Website:

Carbolite Gero

Website:

Carbolite Gero

Group: VERDER Scientific

Catalog excerpts

Ovens & Furnaces Introduction to Carbolite Ovens & Furnaces Carbolite ovens and furnaces are used in a broad range of industries like Aerospace, Advanced Materials, Chemistry, Coal/Steel, Energy/Electronics, Feedstuffs, Precious Metals, Research and Technical Ceramics. High Temperature Ovens up to 750 °C

Open the catalog to page 1

The Carbolite product range comprises chamber furnaces and ovens from as small as one litre up to 10,000 litres and tube furnaces with heated lengths from as small as 130 mm up to several metres. For 75 years Carbolite products have been the instrument of choice for research, testing and production processes worldwide. Carbolite offers an unmatched level of choice from standard product ranges and accessories or by customisation to meet specic requirements. All Carbolite furnaces are manufactured under an ISO 9001:2008 quality assurance scheme and are designed to comply with the EU Low...

Open the catalog to page 2

AAF 1100 °C Ashing Furnaces The furnaces for optimum ashing conditions and a long working life For deta iled tech nical d p WWW.C lease refer to ata ARBOLIT E.COM/A AF AAF furnaces are suitable for loss on ignition testing or sample preparation for further inorganic analysis. Features 1100 °C maximum operating temperature 3, 7 and 18 litre capacity Designed to comply with BS 1016-104.4:1998, ISO 1171:2010, & ASTM D3174-04: 2010 (3 & 7 Litre models only) Elements are protected from carbon build-up by a hard wearing alumina liner Large oor in the AAF 11/3 and AAF 11/7 and racking system in...

Open the catalog to page 3

Tube Furnaces The Ideal Choice to Heat Small Samples Where sample volumes are quite small or a high degree of uniformity is required, tube furnaces are a good choice. When selecting a tube furnace in addition to the operating temperature other important factors are needed, the heated length and the diameter. Some tube furnaces have the element wound directly on the worktube while other ranges require the addition of a separate worktube unless the sample is to be directly heated in an application such a tensile testing. This type of work is often easier if a split tube design is chosen....

Open the catalog to page 4

CTF 1200 °C Wire Wound Single Zone Furnaces Tube furnaces with larger diameter and longer worktubes For deta iled tech nical p WWW.C lease refer to data ARBOLIT E.COM/C TF12 The CTF series are like the MTF but have larger diameter worktubes for heating samples directly or by using an accessory worktube. This is also required if gas tight or vacuum end seals are to be used. Features 1200 °C maximum operating temperature 65 mm, 75 mm or 100 mm worktube inner diameters 550 mm, 700 mm or 900 mm heated tube length Integral wire wound worktube 301, PID temperature controller with digital set &...

Open the catalog to page 5

Tube Furnaces Accessories, Split Design, Rotation In order to provide optimal conditions for the different test requirements, Carbolite provides a variety of tube furnace options and accessories for heating in air, modied atmosphere and vacuum. These include for example insulation plugs, gas tight end seals, radiation shields and end seals for low and high vacuum applications. Custom made tube furnace equipped with a turbomolecular high vacuum pump End seal and radiation shields for improved uniformity VST 1200 °C Vertical Split Tube Furnaces The free standing vertical design for wrap...

Open the catalog to page 6

High Temperature Ovens A Versatile Range of Laboratory Ovens Ovens are available from 3 litres to 10,000 litres and can be supplied with many load handling options. Maximum operating temperatures range from 250 °C to 750 °C. Temperature control options range from simple and accurate PID set point controllers to sophisticated multiple zone, cascade and programmable, temperature control systems. LHT 400 °C, 500 °C and 600 °C Laboratory High Temperature Ovens Universal bench top ovens with a wide range of optional accessories For deta iled tech nical d ple WWW.C ase refer to ata ARBOLIT...

Open the catalog to page 7

Customised Products For Research & Process Applications Because Carbolite has full control of manufacturing from design to construction and a market leading expertise in heating technology, adding customised modications or producing fully bespoke products is a regular part of the service that we offer to our customers. Some examples are illustrated below. Coke/iron ore reduction test rigs with models suitable for 1, 2 or 3 standard test methods Oven for heating under argon, with multiple exhaust options including condenser and afterburner CF cupellation furnace with side opening door...

Open the catalog to page 8All Carbolite Gero catalogs and technical brochures

-

CAF G5

2 Pages

-

Overview - Ovens & Furnaaces

16 Pages

-

Materialography

20 Pages

-

PF

5 Pages

-

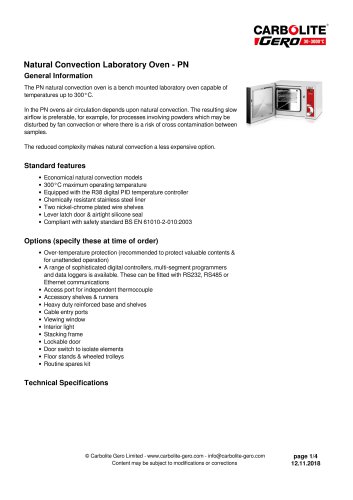

PN

4 Pages

-

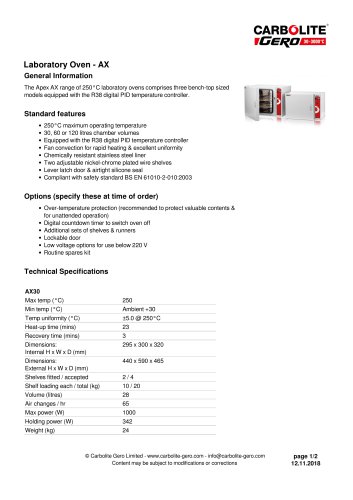

AX

2 Pages

-

Furnaces for Precious Metals

4 Pages

-

Furnaces for Precious Metals

4 Pages

Archived catalogs

-

Verder Scientific Product News

16 Pages

-

LHT

6 Pages

-

RHZS - Rotating Tube Furnace

2 Pages

-

Verder Scientific

20 Pages

-

Furnaces & Ovens for Aerospace

12 Pages

-

Batch Heat Treatment Furnaces

8 Pages