Website:

Carbolite Gero

Website:

Carbolite Gero

Group: VERDER Scientific

Catalog excerpts

Heat Treatment of Metals and Ceramics SOLUTIONS FOR ADDITIVE MANUFACTURING & POWDER INJECTION MOLDING _Powder Metal Laser Sintering (DMLS) _Selective _Stereo

Open the catalog to page 1

CARBOLITE Stress relieving of laser sintered parts with hot wall inert gas retort furnaces APPLICABLE FOR METALS Selective Laser Melting (SLM) Direct Laser Metal Sintering (DMLS) and many others Advantages • Stress relieving of laser printed metal parts • Up to 700°C (HTMA) • Up to 1200°C (GPCMA) • Reactive gas atmosphere > 800°C (hydrogen) • Inert gas atmosphere (argon or nitrogen) • Highest temperature uniformity • Oxygen content can be reduced to 30 ppm • Optional compliance to AMS2750E Nadcap Dimensions: Internal retort H x W x D [mm] For details please refer to our catalogues or...

Open the catalog to page 2

Material Extrusion (FFF/FDM) Stereo Lithography (SLA) Digital Light Processing (DLP) Binder Jetting and many others Debinding and sintering of metal parts Up to 1450 °C (higher available) Inert gas atmosphere (argon or nitrogen) Highest temperature uniformity Reactive gas atmosphere (e.g. 100 % hydrogen for 316L) High vacuum (e.g. turbo pumps for titanium) Remaining binder (backbone binder) removal Dimensions: Internal retort 0 x H [mm] For details please refer to our catalogues or enquire directly www.carbolite-gero.com | Leading Heat Technology

Open the catalog to page 3

CARBOLITE Process development for multiple applications with tube furnaces APPLICABLE FOR METALS & CERAMICS Carbolite Gero HTRV 18/100/500 Stereo Lithography (SLA) Selective Laser Melting (SLM) Digital Light Processing (DLP) Material Extrusion (FFF / FDM) Direct Metal Laser Sintering (DMLS) Binder Jetting and many others Advantages • Debinding and sintering of metal or ceramic parts • Various sizes and temperatures available • Various tube materials available (e.g. quartz glass, mullite, RCA) • Up to 1500°C under vacuum • Up to 1800 °C under inert gas or hydrogen • Very small footprint £...

Open the catalog to page 4

Heat treatment of ceramics with high temperature chamber furnaces APPLICABLE FOR CERAMICS Material Extrusion (FFF / FDM) Stereo Lithography (SLA) Digital Light Processing (DLP) Binder Jetting and many others Advantages • Debinding and sintering of ceramic parts • Works on air • Very small footprint • Up to 1800 on air °C • Highest temperature uniformity • Remaining binder (backbone binder) removal Selection of available high temperature chamber furnaces Model For details please refer to our catalogues or enquire directly

Open the catalog to page 5

Catalytic or thermal debinding with inert gas furnaces CARBOLITE APPLICABLE FOR k METALS & CERAMICS Material Extrusion (FFF / FDM) Stereo Lithography (SLA) Digital Light Processing (DLP) Binder Jetting and many others Advantages • Thermal debinding up to 1100°C (GLO range) • Catalytic debinding up to 150°C (EBO range) • Inert gas control • Safe afterburner combustion • Nitric acid control for catalytic debinding For details please refer to our catalogues or enquire directly Leading Heat Technology | www.carbolite-gero.com

Open the catalog to page 6

Carbolite Gero PF" with moisture extract APPLICABLE FOR METALS & CERAMICS Thermal or Catalytic Binder Feedstock and many others Advantages • Removal of water or organic solvents • 300°C as standard (higher available) • Forced convection for highest uniformity • Works on air • Exhaust fans • Optional compliance to DIN EN 1539 for solvents • Optional compliance to AMS2750E Nadcap For details please refer to our catalogues or enquire directly www.carbolite-gero.com | Leading Heat Technology

Open the catalog to page 7

Particle size and shape analysis, elemental analysis, heat treatment, microstructural analysis and hardness testing: the VERDER SCIENTIFIC companies offer innovative, efficient solutions for your additive manufacturing or powder injection molding process - combined with expert advice and support service worldwide. Machines for cutting, mounting, polishing and etching for surface preparation as prerequisite for reliable microstructural analysis. Particle size and shape characterization by Dynamic Image Analysis. Furnaces for heat treatment, debinding and sintering under air, inert...

Open the catalog to page 8All Carbolite Gero catalogs and technical brochures

-

CAF G5

2 Pages

-

Overview - Ovens & Furnaaces

16 Pages

-

Materialography

20 Pages

-

PF

5 Pages

-

PN

4 Pages

-

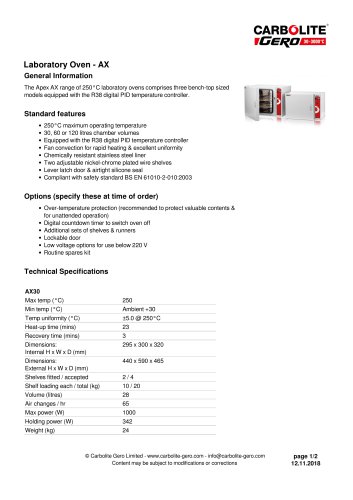

AX

2 Pages

-

Furnaces for Precious Metals

4 Pages

-

Furnaces for Precious Metals

4 Pages

Archived catalogs

-

Verder Scientific Product News

16 Pages

-

LHT

6 Pages

-

RHZS - Rotating Tube Furnace

2 Pages

-

Verder Scientific

20 Pages

-

Furnaces & Ovens for Aerospace

12 Pages

-

Batch Heat Treatment Furnaces

8 Pages