Website:

Carbolite Gero

Website:

Carbolite Gero

Group: VERDER Scientific

Catalog excerpts

Custom Designed Ovens & Furnaces up to 3000 °C LEADING HEAT TECHNOLOGY

Open the catalog to page 1

As part of the VERDER Group, the business division VERDER SCIENTIFIC sets standards in the development, manufacture and sales of laboratory and analytical equipment. The instruments are used in the areas of quality control, research and development for sample preparation and analysis of solids.

Open the catalog to page 2

Leading Heat Technology The Carbolite Gero brand is synonymous with high quality, In addition to the wide range of standard products as leading heat technology in the design and manufacture of shown in this catalogue, Carbolite Gero is an expert in laboratory and industrial ovens and furnaces ranging from the development of customized equipment for complex 30 to 3000 and sold globally to over 100 countries. °C °C heat treatment processes. Solving customers’ individual application requirements has given Carbolite Gero an On 1st January 2016 Carbolite (UK) and Carbolite Gero important place...

Open the catalog to page 3

This catalogue shows the details of some of the custom built design solutions that Carbolite Gero has supplied to many customers to solve their particular heating requirements. Carbolite Gero has a well proven history of adapting its comprehensive range of standard products and also of designing and building complete custom solutions. OVENS – CUSTOM BUILT EXAMPLES About us Common modifications Triple oven system Fan oven with 6 letterbox doors Custom built GP 2/900 chamber oven Content High performance oven with rotating shaft Short form dewar flask oven HPLC column oven with 6 access ports...

Open the catalog to page 4

ROTATING TUBE FURNACES – CUSTOM BUILT EXAMPLES 2 x twin HTR 11/75 rotary reactor tube furnace – total of 4 vessels INTRODUCTION / OVERVIEW OF COMMON MODIFICATIONS TUBE FURNACES – MODIFICATION EXAMPLES AZ – eight-zone tube furnace up to 1300 C ° 4 x GHA 12/450 modular horizontal tube furnaces in a rack system Standard tube furnace HTRH-3 18/100/600 on custom stand with castors 3-zone split 8/300/1500 with rotating and tilting mechanism GVA 12/125/150 modular vertical chamber furnace 3-zone split 13/120/1400 with rotating and tilting mechanism These furnaces are tubular in format. They may...

Open the catalog to page 5

Carbolite Gero can provide custom solutions in one of two ways: 1. Product is a modification of a standard product. 2. Product is custom designed to provide a customer specific process solution. Listed to the right are some common modifications to the standard range of products that are frequently requested. Icons used in this catalogue Icons are displayed against products that feature these details Common modifications for all products • Fans To reduce cooling time and to move ambient air through the hot zone or around the hot zone if an atmosphere is to be maintained (See examples on...

Open the catalog to page 6

CUSTOMIZING CARBOLITE GERO PRODUCTS More common modifications for ovens for vacuum chamber furnaces • Access ports For thermocouple access; for cable entry to parts under test; to give custom shaped access ports for customers’ equipment; ports to quickly load and unload small parts into ovens • Access ports For thermocouple access; ports to quickly load and unload small parts • Access ports Small diameter tube perpendicular to work tube • Special atmosphere with dangerous and reactive gases can be modified to work with H2, CO, CO2, H2S, H2O, CH4 or C2H4 with full safety features. Other...

Open the catalog to page 7

Carbolite Gero’s expertise in pyrometery and the application of AMS2750E Created by the Performance Review Institute, the Nadcap programme is designed to provide an accreditation and quality assurance framework for a defined range of ‘special processes and products’ that are used within the Aerospace and Defence sectors. It was originally sponsored by Boeing and is now adopted by all Western aerospace Loading manufacturers. concept? Nadcap is becoming increasingly important in the aerospace sector with accreditation frequently being requested by companies such as: GE Aviation, Rolls Royce...

Open the catalog to page 8

Product instrumentation ‘Type’ Control instrumentation type is defined as Type A, B, C, D or E. The differences between these types are shown in the diagram below and relate to the number of recording thermocouples permanently installed in the work-space and the instrumentation used to monitor these. Diagram of instrumentation components Type Type Type Type Type A B C D E Control instrument recorder Over-temperature protection instrument Over-temperature protection sensor Multipoint chart recorder (or separate channel in control instrument recorder) High temperature protection sensor...

Open the catalog to page 9

Leading Heat Technology | www.carbolite-ger

Open the catalog to page 10

Examples of custom designed oven solutions Page Page HTMA 6/95 high temperature modified atmosphere oven with continuous sample weighing Ovens – Modification Examples PF 120 fan oven for Nadcap compliance CR/450 clean room oven to fit into a clean room wall LHT 5/60 with sliding tray HRF 7/324 high temperature air recirculation oven with vertically opening door High temperature oven for auto ignition testing Ovens – Custom Built Examples GP 450A general purpose oven for Nadcap compliance High performance oven with rotating shaft GP 450A general purpose oven with rotating mechanism Custom...

Open the catalog to page 11

INTRODUCTION | OVENS FROM 30 °C TO 750 °C Ovens from 30 – 750 °C °C Carbolite Gero defines an oven as a chamber with a metallic lining operating up to 750 °C, where the heat transfer is predominantly by convection. Carbolite Gero’s extensive range of ovens has chamber volumes ranging from 30 to 14000 litres. The following temperature ranges of ovens are available: • Ambient + 30 to 250 °C °C • Ambient + 30 to 300 °C °C • Ambient + 60 to 400 °C °C • Ambient + 60 to 500 °C °C • Ambient + 60 to 600 °C °C • Ambient + 60 to 750 °C °C The majority of Carbolite Gero ovens have...

Open the catalog to page 12All Carbolite Gero catalogs and technical brochures

-

CAF G5

2 Pages

-

Overview - Ovens & Furnaaces

16 Pages

-

Materialography

20 Pages

-

PF

5 Pages

-

PN

4 Pages

-

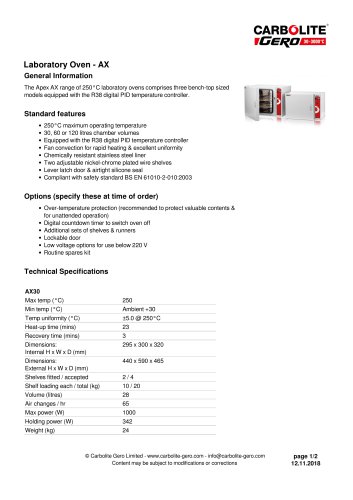

AX

2 Pages

-

Furnaces for Precious Metals

4 Pages

-

Furnaces for Precious Metals

4 Pages

Archived catalogs

-

Verder Scientific Product News

16 Pages

-

LHT

6 Pages

-

RHZS - Rotating Tube Furnace

2 Pages

-

Verder Scientific

20 Pages

-

Furnaces & Ovens for Aerospace

12 Pages

-

Batch Heat Treatment Furnaces

8 Pages