Website:

BETE

Website:

BETE

Catalog excerpts

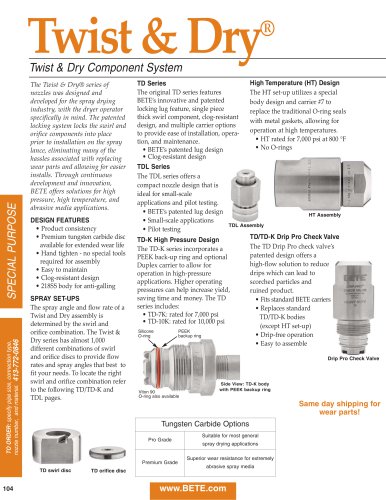

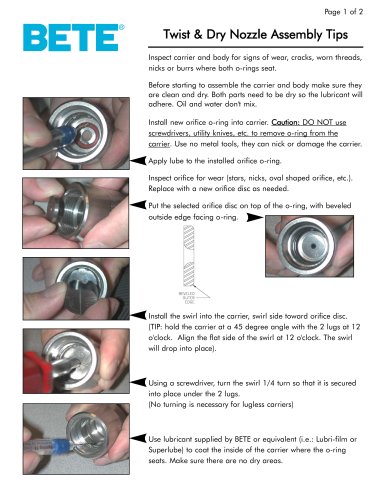

TO ORDER: specify pipe size, connection type, nozzle number, and material. 413-772-0846 SPECIAL PURPOSE Twist & Dry Component System The Twist & Dry® series of nozzles was designed and developed for the spray drying industry, with the dryer operator specifically in mind. The patented locking system locks the swirl and orifice components into place prior to installation on the spray lance, eliminating many of the hassles associated with replacing wear parts and allowing for easier installs. Through continuous development and innovation, BETE offers solutions for high pressure, high temperature, and abrasive media applications. DESIGN FEATURES • Product consistency • Premium tungsten carbide disc available for extended wear life • Hand tighten no special tools required for assembly • Easy to maintain • Clogresistant design • 218SS body for antigalling SPRAY SET-UPS The spray angle and flow rate of a Twist and Dry assembly is determined by the swirl and orifice combination. The Twist & Dry series has almost 1,000 different combinations of swirl and orifice discs to provide flow rates and spray angles that best to fit your needs. To locate the right swirl and orifice combination refer to the following TD/TDK and TDL pages. High Temperature (HT) Design TD Series The original TD series features The HT setup utilizes a special BETE’s innovative and patented body design and carrier #7 to locking lug feature, single piece replace the traditional Oring seals thick swirl component, clogresistant with metal gaskets, allowing for design, and multiple carrier options operation at high temperatures. to provide ease of installation, opera • HT rated for 7,000 psi at 800 °F tion, and maintenance. • No Orings • BETE’s patented lug design • Clogresistant design TDL Series The TDL series offers a compact nozzle design that is ideal for smallscale applications and pilot testing. • BETE’s patented lug design HT Assembly • Smallscale applications TDL Assembly • Pilot testing TD/TD-K Drip Pro Check Valve TD-K High Pressure Design The TD Drip Pro check valve’s The TDK series incorporates a patented design offers a PEEK backup ring and optional highflow solution to reduce Duplex carrier to allow for drips which can lead to operation in highpressure applications. Higher operating scorched particles and pressures can help increase yield, ruined product. saving time and money. The TD • Fits standard BETE carriers series includes: • Replaces standard • TD7K: rated for 7,000 psi TD/TDK bodies • TD10K: rated for 10,000 psi (except HT setup) Silicone PEEK • Dripfree operation O-ring backup ring • Easy to assemble Drip Pro Check Valve Viton 90 O-ring also available Same day shipping for wear parts! Tungsten Carbide Options Pro Grade Premium Grade TD swirl disc Side View: TD-K body with PEEK backup ring Suitable for most general spray drying applications Superi

Open the catalog to page 1

Twist & Dry® Components & Options Talk to one of our engineers; we’re here to help you find the right solution for your application! Durable Beard-Deterring Carrier 1 (CI1 ) (shown) Carrier 11 (CI11 ) - without lug Knife Edge Anti-Bearding Standard Carrier Carrier 2 (CI2 ) (shown) Carrier 5 (CI5 ) - without lug Carrier 10 (CI10 ) (shown) Carrier 12 (CI12 ) - without lug To Order: Spray Set-up Number ¼ TD 2 - 025 - CI1 - 7K – 45 – CVB – B connection type pipe size check valve swirl number omit if no check valve is needed or using HT body CVB for 30 psi (2 bar) cracking pressure CVC for 75...

Open the catalog to page 2

TD/TDK Twist & Dry® Hollow Cone SPECIAL PURPOSE DESIGN FEATURES • Patented locking mechanism for quick and easy change-out and maintenance High pressure applications: • TD-K with PEEK backup ring • HT body with Carrier #7 High temperature applications: • TD/TD-K bodies with silicone O-ring • HT body with Carrier #7 • Female pipe thread or butt-weld connections • Hand tighten, no special tools required • Orifice size: 0.034” through 0.157” • Interchangeable swirl and orifice discs for variable patterns and flow rates • Drip Pro check valve available upon request • Multiple grades of...

Open the catalog to page 3

Twist & Dry/TD-K Flow Rates Hollow Cone; 50° - 85° Spray Angles; 1/4", 3/8", 1/2", and 3/4" Pipe Sizes; NPT, BSP, or Weld Prep Standard Materials: Carrier: Stainless Steel, Duplex; Body: Stainless Steel; Swirl/Orifice: Tungsten Carbide Spray angle performance varies with pressure. Contact BETE for specific data on critical applications.

Open the catalog to page 4

Twist & Dry® Low Flow Hollow Cone DESIGN FEATURES • Patented locking mechanism for quick and easy change-out and maintenance • Lower flow rates than Twist & Dry series Female-threaded or butt weld pipe connections • Orifice size: 0.018” through 0.058” • Interchangeable swirl and orifice discs for variable patterns and flow rates SPRAY CHARACTERISTICS • Hollow Cone Flow rates: 2.86 to 123 gph Spray angle: 70° - 75° Ideal for small-scale applications and pilot tests TDL Assembly SPECIAL PURPOSE Dimensions are approximate. Check with BETE for critical dimension applications. TDL Flow Rates...

Open the catalog to page 5All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

SpiralAir

2 Pages

-

TW metric

1 Pages

-

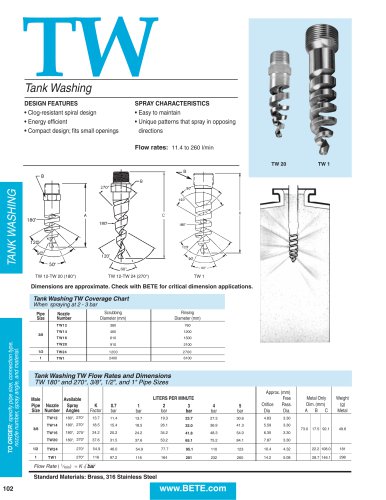

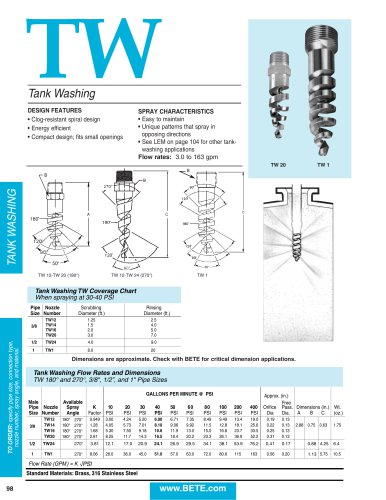

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

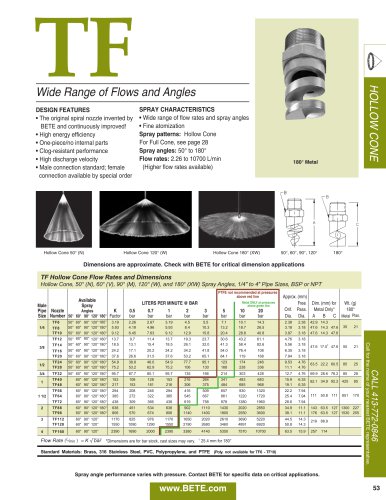

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

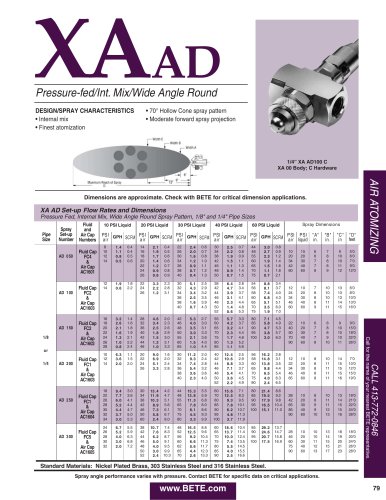

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

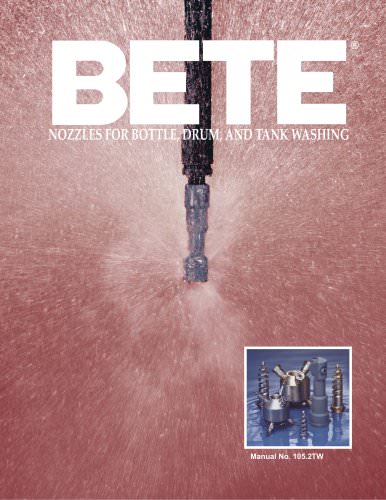

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

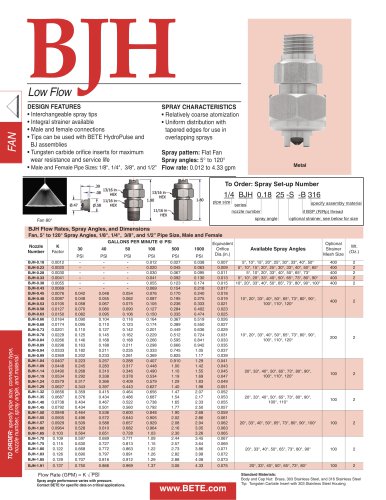

BJH

1 Pages

-

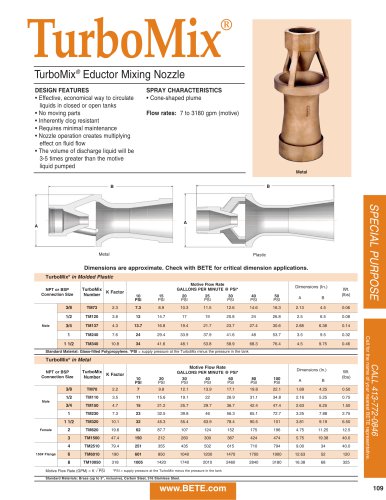

TurboMix

1 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

p

1 Pages

-

PJ

1 Pages

-

MicroWhirl

1 Pages

-

SPN

1 Pages

-

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

TFXP

1 Pages

-

TF

2 Pages

-

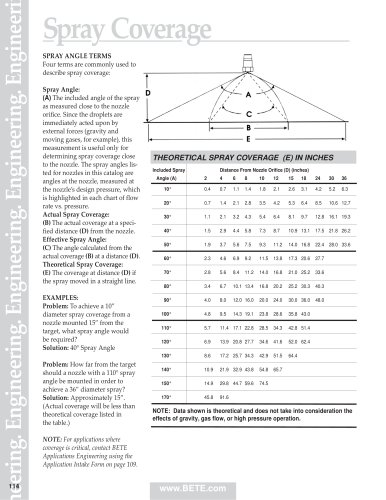

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

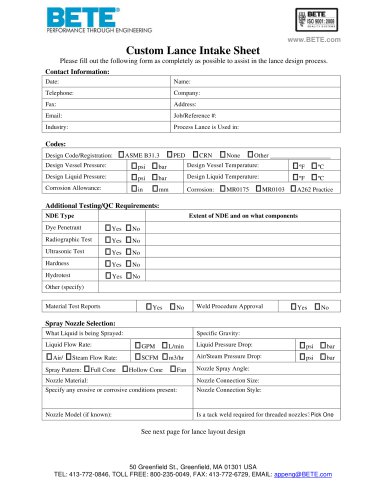

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

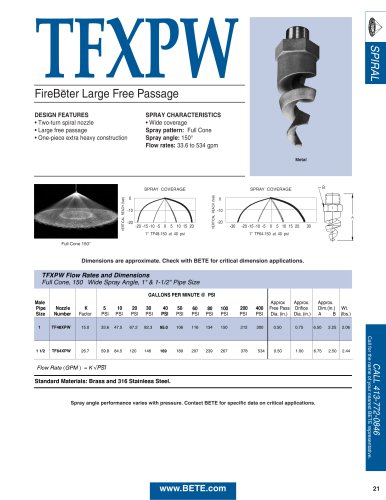

TFXPW

1 Pages

-

N

2 Pages

-

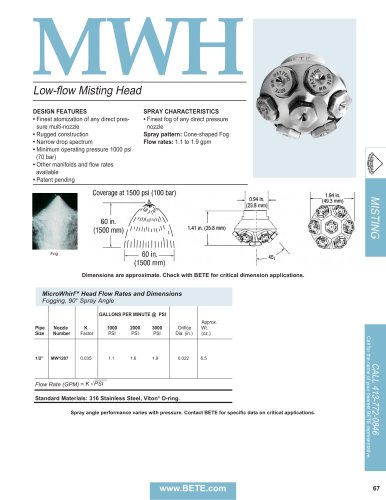

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

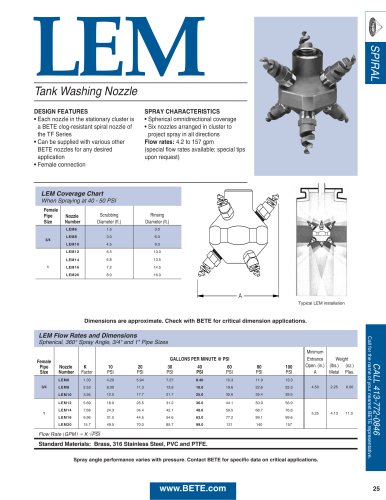

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages