Website:

CG Power Systems

Website:

CG Power Systems

Group: Crompton Greaves

Catalog excerpts

Presentation of the Pauwels Group Construction of a distribution transformer the ferromagnetic core 6 the windings 10 the active part 12 the tank 14 finishing operations and testing 18 A comprehensive product range Economic choice of transformers Transformers and the environment low-noise transformers 25 leakproof tanks and environmentally sound coolants 26 recyclable materials 26 radical exclusion of PCBs 27 electromagnetic compatibility 27 optimized use of raw materials 27 lower consumption of primary energy sources, due to the use of transformers with low losses 27 Design, specifications...

Open the catalog to page 2

The Pauwels Group is one of the world’s leading transformer manufacturers. Group companies operate manufacturing plants and sales offices in three continents, with a worldwide network of sales agents and customers in over 135 countries. 5 From its base in Mechelen, Belgium, Pauwels International N.V. acts as the overall holding company, defining the Group’s corporate strategy and coordinating the marketing of its entire product range. The Pauwels Group is a full-line supplier, offering a wide range of transformers consisting of: liquid-filled distribution transformers (15 kVA to 10,000...

Open the catalog to page 3

The reactive power dissipation can be lowered by limiting flux disturbances and minimizing air gaps in the joints between the core legs and the yokes. This is achieved by overlapping the core sheets while stacking them (see page 9 under “Cutting and stacking of the core sheets”). Material The core is constructed using thin sheets of cold-rolled grain-oriented magnetic silicon steel insulated on both sides. Conventional grainoriented steel (CGO steel) is used for transformers with normal no-load loss characteristics, while transformers with reduced no-load losses are built using...

Open the catalog to page 4

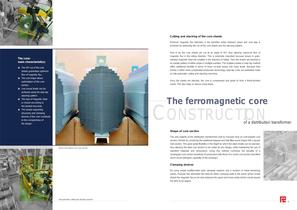

9 Shape of core section The vast majority of the distribution transformers built by Pauwels have an oval-shaped core section, formed by combining the traditional stepped and fully filled round shape with a square mid-section. This gives great flexibility in the height to which the steel sheets can be stacked, thus allowing the ideal core section to be made for any design, while maintaining the use of standard materials and dimensions. Using this method combines the benefits of a rectangular core section (simplicity of production) with those of a round core section (excellent short-circuit...

Open the catalog to page 5

High voltage windings High voltage windings are almost exclusively of layered construction. The copper or aluminium conductors are made of one or more round or square wires, either with an insulating enamel coating or wrapped in insulating paper. Each design is drawn up in accordance with the specific characteristics of the conductor material to be used. The insulation between the layers consists of pre-coated kraft paper, applied either in sheet form or wound in a continuous narrow strip, a technique which allows optimum adjustment of the insulation thickness to the electrical gradient at...

Open the catalog to page 6

13 Bushings are mounted on the cover, which is then fixed onto the assembled active part. The next step consists of connecting the windings to the bushings. The connection methods are durable and selected so as to ensure a solid, low-resistance connection between the linked conducting materials, including junctions between aluminium and copper components. Transformers are often fitted with an off-circuit tap changer. This switch allows the increase or decrease of a certain number of turns while the transformer is disconnected from the circuit. Small variations in the nominal supply voltage...

Open the catalog to page 7

15 The reliability of hermetically sealed tanks is illustrated not merely by the tens of thousands of transformers currently operating worldwide, but also by the stringent fatigue and overpressure tests carried out on transformers of this type. Hermetically sealed tanks have been subjected to 11,000 expansion-contraction cycles, which simulate the mechanical load on a tank over a service life of 30 years (at an average of 1 cycle per day). The construction of these tanks is extremely simple. The bottom, top frame, corrugated fin wall panels and plain wall panels are mounted on specially...

Open the catalog to page 8

Standard tanks are equipped with: securing lugs on the top frame of the tank to secure the transformer during transport lifting lugs on the cover to lift the complete transformer and/or the active part underbase welded to the bottom of the tank with bi-directional rollers (roller base) filling hole on the cover (can also be used to mount an overpressure valve) earthing terminals on tank cover and underbase or tank bottom thermometer pocket welded to the tank cover and filled with cooling liquid drain valve at the bottom of the tank (can also be used to take oil samples) This standard...

Open the catalog to page 9

18 19 Mounting the active part in the tank Once the active part has been dried in the forced air oven, it is given a final comprehensive quality inspection and placed into the tank. The top cover is then either bolted or welded onto the tank, as specified by the customer. Both sealing methods are equally effective, although welding the cover makes it easier to guarantee the seal is leakproof. Filling The transformers are placed in a vacuum chamber and filled with pre-treated liquid (filtered, dried and degassed) under deep vacuum. This ensures optimum impregnation of the insulation...

Open the catalog to page 10

In addition to standard transformer types for distribution applications, Pauwels also builds special transformers for industrial applications. These non-standard types are the result of extensive product development based on constant monitoring and evaluation of changing customer needs in the various market segments. In some cases, special customer requirements have also led to the development of a new product with its own characteristics. Our special distribution transformers have special mechanical and/or electrical characteristics. In the majority of cases, these particular transformer...

Open the catalog to page 11

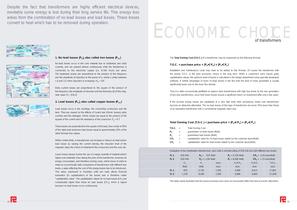

Total Owning Cost (T.O.C.) = purchase price + (P0*CP0) + (Pk*CPk) T.O.C. = Total Owning Cost P0 = guaranteed no-load losses (Watt) Pk = guaranteed load losses (Watt) CP0 = capitalization value for no-load losses stated by the customer (euro/Watt) CPk = capitalization value for load losses stated by the customer (euro/Watt) Evaluation of two distribution transformers, each with a nominal rating of 630 kVA but with different loss levels: Tr. 1 630 kVA P0 = 870 Watt Pk = 5,750 Watt CP0 = 4.25 euro/Watt Tr. 2 630 kVA P0 = 1,150 Watt Pk = 8,400 Watt CPk = 1.15 euro/Watt P0 Pk price P0*CP0 Pk*CPk...

Open the catalog to page 12All CG Power Systems catalogs and technical brochures

-

CG PRESSURE BOOSTING SYSTEMS

24 Pages

-

DC Motors

10 Pages

-

DOUBLE CAGE MOTORS

2 Pages

-

RAILWAY COACH APPLICATION

4 Pages

-

CAPACITOR SWITCH

4 Pages

-

AC drives

8 Pages

-

STAMPING

9 Pages

-

VACUUM CONTACTOR

4 Pages

-

ROTATING ELECTRIC MACHINES

3 Pages

-

AC Generators

11 Pages

-

CG Power Systems

6 Pages

-

Power Transformers

14 Pages

-

Synchronous generators

24 Pages

Archived catalogs

-

switch gear

2 Pages

-

T&D System

2 Pages

-

power transformer

2 Pages

-

distribution transformer

19 Pages