Website:

BETE

Website:

BETE

Catalog excerpts

Choosing the Best Nozzles Let BETE Help You Choose the Best Shower Nozzles and Spray Heads for Your Pulp and Papermaking Processes Experience is the best teacher. Bete Fog Nozzle, Inc. has earned the reputation as the leader in Design Engineering of spray nozzles throughout the Pulp & Papermaking Process Why? Because we take the time and listen. Then we act! BETE has complete in-house Design, Testing, and Manufacturing A. capabilities (including investment Cast Foundry), so turn around time from Design to Installation is controlled. Whether it's a new application or a replacement, BETE is...

Open the catalog to page 2

Pulp Mill and Wood Room Pulp Mill • High impact spray can run • Constructed from one piece with no internals to clog Dust Control • Fine atomization, wide cov- erage for controlling dust at pulp piles and hoppers • Handles stringy lumpy liquids especially well • Premier performer in white water service Washing Mud From Logs, Groundwood Stone Washing • One-piece clog-resistant • Yields higher flow rate pared with the NF series • Highest impact shower with least atomization • Requires different mounting Moistening Logs • Produce wide spray coverage, coarse atomiza- tion with small quantities...

Open the catalog to page 3

Paper Making Headbox, Foam Control, and White Water • Large emitting angles, low flow rates- maximize cover- • Right angle designs with hollow cone patterns for very lumpy white water - greater clog-resistance Broke Chest • Tank, vat washing nozzles • Self-powered rotary nozzle with high impact flat fan tips, covers entire surface washing nozzles. • LEM has spiral high atomiza- tion tips, CLUMP has MP clog-resistant tips Mounts in-line, full cone pattern with slightly greater water requirements Fourdrinier, Cleaning Wires, Felts, Suction and Dandy rolls or PSR straight stream shower • High...

Open the catalog to page 4

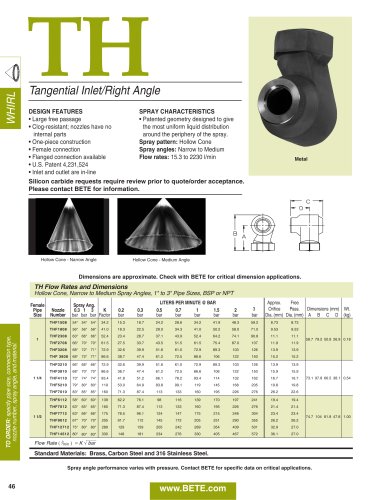

Dry End, Press Section and Converting Press Section MP large free-passage nozzles • Unique, S-shaped vane easily handles lumpy liquid • Full cone, medium flow rate and impact provides excel- lent uniform deluge coverage pipe sizes TH hollow cone nozzle • Vaneless design utilizes less duces a coarser shower • Produce extremely fine Impingement series produce fine mists with low water consumption • Available with siphon, gravity, or pressurized liquid feed changed out without tools - a real boon in tight locations variable spray effects and quick replacement • Available with automatic options...

Open the catalog to page 5

Heat Recovery Cooling Ponds, Odor Control and Water Pollution Heat Recovery of choice for maximizing heat recovery for your mill. • High energy efficiency • Easily handles white water and recirculated water with superior clog-resistance • Large free passage • THW -Wide, even spray band • Right angle design • Flange connection available Cooling Ponds • Greater surface area spray; fine atomization for maximum gas-to-liquid transfer and heat • Excellent Free-Passage • Coarser atomization than TF's • Excellent for lumpy liquids, provides medium atomization Odor Control • Generate extremely fine...

Open the catalog to page 6

Foam Control controlling foam in settling basins, below weirs and spillways moderate-to-high flow rates. • Handles lumpy white water best, TFXP is also a good • High impact and wide spray angle make it excellent for perimeter weir foam control TF, TFXP and MP nozzles provide optimum performance in waste- water aeration in meeting EPA oxygen content requirements • All provide superior clog- • Provide best atomization BETE leading in nozzle design for pollution control and denoxification. Absorber nozzles TF, TFXP, ST.STXP or L nozzles • Produce the best atomiza- Uniformly distributed spray...

Open the catalog to page 7All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

NF

1 Pages

-

SpiralAir

2 Pages

-

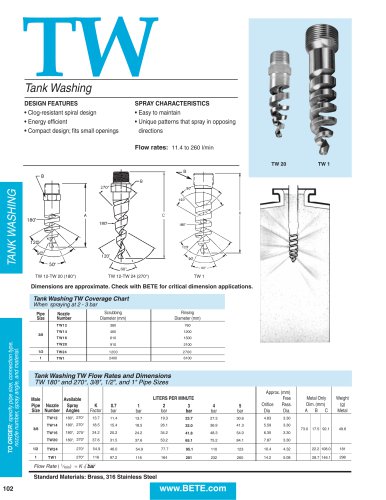

TW metric

1 Pages

-

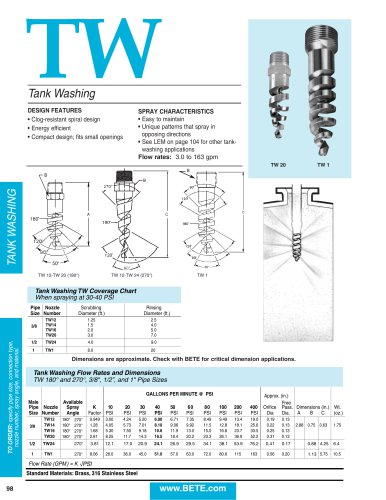

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

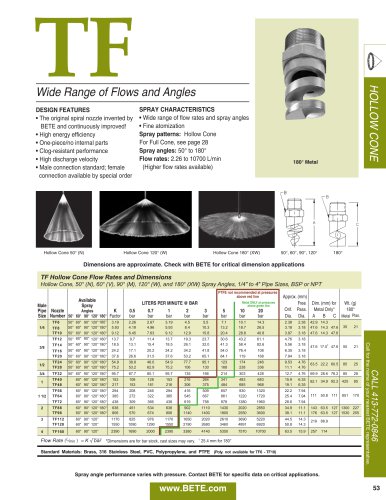

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

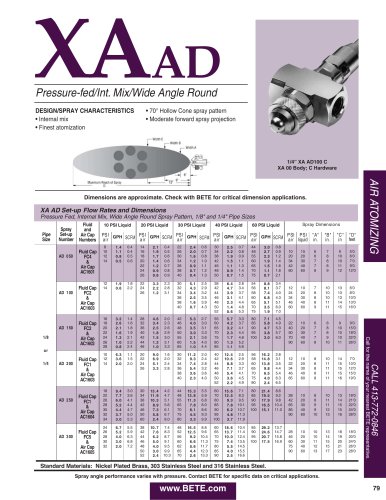

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

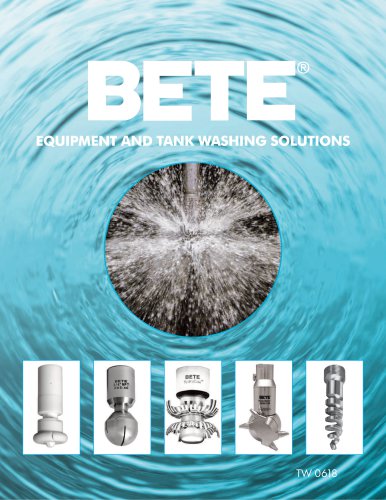

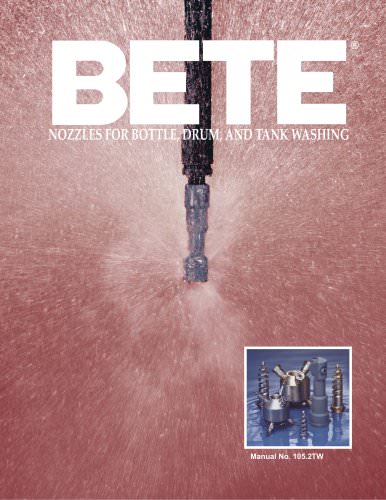

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

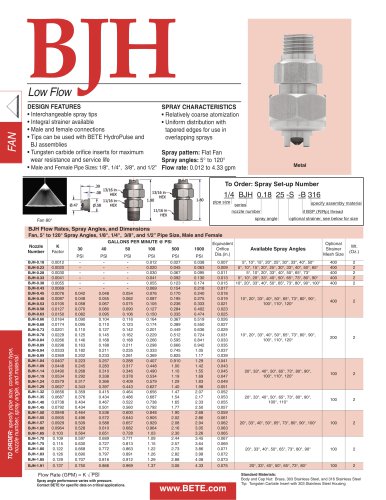

BJH

1 Pages

-

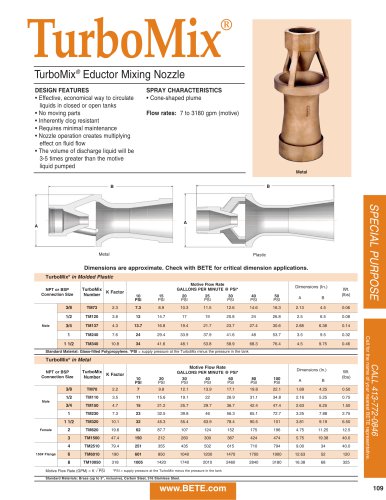

TurboMix

1 Pages

-

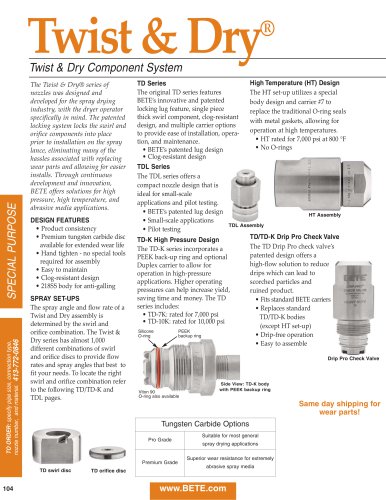

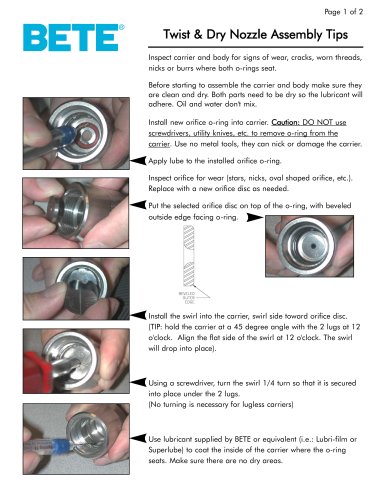

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

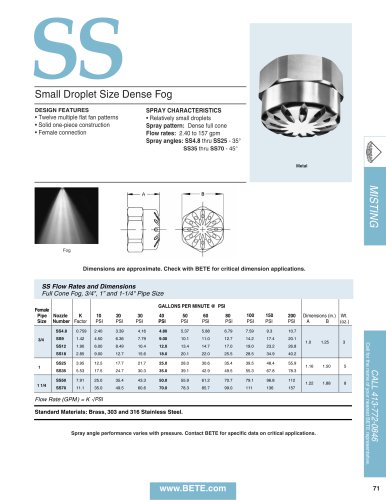

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

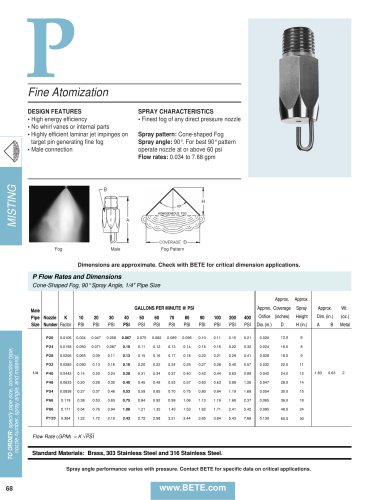

p

1 Pages

-

PJ

1 Pages

-

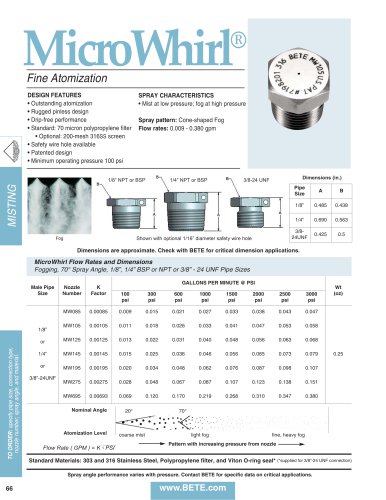

MicroWhirl

1 Pages

-

SPN

1 Pages

-

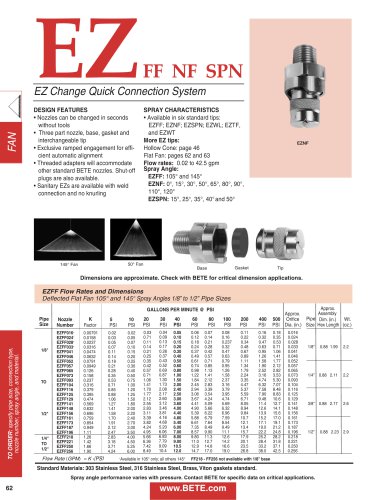

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

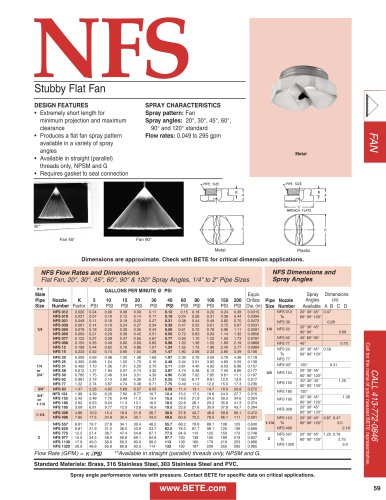

nfs

1 Pages

-

NFD

1 Pages

-

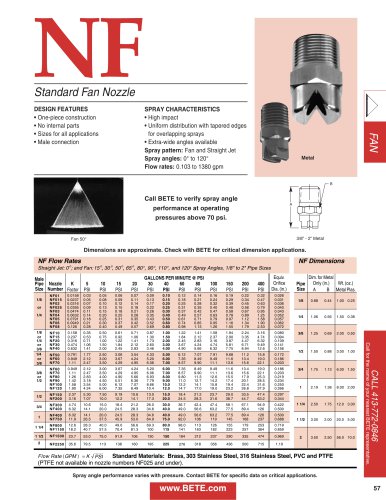

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

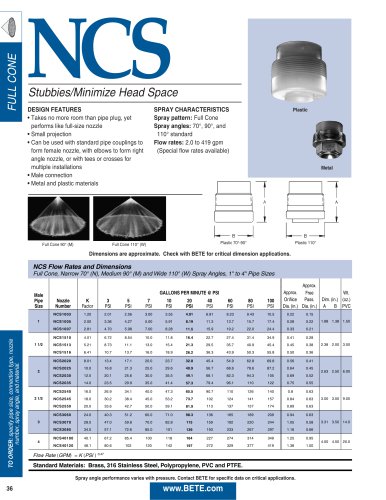

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

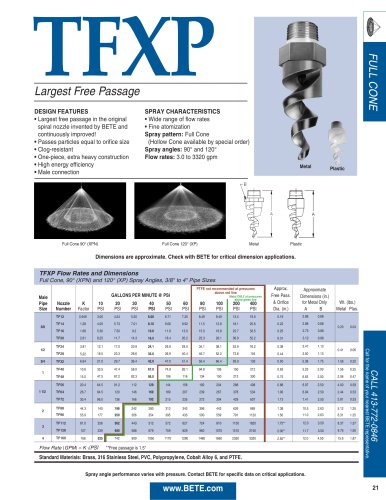

TFXP

1 Pages

-

TF

2 Pages

-

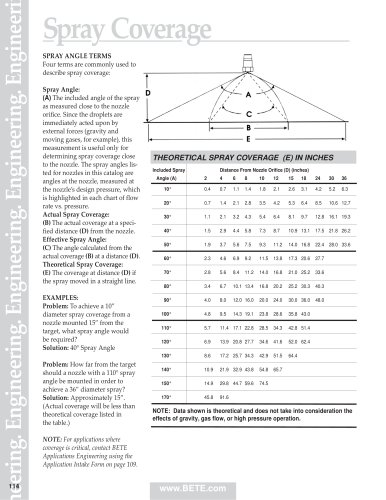

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

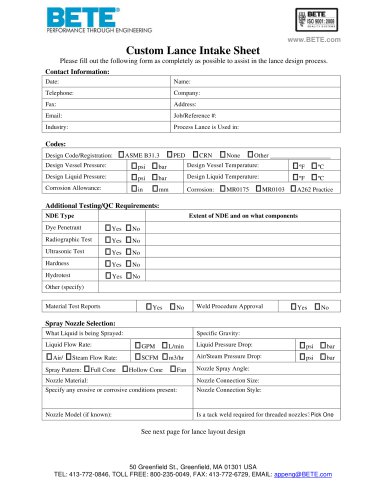

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

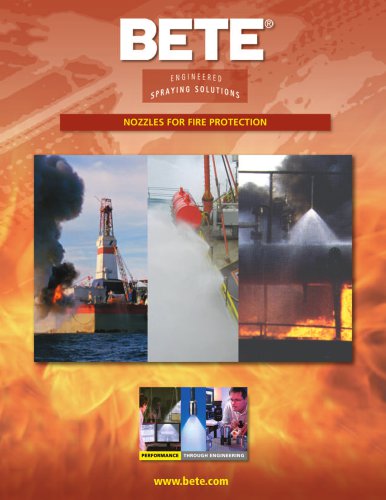

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

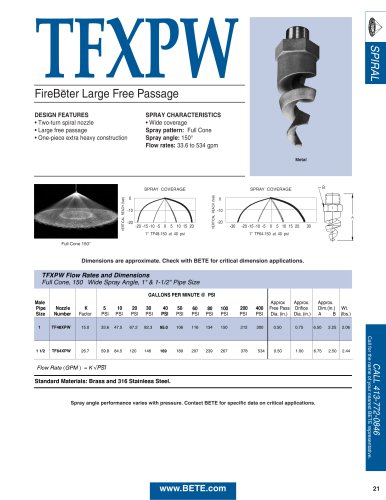

TFXPW

1 Pages

-

N

2 Pages

-

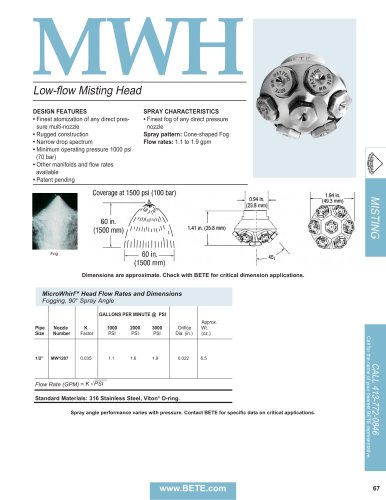

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

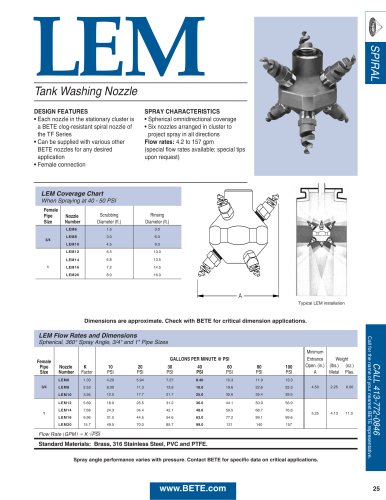

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages