Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

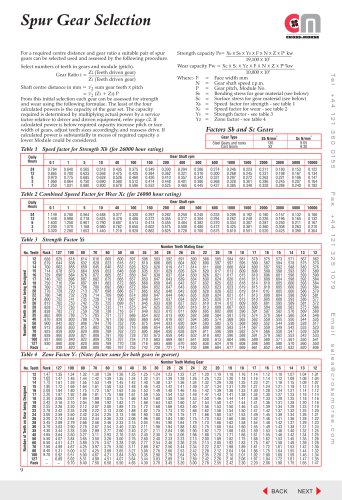

Catalog excerpts

Cross & Morse Torque Limiters Cross & Morse Torque Limiters are low cost protection devices that limit torque in a drive system by slipping when a preset value is exceeded, in order to:Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 Prevent machine and drive damage. Eliminate costly machine downtime. The Torque Limiter is a protective device that limits torque transmitted in a drive system by slipping when a preset value is exceeded as a result of shock load, overload or machine jam. It automatically re-engages, when the overload is removed, no setting being required, Torque is transmitted by spring loaded friction faces, the value being preset by adjustment of the spring force by simple setting of the adjustment nuts and bolts. The Torque Limiter is suitable to use with sprockets, gears, pulleys or a flange plate as the centre member clamped between the friction facings. The Torque Limiter is not a new product with Cross & Morse. In 1949 Morse introduced the first spring loaded, friction type protective device which was developed to today’s line of products consisting of 7 sizes, the models 200M to 700M being the most popular units. To further extend the capabilities of our products a new metric series of clutches, consisting of 6 sizes from M30 to M280 has been added, to cater for higher torque applications, and areas where space is limited. As originator of the Torque Limiter, Morse gained vast experience in the design and application of these units as trouble free and long lasting protective devices. Many thousand units have been fitted to conveyors, mechanical handling equipment and agricultural machines. Morse Torque Limiters incorporate design features for long life and reliability. Correct Spring Selection and Ratings Email: sales@crossmorse.com Torque Limiter capacities are directly proportional to the spring force applied to the friction surfaces and it is a simple matter to increase capacity by increasing spring force - but not without a sacrifice. The higher the unit load or pressure (psi) on the friction surfaces, the quicker the friction facings will deteriorate as they slip against the pressure plates and centre member. Morse ratings are realistic and are consistent with optimum spring loads and face pressures that permit longer slip time, maintain re-engagement at pre-set torque, and provide long-lasting protection. The spring is designed so that its force varies little over a wide deflection range at the rated capacity of the torque limiter. This assures load re-engagement near the pre-set torque level as the friction facing wears. It is characteristic of a disc spring that it is more unstable and erratic in the lower end of its load vs. deflection curve; Morse therefore established minimum torque ratings consistent with spring characteristics. Cross & Morse Torque Limiters offer you the following Benefits: • Simple Design • Minimum Maintenance • Economical • Easy Adjustment • Corrosion Resistant • Compact • Wide Torque Range • Infinite Torque Adjustment Settings • Dependable The incorporation of an inexpensive Cross & Morse Torque Limiter improves machine design, safeguards production, and minimises the downtime so ensuring increased productivity and profits. 3 INDEX

Open the catalog to page 1

Standard Torque Limiters Original Morse Series Torque Limiters Dimensions *Model Stock Finish bores Max Bore with Std Keyway †Standard Bush Lengths (Ref.) *M1 Torque Limiters Fitted One Disc Spring. M2 Torque Limiters Fitted Two Disc Springs. †Torque Limiter supplied standard without Bush, which is supplied with Platewheel. If Bush required, specify on order which length (size) required. For procedure to select Torque Limiters refer to page 6. For range of standard platewheels refer to page 7. (1) Sizes 13 & 20 Torque Limiters for replacement purposes only Refer Metric sizes M200 - M280 for...

Open the catalog to page 2

Standard Torque Limiters Metric Series Torque Limiters To extend the range of torque capability a new series of Torque Limiters is offered providing both smaller and larger sized units with a range of 1.5 to 10,000 Nm. These units are all to metric dimensions, and as with the original series are available with a roller chain coupling for shaft to shaft connection. For Torque Limiter selection refer to page 6. Stock bore Max Bore with Std Keyway Approx. Weight Email: sales@crossmorse.com *Torque values can be halved by facing springs towards one another. †Torque values determined by...

Open the catalog to page 3

Torque Limiters Selection Selection Procedure 1. Determine if the Torque Limiter is to be mounted on input 4. Refer to pages 4 and 5, select size of Torque Limiter where Rated Torque slightly exceeds Slip Torque. Confirm Selected Torque Limiter will accept drive shaft diameter. 5. Using capacity below, confirm selection of Torque Limiter. For machines under constant supervision or with motor overload sensors the 10 sec values should be used. For unmanned machines combination of torque and speed should always be within power ratings over 5 min to avoid deterioration of components parts due...

Open the catalog to page 4

Torque Limiters Platewheels Stock Machined Platewheels for BS Roller Chain Chain Pitch Outside Diameter Bush Length Bush Size Email: sales@crossmorse.com Bore Dia. over Bushing mm Catalogue Number For accurate torque setting and applications where slippage may be frequent, it is essential that a ground plate sprocket is used. Rated torque capacity can only be obtained with dry friction facings and a ground plate sprocket which has been run-in for 500 revolutions at 50% maximum torque rating for the single spring unit at a speed not exceeding 120 r.p.m. Fits Torque Limiter Number Morse...

Open the catalog to page 5

Torque Limiter Couplings Torque Limiter combined with Roller Chain Flexible Coupling Torque Capacity Nm Minimum Plain Bore Maximum Bore Limiter mm Sprocket Size *Weights are for Torque Limiter and Coupling unbored. Good Reasons to fit a Morse Torque Limiter on your Equipment. Design Protection for expensive components within the drive system or structural framework, gives longer machine life with increased reliability in service, and reduction of expensive downtime. Maintenance is reduced by the inherent protection offered by the torque limiter, which in itself is inexpensive, corrosion...

Open the catalog to page 6All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

Archived catalogs

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages