Website:

Parker Chomerics Division

Website:

Parker Chomerics Division

Group: Parker

Catalog excerpts

aerospace climate control electromechanical ltration uid & gas handling hydraulics pneumatics process control sealing & shielding Conductive Compounds Selector Guide Conductive adhesives, conductive sealants/gap llers, and conductive coatings Chomerics ENGINEERING YOUR SUCCESS.

Open the catalog to page 1

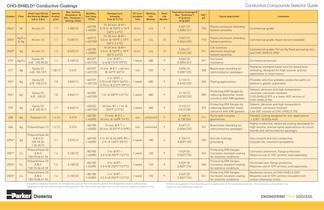

Conductive Compounds Selector Guide CHO-SHIELD® Conductive Coatings Specic Gravity 4 g/mL Max. Surface Resistance 4 @ (Rec. Thickness 3) ohm/sq. (mils) Min/Max. Use Temp. °F(°C) Product Filler Resin Type (Parts) Mix Ratio by Weight A:B or A:B:C 2044* Ni Acrylic (1) 1.2 1.000 (2) -40/185 (-40/85) 2056* Ag/Cu & Ag Acrylic (1) 1.1 0.030 (1) -40/212 (-40/100) Elevated Cure Schedule Time @ °F (°C) 10-20 min. @ RT+ 0.75 hr. @ 150°F ± 10°F (66°C ± 6°C) 10-20 min. @ RT+ 0.5 hr. @ 150°F ± 10°F (66°C ± 6°C) 10-20 min. @ RT+ 0.5 hr. @ 150°F ± 10°F (66°C ± 6°C) 2 hr. @ RT + 4 hr.@ 175°F (79°C) RT Cure...

Open the catalog to page 2

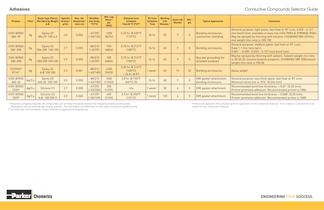

Adhesives Product Conductive Compounds Selector Guide Resin Type (Parts) Mix Ratio by Weight A:B Filler Specic Gravity 4 g/mL Max. Vol. Resistivity 3 ohm-cm Min/Max. Use Temp. °F(°C) Min. Lap Shear 4 psi (kPa) Elevated Cure Schedule Time @ °F (°C)** RT Cure Schedule Time Working Life Minutes 5 Shelf Life Months VOC 2 g/L Typical Application Comments General purpose; light paste; fast heat or RT cure; 0.025 - 0.127 mm bond lines; available in easy mix CHO-PAKs & SYRINGE-PAKs May be sprayed by thinning with toluene. CHOBOND 584-29/toluene weight mix ratio is 100:150 General purpose; medium...

Open the catalog to page 3

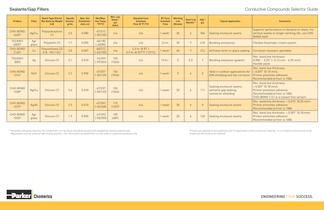

Sealants/Gap Fillers Product CHO-BOND 4660* TECKNIT 0005* CHO-BOND 2165* TECKNIT 0002 CHO-BOND 1016* Conductive Compounds Selector Guide Filler Resin Type (Parts) Mix Ratio by Weight A:B Ag/Cu Polyisobutylene (1) 2.0 0.080 Ag/ glass Polyolen (1) 1.7 0.005 Cu Polyurethane (2) A:B 100:7.021 2.8 0.007 Ag Silicone (1) 3.1 0.010 0.950 Ni/C Silicone (1) Specic Gravity 4 g/mL 2.2 Max. Vol. Resistivity 4 ohm-cm Min/Max. Use Temp. °F(°C) -67/212 (-55/100) Min. Lap Shear 4 psi (kPa) Elevated Cure Schedule Time @ °F (°C) RT Cure Schedule Time Shelf Life Months 5 VOC 2 g/L Typical Application 30 6 306...

Open the catalog to page 4

Conductive Compounds Selector Guide Conductive Coatings - Ordering Information Adhesives - Ordering Information Product Weight (grams) Packaging Chomerics Part No. Primer Included Weight (grams) Packaging Chomerics Part No. Primer Included CHO-SHIELD 2044 3920 1 gallon aluminum can 52-03-2044-0000 Not Required 1 2 component, premeasured CHO-PAK 50-10-0584-0029 Not Required CHO-SHIELD 2056 4050 1 gallon aluminum can 52-03-2056-0000 Not Required 2.5 2 component, premeasured CHO-PAK 50-02-0584-0029 Not Required CHO-SHIELD 2040 4238 1 gallon aluminum can 52-03-2040-0000 Not Required 3 2...

Open the catalog to page 5

Conductive Compounds Selector Guide Sealants/Gap Fillers - Ordering Information Product CHO-BOND 4660 CHO-BOND 4669 TECKNIT 0005 Primer - Ordering Information Weight (grams) Packaging Chomerics Part No. Primer Included Product Weight (grams) Packaging Chomerics Part No. 113.4 4 uid ounce aluminum foil tube 51-02-4660-0000 Not Required CHO-BOND 1085 400 1 pint can 50-01-1085-0000 681 0.1 gallon ber cartridge 51-05-4660-0000 Not Required 10 3 dram glass vial 50-10-1086-0000 113.4 4 uid ounce aluminum foil tube 51-02-4669-0000 Not Required 95 4 uid ounce glass bottle 50-04-1086-0000 681 0.1...

Open the catalog to page 6

NOTES: 1. 2. 3. 4. 5. Material is sufciently cured after 24 hours for handling purposes. Full specication properties are developed after time given. Volatile Organic Content (VOC) values are theoretical approximations calculated from the characteristics of the components in the product as we know them at this time. The recommended thickness may vary from application to application. Please ue the published data as an initial guideline. Contact Chomerics’ Application Engineering for assistance. Properties listed are for products prepared at the elevated cure schedule. Test Methods: Specic...

Open the catalog to page 7All Parker Chomerics Division catalogs and technical brochures

-

SPRINGMESH™

5 Pages

-

MESH STRIP®

6 Pages

-

POLA® SOLID

4 Pages

-

METALASTIC EXP-URE

2 Pages

-

POLA-H® Composite Gasketing

1 Pages

-

Catalogue

33 Pages