Website:

Cross & Morse

Website:

Cross & Morse

Group: Cross and Morse

Catalog excerpts

Clamping Elements Type RCK 10 to 12 These shaft clamping elements provide maximum torque transmission from a single unit, but, due to their large clamping surfaces clamping pressures are kept to reasonable levels. The design enables automatic centring between shaft and hub, and axial positioning of the hub does not change during clamping. Suitable for applications with high bending loads. For thin walled hubs, such as Conveyor Drums, the surface pressure on the hub can be reduced by reduction of the clamping torque applied to the Clamping Screws down to a minimum of 50%; the pressure on the outer hub and torque transmitted being reduced proportionaly, so that wall thickness of 12% of the internal diameter can be used. Recommended tolerances for full torque transmission both shaft and hub should be within the following tolerances: Shaft Hub Clamping surfaces to be finished to Rz ≤ 15 µm. These units ideal for mounting of wheels and belt conveyor pulleys. X = Distance required to remove screws, additional clearance for alan key may be required. Surface Pressure Clamping Screws Extraction Approx Shaft Hub Size Torque Screws Weight Ps Ph 2 2 kg Size N/mm N/mm Nm Email: sales@crossmorse.com These units are offered in three series. A light duty series RCK 10, a normal duty series RCK 11, and a Heavy duty series RCK 12 for maximum torque applications. *Minimum outside diameter of hubs manufactured in medium carbon steels with yield strength ≥ 320 N/mm . For hub types, and other materials, refer to page 3. For assembly and disassembly instructions refer to page 24.

Open the catalog to page 1

Clamping Elements Type RCK 11 and 12 Dimensions Dimensions mm Surface Pressure Clamping Screws Extraction Approx Shaft Hub Size Torque Screws Weight Ps Ph 2 2 kg Size N/mm N/mm Nm *Minimum outside diameter of hubs manufactured in medium carbon steels with yield strength ≥ 320 N/mm . For hub types, and other materials, refer to page 3. For assembly and disassembly instructions refer to page 24. Email: sales@crossmorse.com

Open the catalog to page 2All Cross & Morse catalogs and technical brochures

-

Taper Bushes

2 Pages

-

CS Mini Series Couplings

1 Pages

-

CS Standard Series Clutches

1 Pages

-

Sheargard Flexible Couplings

2 Pages

-

Sheargard Overload Clutches

4 Pages

-

PVR Paver Bearings

12 Pages

-

Stainless Steel Taper Bushes

2 Pages

-

Straight Racks

1 Pages

-

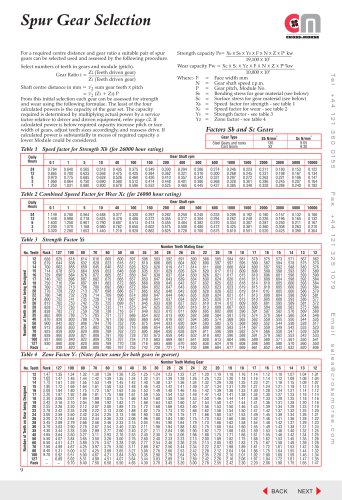

Spur Gears

4 Pages

-

Bevel and Mitre Gears

6 Pages

-

Torque Limiters & Couplings

6 Pages

-

KE Couplings

2 Pages

-

'L'Series - Jaw Couplings

2 Pages

-

Clamping Elements RCK 15

1 Pages

-

Clamping Elements RCK 13

1 Pages

-

SC Inverted Tooth Chain

3 Pages

-

HV Inverted Tooth Chain

7 Pages

-

Roller Chain Catalogue

3 Pages

-

Classical Timing Belts

3 Pages

-

'M' Series Sprag Clutches

2 Pages

-

Gold bearing products

209 Pages

-

Transmissions

90 Pages

Archived catalogs

-

Shaft Clamping Elements

28 Pages

-

Standard Gears

16 Pages

-

Shaft Couplings

22 Pages

-

Overload Protection Clutches

4 Pages

-

Sealmaster Bearings

4 Pages

-

Belt & Chain Tensioners

7 Pages

-

Freewheel Clutches

21 Pages

-

General Product Catalogue

12 Pages