENSE

4 Pages

-

pOWERCO RE® air cleaners

8 Pages

-

Donaldson Strata™ Tubes

4 Pages

-

PG-EG 0006 – 0192

6 Pages

-

(P)-GS N

6 Pages

-

Minerals Brochure

4 Pages

-

Metals Brochure

4 Pages

-

Industrial Filtration

10 Pages

-

Pharma Industry - Tetratex

2 Pages

-

Microfiltration

2 Pages

-

Power Generation

8 Pages

-

Vacuum Cleaner and Sweepers

4 Pages

-

Hydraulic Filtration

320 Pages

-

LDV FILTER KITS

4 Pages

-

Engine Liquid Filtration

154 Pages

-

Cabin Air Filtration

2 Pages

-

ToriT®powercore®dusT collecTors

16 Pages

-

PLEATED BAGS

3 Pages

-

DALAMATIC ® DUST COLLECTORS

12 Pages

-

HPK05

6 Pages

-

Engine Intake Systems

171 Pages

-

Ultrabev P-PF-BEV

4 Pages

-

Capsule Filters

8 Pages

-

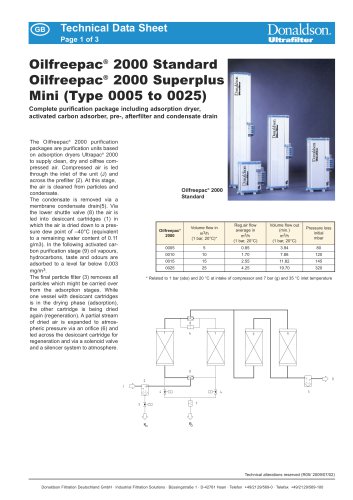

Oilfreepac® 2000 Standard

3 Pages

-

Clean Fuel Cart X011407

1 Pages

-

Clean Fuel Cart X011408

1 Pages

-

Leakage Detector DLD

2 Pages

-

SG Standard Filter Housing

7 Pages

-

Bulk Oil Cleaniness Levels

1 Pages

-

Clean Fuel Cart X011431

1 Pages

-

Venting Product Overview

2 Pages

-

Sensor Vents

2 Pages

-

Vacuum Cleaners and Sweepers

4 Pages

-

Chemicals Brochure

4 Pages

-

DPF Thermal Regenerator IOM

16 Pages

-

Adsorbent Breather Assembly

2 Pages

-

Adsorbent Pouch Filter

2 Pages

-

Adsorbent Breather Filter

2 Pages

-

Bulk hP

4 Pages

-

ULTRAPOREX SB

2 Pages

-

LITHOGUARD®

2 Pages

-

BSMmax

2 Pages

-

Valves & Solenoids

2 Pages

-

Fluid Analysis

12 Pages

-

DT filter

22 Pages

-

Off-Line Filtration

14 Pages

-

Sight Glasses

1 Pages

-

Strainers

4 Pages

-

Valves

6 Pages

-

Breathers

14 Pages

-

TT15/30/60

2 Pages

-

SP100/120

4 Pages

-

Low Pressure Filters

64 Pages

-

WL16

4 Pages

-

Medium Pressure Filters

38 Pages

-

W613

4 Pages

-

FPK02

6 Pages

-

HPK02

4 Pages

-

High Pressure Filters

86 Pages

-

panel filter

1 Pages

-

GDX

4 Pages

-

DISK DRIVE SEALS

2 Pages

-

ADSORBENT LABEL FILTER (ALF)

2 Pages

-

Exhaust Product

186 Pages

-

Hydraulic Filtration

374 Pages

-

Engine Liquid Filtration

132 Pages

-

Oil/Water Separators

6 Pages

-

SYNTEQ XP M/S

2 Pages

-

Synteq XP

4 Pages

-

Ultrac? AK

2 Pages

-

Ultrapoly? PE

2 Pages

-

ULTRAC A

2 Pages

-

Dryer Package Filters

2 Pages

-

SG Compressed Air Filters

2 Pages

-

AG Compressed Air Filters

2 Pages

-

Rotary Valves

10 Pages

-

Unimaster® Dust Collector

4 Pages

-

Unicell Dust Collectors

6 Pages

-

Downflo Dust Collectors

6 Pages