Website:

CEDRAT TECHNOLOGIES

Website:

CEDRAT TECHNOLOGIES

Catalog excerpts

Magnetostrictive Stress Sensor >> Principle Any ferromagnetic material is able to be subjected to magnetostriction. It means that there is a coupling between the mechanical and magnetic states of the material. Because of the “direct magnetostrictive effect”, the material displays a mechanical anisotropic deformation when it is put under a magnetic field. Conversely, the magnetic permeability of such a material changes as a function of the applied mechanical stress. This is called the “inverse magnetostrictive” effect. Therefore, under appropriate magnetic conditions, a measurement of the material’s magnetic permeability gives an indication of its internal mechanical stress state. Finally, the material’s permeability can be measured indirectly by using a coil placed next or around the material (Fig. 1) Figure 1: Principle of a sensor using magnetostrictive effect. (1) Ferromagnetic material, (2) Magnetising coil to reach the operating point on the B(H) curve of the material, (3) Measurement coil to obtain the impedance of the material (4) Magnetic circuit. A sensor for the measurement of stresses in cables used in cable-stayed bridges has been developped. From the electromagnetic analysis realised with our computer simulation tools such as Flux3D (Fig.2), to testing in laboratory, (Fig. 3 and 4), considering different design steps, we evaluated and adapted the various parameters of the sensor in order to get the best quality of measurement (frequency of measurement, level of magnetic polarisation versus the B(H) characteristic of the considered material, impact of eddy currents, temperature, electromagnetic compatibility of the magnetic circuit,….). Figure 2: Electromagnetic analysis of the sensor with Flux3D. Copyright © CEDRAT TECHNOLOGIES | 06/2016 We built a laboratory test bench to measure the magnetostrictive effect of various materials in order to evaluate if we can use them in such kind of sensor. Figure 3: Design and assembly of the sensor around of the cable. CEDRAT TECHNOLOGIES • 59 Chemin du Vieux Chêne • Inovallée • 38246 MEYLAN Cedex France Figure 4: Test of the sensor in laboratory.

Open the catalog to page 1

copyright © cedrat technologies i 06/2016 www.cedrat-technologies.com | actuator@cedrat-tec.com ^ CEDRAT * TECHNOLOGIES Innovation in Mechatronics > Performances CHARACTERISTICS UNIT Material Diameter of the sample mm Active length of the sample mm Relative variation of indutance % Power supply W MAGNETOSTRICTIVE STRESS SENSOR VALUES > Applications Stress sensor used in applications such as monitoring stresses in bridge and nuclear power plant structure. Stress sensor put into structures such as on the bridge cables so as to prevent any risks of rupture or relaxation....

Open the catalog to page 2All CEDRAT TECHNOLOGIES catalogs and technical brochures

-

DTT35XS-SI-2

3 Pages

-

XY Piezo stages heritage

8 Pages

-

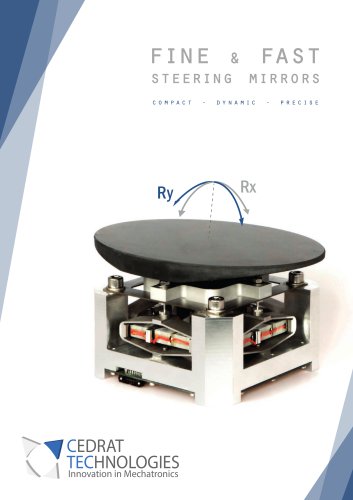

Fine and fast steering mirrors

10 Pages

-

Synchrotron Brochure

10 Pages

-

DTT35XS

3 Pages

-

TT60SM

3 Pages

-

APA600M

2 Pages

-

APA400M

2 Pages

-

APA200M

2 Pages

-

APA150M

2 Pages

-

APA100M

2 Pages

-

APA60SM

2 Pages

-

APA40SM

2 Pages

-

APA60S

2 Pages

-

APA50XS

2 Pages

-

APA35XS

2 Pages

-

APA150XXS

2 Pages

-

APA120S AND CAU10 AMPLIFIER

1 Pages

-

PPA20M

2 Pages

-

PPA40M

2 Pages

-

PPA40L

2 Pages

-

PPA60L

2 Pages

-

PPA80L

2 Pages

-

PPA120L

2 Pages

-

PPA40XL

2 Pages

-

PPA80XL

2 Pages

-

Piezo and magnetic products

77 Pages

-

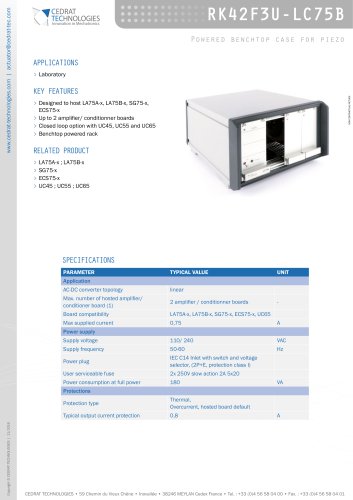

RK42F3U-LC75B

2 Pages

-

CA45

4 Pages

-

LA75A

4 Pages

-

LA75B

4 Pages

-

LA75C

3 Pages

-

SA75A

3 Pages

-

SA75B

3 Pages

-

SA75D

3 Pages

-

SP75A

3 Pages

-

UC65

3 Pages

-

UC55

3 Pages

-

UC45

2 Pages

-

CSA96

3 Pages

-

RK42F3U-LC24

2 Pages

-

ECSU10

2 Pages

-

ECS45

2 Pages

-

ECS75

3 Pages

-

ECP1000

2 Pages

-

ECP500

2 Pages

-

XY25XS

2 Pages

-

APA30uXS

2 Pages

-

PPA10M

2 Pages

-

FP7 SONO PROJECT

2 Pages

-

ASPIC PROJECT

1 Pages

-

viper cleansky project

2 Pages

-

MISAC PROJECT

2 Pages

-

PPSMPAB PROJECT

3 Pages

-

AEROPZT PROJECT

2 Pages

-

DYNXPERTS PROJECT

1 Pages

-

E-LIFT3 PROJECT

1 Pages

-

FluMIn3 projecT

1 Pages

-

CONTACTLESS TORQUE SENSORS

2 Pages

-

MC-SUITE Project

3 Pages

-

addendum

1 Pages