Website:

CLARK Material Handling

Website:

CLARK Material Handling

Group: CLARK Material Handling

Catalog excerpts

TS20-33 G IC-PNEUMATIC LPG/DIESEL PNEUMATIC OR SOLID TYRES 2000 / 2500 / 3000 / 3300 kg 4000 / 5000 / 6000 / 6600 lbs.

Open the catalog to page 1

Almost maintenance free wet disc brakes • Enclosed and oil cooled for smooth operation = • Reduction in brake pedal effort - up to 50% compared to drum brakes. • Less lower maintenance costs compared to drum brakes, less downtime Wide, open foot steps with traction plates make entry/exit quick, easy and safe... from either side. Easily Serviceable, Extremely Dependable, Extremely Durable The CLARK GTS Series (GTS 20-33) impresses by a solid construction and high quality components. Offering a wet disc brake and a split transmission as a high quality standard this series is extremely...

Open the catalog to page 2

The large operator compartment´s, hood mounted hydraulic control levers, and seating are designed to maximize operator comfort, easily accommodates up to ninetyfive percentile of the world’s adult population. • Nested upright rails provide positive rail interlock and a narrow “column” to maximize the vision window. The overhead guard safety bars run parallel to the operator’s line of sight resulting in a clear, unobstructed view. Hydraulic cushioning valves provide silent staging of the rails to reduce shock during both lifting and lowering. Smooth Control Operator Confidence & Optimum

Open the catalog to page 3

GTS PRODUCTIVITY Protected front lights • For high productivity • Prevents potential damage • Optional LED-version for best illumination Split transmission • Significantly reduced vibrations for the driver • Provides a more pleasant and smoother ride • Driver fatigue is also greatly reduced, resulting in a significant increase in productivity. Rugged Durability, High Performance, Extreme Environments, Demanding Applications The GTS series is designed to tackle any task placed in its path. Almost maintenance free wet disc brakes (enclosed and oil cooled) ensure the best possible brake...

Open the catalog to page 4

• Neutral start: If the gear lever is not positioned in neutral, the engine will not start. • Tilt lock valve: Prevents the accidental forward tilting of the mast while engine is switched off. • Gas springs with automatic lock: Prevents accidental closure of hood. • Safety valve: Prevents accidental uncontrolled mast lowering in the event of oil pressure hose damage. • Forward and reverse travel is not possible whilst the parking brake is in the on position. Maximum Visibility + Minimum Fatigue Ultimate Safety & Product In

Open the catalog to page 5

GTS20-33 STANDARD FEATURES & BENEFITS HYDRAULIC SYSTEM l Maximum Horsepower • Uses a load-sensing flow control valve for steering to reduce horsepower loss and heat buildup. l Optimum Performance of Attachments • The main hydraulic valve incorporates adjustable flow controls for tilt and auxiliary functions. l Sectional Design • Allows for easy addition of extra functions and simplifies service. l Upright Mounted Load Lowering Valve • Controlled lowering speed independent of load speed. Simple & Reliable • Transmission disengages when parking brake is set preventing driving against brakes....

Open the catalog to page 6

STEERING AXLE • Rugged Design • Linkage pivot pins have a “double shear” design to withstand impact without loosening or breaking. • Solid push rods guarantee trouble-free applications even under tough conditions. RUGGED UPRIGHT AND CARRIAGE • I-Channel Construction • Maximizes visibility and stability, allows for internal hosing and wiring. • Six carriage rollers and two side-thrust rollers minimize deflection and sideplay, reduce roller contact stress and extend component life. • Hydraulic cushioning valves provide silent staging of the rails to reduce shock during both lifting and...

Open the catalog to page 7

Note: “Photos and illustrations are based on information at time of printing and are subject to change without notice. Some products may be shown with optional equipment. Model assumption detail variations are possible.” CLARK EUROPE GmbH Dr.-Alfred-Herrhausen-Allee 33 · 47228 Duisburg / Germany Tel: +49 (0)2065 499 13-0 · Fax: +49 (0)2065 499 13-290 Info-europe@clarkmheu.com · www.clarkmheu.com © 2016 CLARK EUROPE GmbH

Open the catalog to page 8All CLARK Material Handling catalogs and technical brochures

-

CLARK Low Lift Pallet Truck

12 Pages

-

CLARK Full Line

8 Pages

-

CLARK Pallet Stacker

8 Pages

-

Brochure CLARK CRX10 25FL EN

8 Pages

-

Specification sheet SRX14/16

6 Pages

-

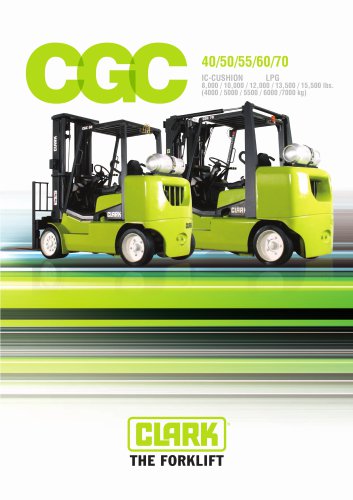

Specification sheet CGC40-70

6 Pages

-

Specification sheet S20-32C

6 Pages

-

Specification sheet C15-20sC

6 Pages

-

Specification sheet GTS20-33

6 Pages

-

Reach truck SRX14/16

8 Pages

-

Electric stacker SX12/16

8 Pages

-

CLARK Full Line

8 Pages

-

SX 12/16

6 Pages

Archived catalogs

-

Specification sheet WPio12

6 Pages

-

WSXD20

8 Pages

-

Brochure CLARK S-Series

8 Pages

-

WPX18

8 Pages

-

WP15

8 Pages

-

WPio12

2 Pages

-

C 15/18/20s(C) GEN2 Series

8 Pages

-

EPX 16/18/20s

5 Pages

-

TMX 13/15s/15/18/20x

7 Pages

-

GEX 40/45/50

8 Pages

-

GEX/GTX 16/18/20s

8 Pages

-

C40-55s

8 Pages

-

WS 10M

8 Pages

-

WS 10

8 Pages

-

WSX 12/14

8 Pages

-

WSXD 20

8 Pages

-

CRT 16/20SE ac

8 Pages

-

CRT 14/16/20 ac

8 Pages

-

SRX 14/16

8 Pages

-

CRT 13/16K ac

8 Pages

-

WS & SX

8 Pages

-

WP & PX

8 Pages

-

PX20

8 Pages

-

C 60/70/75/80 GEN2 Series

8 Pages

-

C 40/45/50/55s Gen2 Series

8 Pages

-

C 25-35/20C-32C Gen2 Series

8 Pages

-

CRX Series

6 Pages

-

CQ 20/25/30

6 Pages

-

CLARK Evolution

2 Pages

-

CTX 40/70

8 Pages

-

GEX 20/25/30(s/L)

8 Pages

-

Electric Reach Truck

8 Pages

-

Electric Power Stacker

8 Pages

-

Electric Pallet Truck

8 Pages

-

CGC 40/70 NON EU

10 Pages

-

C 15C/18C/20Cs GEN2 Series

8 Pages

-

GenEX Series GEX 40/45/50

8 Pages

-

CLARK_FULL-LINE

8 Pages

-

Data sheet CLARK-C40-55s

6 Pages

-

CLARK C60-80

8 Pages

-

Clark C 20-35

16 Pages

-

Clark CMP 50-75

2 Pages

-

Clark CMP 40-50s

2 Pages

-

CLARK CMP15-20

2 Pages

-

CLARK-GTX/GEX16-20s

12 Pages

-

CLARK CQ 20-30

6 Pages

-

Brochure CRX

6 Pages

-

Data sheet CLARK-CMP40-50s

6 Pages

-

Data sheet Clark-CMP50-75s

6 Pages

-

New GEX 20-30

10 Pages

-

Data sheet CLARK-GEN2 C20-35

7 Pages