Website:

BETE

Website:

BETE

Catalog excerpts

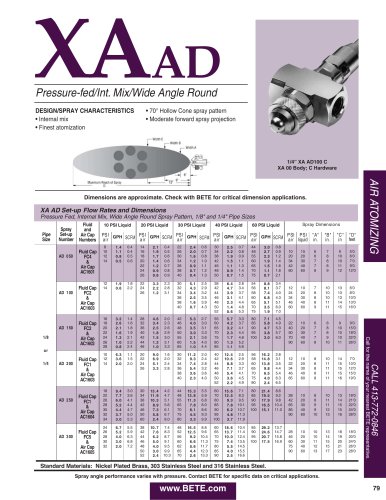

The XA nozzle system uses the energy in compressed air to produce highly atomized sprays at low flow rates. There are many interchangeable components that can be assembled to achieve a variety of spraying objectives. ANNULAR AREA AIR FEED LIQUID FEED External Mix Setups may be used with liquids having a viscosity above 200 centipoise and for abrasive sus pensions. BETE Applications Engineering can provide guidance for spraying high viscosity liquids. TO ORDER: specify pipe size, body style, spray set-up #, hardware and mounting assemblies, and material. See page 74. SPRAY SET-UPS XA nozzles produce eight distinctly different types of sprays, depending AIR CAP FLUID CAP on which interchangeable air and Cutaway View: Internal Mix Set-up fluid caps are selected. The spray type and flow rate are determined by the ”setup”—a specific combination External Mix Set-ups The air and liquid streams exit the of one air cap and one fluid cap. nozzle independently and are com Internal Mix Set-ups bined and mixed outside of the nozzle. Liquid and air streams meet within Because there is no connection between the air and liquid lines within the the nozzle and are mixed together nozzle, the air and liquid flow rates can and expelled through the same ori be controlled independently, allowing fice(s). This internal mixing means precise metering of the liquid. The the streams are not independent; a change in air flow will affect the liq atomization can be controlled by uid flow. This makes precise meter adjusting the air flow rate—more air ing of the liquid more difficult than produces finer atomization. In most with an External Mix Setup. Internal cases these setups do not atomize as Mix Setups are able to produce the finely as Internal Mix Setups. A. End Plug finest atomization of any of the XA setups, but they are generally not suitable for use with liquids which have a viscosity that is above 200 centipoise. LIQUID FEED LIQUID ORIFICE Cutaway View: External Mix Set-up Siphon Set-ups Internal and External Mix Setups require the liquid to be supplied to the nozzle under pressure from a municipal water supply, pump, or pressure vessel. Siphon Setups use the flow of compressed air within the nozzle to siphon liquid from a container. Siphon Setups are frequently used for spraying additives from a container without the use of a pump. They provide the D. Clean-out/Shut-off Bold letters (A, B, C, D, E, F) refer to hardware assemblies shown on

Open the catalog to page 1

BASIC OPERATION D. Cleanout/Shutoff. Combines A. Plug. The minimum option hardware assembly required for XA functions of hardware assemblies B operation. Provides neither cleanout and C in one unit. nor shutoff. B. Shutoff. Turning the knurled knob will stop the flow of liquid to the nozzle. Should not be used to meter the flow of liquid. C. Cleanout. Pressing the spring loaded plunger will force a small diameter rod through the liquid orifice, cleaning any obstruction. Useful for intermittent spraying of a liquid that may dry in the orifice PR Air Cap when not in use. XA00 Body with...

Open the catalog to page 2

XA Components & Options Spray Set-up Hardware Assemblies Body Styles and Seals XA 03 - Spray perpendicular to parallel inlets Front Gasket XA 10/11 Bodies: Low profile Built-in cylinder XA10 – Separate atomizing and cylinder air inlets XA11 – Combined atomizing and cylinder air inlet Seal Kit: 39572 XA 06 (4-5 spray setups) Parallel inlets XA 05 - Spray parallel to parallel inlets Mounting Bracket Bushing Rear Gaskets Large O-rings TO ORDER: specify pipe size, body style, spray set-up #, hardware and mounting assemblies, and material. See page 74. Replaceable Components and Gaskets XA 07 -...

Open the catalog to page 3

XA Components & Options must be used when the air cylinder operates at a different pressure from the atomizing air or where the atomi zing air is supplied below 30 PSI. NOTE: The XA00 Square and XA03 Bodies used for nonautomatic operation can also be used, with hardware assem blies E or F, for automatic operation. Special design features allow field upgrading to automatic operation. The XA10 and XA11 Bodies have a built in airoperated cylinder. The integral cylinder provides a smaller profile for use where space is limited. Hardware Assemblies for Automatic Operation E. AirOperated...

Open the catalog to page 4

TO ORDER: specify pipe size, body style, spray set-up #, hardware and mounting assemblies, and material. See page 74. SPRAY EXTENSIONS The spray setup can be moved away from the nozzle body by using optional 6” or 12” extensions. These allow the spray to be moved closer to the target while keeping the nozzle body and associated piping at a distance. MOUNTING HARDWARE In many XA installations the nozzle is supported by the rigid metal pipe that supplies air or liquid. There are several components which can provide support for the XA Bodies when it isn’t appropriate to suspend the nozzle...

Open the catalog to page 5

XA Components & Options Dimensions are approximate. Check with BETE for critical dimension applications. Dimensions with Hardware Options for XA00 Body, BSP or NPT Spray Set-up Numbers SPRAY SET-UP SIPHON ROUND PRESSURE ROUND WIDE ANGLE ROUND NARROW ANGLE ROUND Dimensions in inches Pipe Hardware Size Overall Dimensions of XA Assemblies with XA00 Body (Shown with E or F Hardware) CENTERLINE FOR AIR & LIQUID INLETS Overall Dimensions for Assemblies with XA01 or XA02 Bodies Overall Dimensions for Assemblies with XA03 Bodies Overall Dimensions for Assemblies with XA05 Bodies Call for the name...

Open the catalog to page 6

TO ORDER: specify pipe size, body style, spray set-up #, hardware and mounting assemblies, and material. See page 74. SYSTEM SET-UPS AND ACCESSORIES BETE carries a complete line of controls and accessories requir ed for setting up a system using the XA Series nozzles. Contact your BETE represent ative for details. Pressure System Set-up In a pressurefed system, the liquid is supplied under pressure to either internal or external mix BETE XA Series nozzles. Air and liquid regulators control the fluid delivery pres sure, while the air filter and liquid strainer ensure that the supplied...

Open the catalog to page 7All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

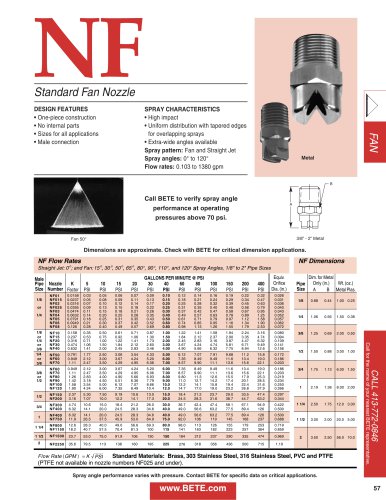

NF

1 Pages

-

SpiralAir

2 Pages

-

TW metric

1 Pages

-

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

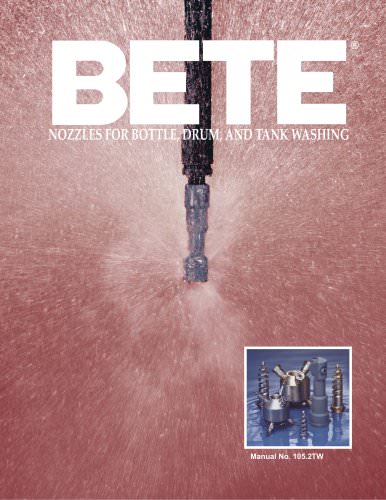

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

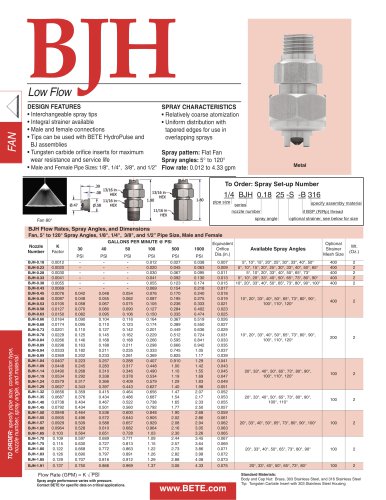

BJH

1 Pages

-

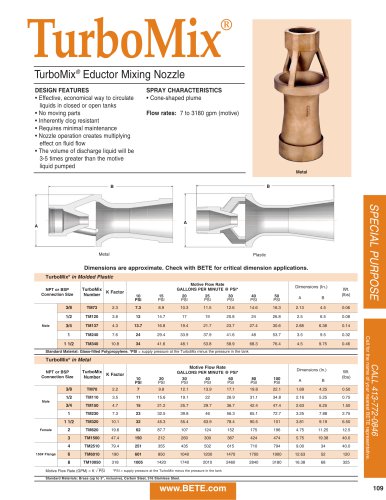

TurboMix

1 Pages

-

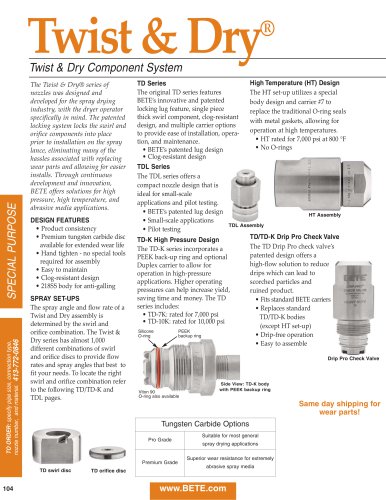

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

p

1 Pages

-

PJ

1 Pages

-

MicroWhirl

1 Pages

-

SPN

1 Pages

-

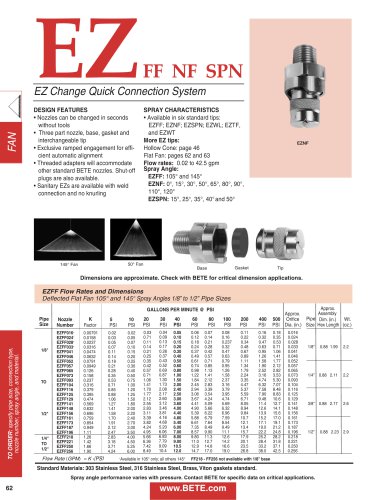

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

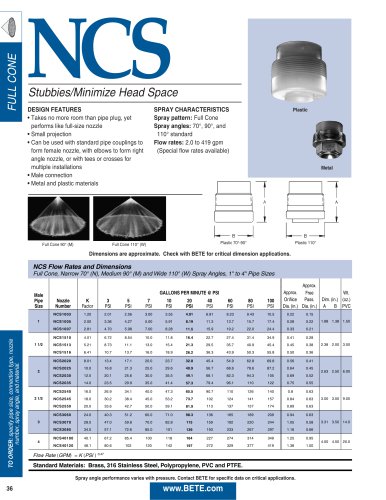

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

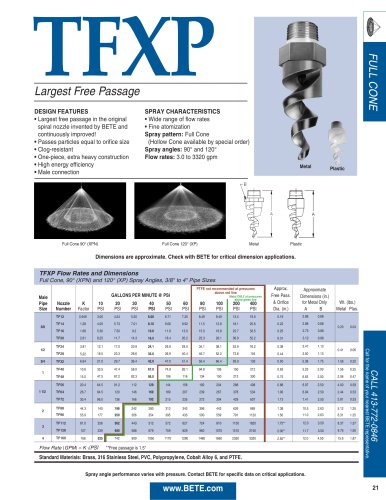

TFXP

1 Pages

-

TF

2 Pages

-

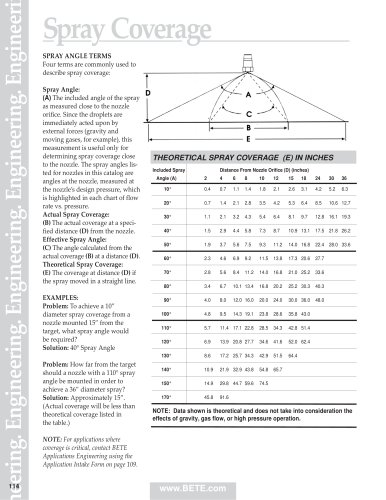

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

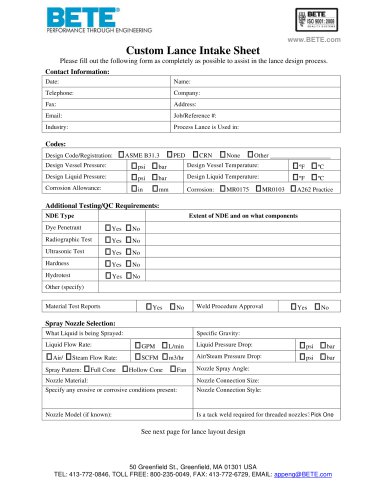

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

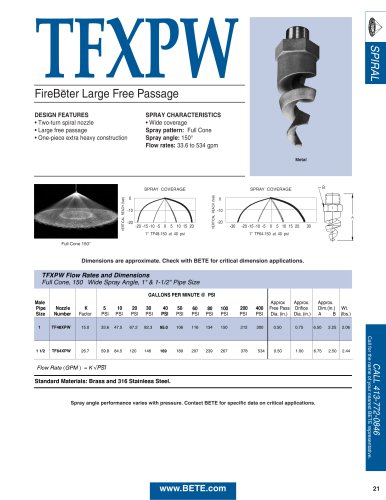

TFXPW

1 Pages

-

N

2 Pages

-

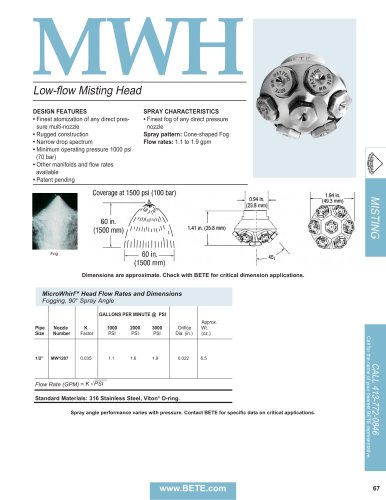

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

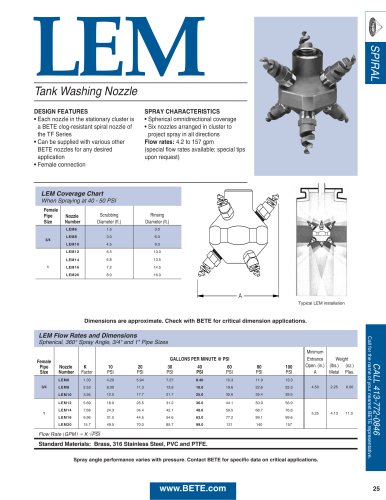

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages