Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

Cross Safegard Overload Clutches The Safegard CS series Overload Clutches were developed to provide overload protection for the transmission of high torques within a compact unit. Directly interchangeable with other units in the market, this series offers low cost protection with a minimum of maintenance and long reliable service life. Safegard CS series are offered in two basic types, the standard type, available in 6 sizes for bores up to 65mm, with torque range of 2.5 to 1800Nm, see pages 24/25, provide optimum speed and torque capabilities; and the Mini type, available in 4 sizes for bores up to 45mm, with torque range 2.5 to400Nm, see pages 26/27, for a lower cost option for slower speed drives. Both types are available as basic clutch, and also as shaft couplings. The basic clutch is offered in three basic designs to enable alternate methods for connecting driven components. Four modes of drive operation are available, to suit the requirements of different applications, as outlined below, the principles of operation of each being detailed opposite. The Synchron CSY Clutch uses 7 rollers unequally spaced to provide the drive, ensuring that there is only one position of engagement of the drive, enabling full synchronisation between driver and driven shafts. The Safe Lift CSL Clutch has a retaining ring to prevent disengagement of the drive, but allowing sufficient movement to actuate a limit switch. This clutch is ideal on applications where components cross one another’s path, as synchronisation is maintained even when clutch has overloaded. The clutch also controls forward inertia drives. The Contact-Free CSZ Clutch totally disengages in the event of an overload, and requires an outside force to be re-engaged. This enables the clutch to be operated at higher speeds, and also to be used on applications where it is undesirable to stop the motor quickly. The requirement of an external force to re-engage ensures the machine can be checked prior to a restart. Safegard Series Clutches offer the following operating advantages: Long Service Life Cater for Frequent Overloads No Maintenance required Standardised Sizes Continued Operating Reliability Maintained Torque Accuracy Rapid Drive Disengagement Very Fine Torque Adjustment Email: sales@crossmorse.com The Safegard CSF Clutch uses a large number of equally spaced balls to provide the drive, and the clutch ratchets from one drive position to the next in the event of an overload. The design allows for high operating speeds, and the possibility to recapture drive in the event of an inertia created overload during starting, but do not provide any synchronisation between input and output. Method of Torque Adjustment Torque Adjustment on Safegard series Clutches is relatively simple process by the following procedure. Refer to diagram below, to adjust the Torque on a Clutch first remove screws 8 or 8A to permit free rotation of adjusting nut 7. If first adjustment manually tighten the adjusting nut 7 until it is in contact with the springs. Insert a C spanner ‘A’ into slots D, or a face wrench ‘C’ into holes D and tighten the nut clockwise to achieve desired Torque as indicated by the number of indents E moved. Replace screw 8 or 8A in thread hole G or G1 with adjusting nut positioned so this lines up with one of the holes H in the locking washer L

Open the catalog to page 1

Cross Safegard CS Clutch Types Safegard CSF Synchron CSY Te l : + 4 4 1 2 1 3 6 0 0 1 5 5 The Synchron clutch functions in much the same way as the Safegard, and has similar construction in except the balls 4a are replaced by seven rollers 4b. The rollers are unequally spaced so the clutch will only engage drive in one angular position, providing full synchronisation of the drive. When an overload occurs the balls ride up the indents pushing flange 2 back which will actuate limit switch 9. During overload conditions plain bearing 5 maintains concentricity and ensures free running. The balls...

Open the catalog to page 2All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

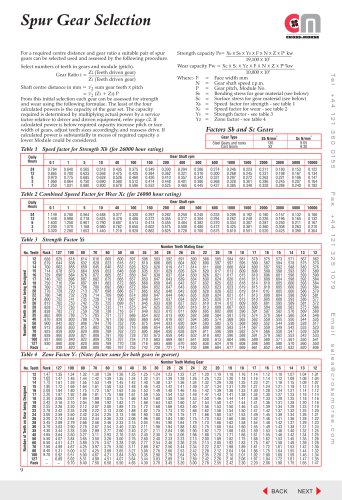

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

Clamping Elements RCK 10-12

2 Pages

-

'M' Series Sprag Clutches

2 Pages

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

Archived catalogs

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages