Website:

BETE

Website:

BETE

Catalog excerpts

Fire Protection SPECIAL PURPOSE DESIGN FEATURES • Simplicity of design • One-piece/no internal parts • Clog-resistant • Three standard pipe sizes—1/2”, 1”, and 1-1/2” • Male connection • Factory Mutual, U.S. Coast Guard, and Lloyd's Register approved models SPRAY CHARACTERISTICS • Two spray cones: an outer, wide angle cone and a narrower inner cone combine to give full cone effect Spray pattern: Full Cone Spray angles: 90° and 120° standard Flow rates: 3.0 to 534 gpm Nozzle with optional protective cover Use of blow-off covers requires a pressure of 25 PSI or higher N3-N5W: U.S. Coast Guard approved TF24-150° also available in Factory Mutual approved model (see page 20) N6 nozzles protect a propane storage tank from fire and explosion. Dimensions are approximate. Check with BETE for critical dimension applications. N Flow Rates and Dimensions Full Cone, Medium 90° and Wide 120° (W) Spray Angles, 1/2" to 1 1/2" Pipe Sizes Male Pipe Size GALLONS PER MINUTE @ PSI Nozzle K Number Factor Approx. (in.) Free Orifice Pass. Dia. Dia. TO ORDER: specify pipe size, connection type, nozzle number, and material. Approximate Dimensions Wt. (inches) (oz.) A B Metal Standard Nozzle Materials: Brass and 316 Stainless Steel Available in nickel aluminum bronze and titanium, plus other materials available on request. Standard Cover Materials: Brass for brass nozzles, 304 Stainless Steel for other nozzle materials All N1-N3W nozzles provided with Spray angle performance varies with pressure. Contact BETE for specific data on critical applications. integral strainer. Strainer material: 316SS 0.

Open the catalog to page 1All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

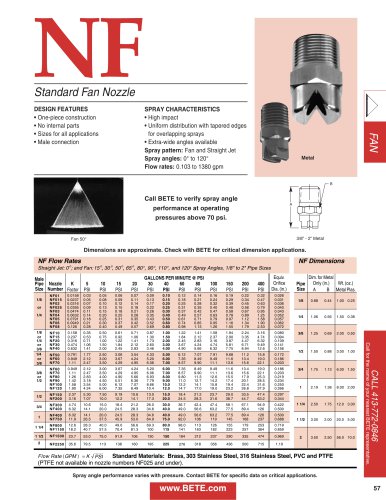

NF

1 Pages

-

SpiralAir

2 Pages

-

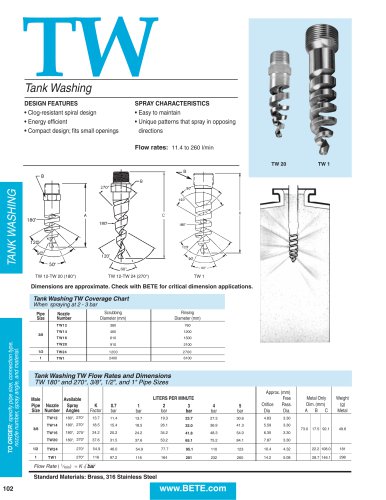

TW metric

1 Pages

-

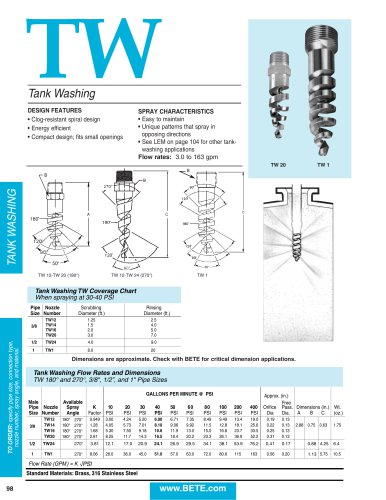

TW

1 Pages

-

AFF metric

1 Pages

-

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

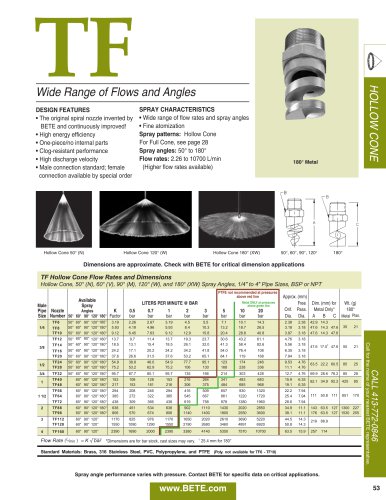

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

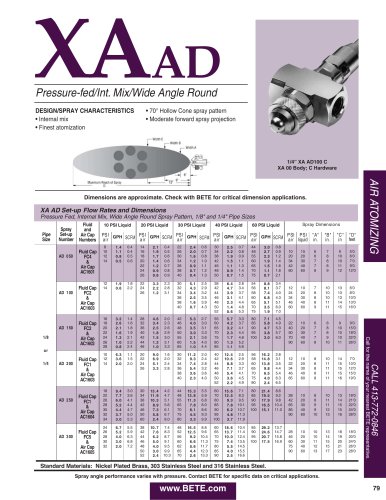

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

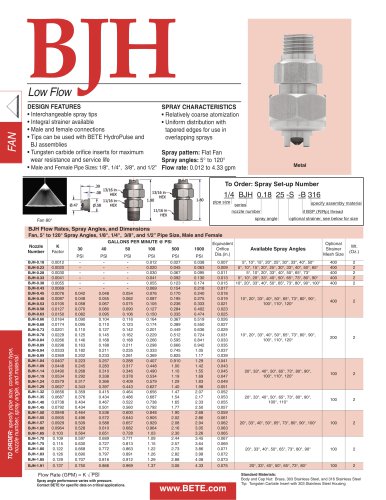

BJH

1 Pages

-

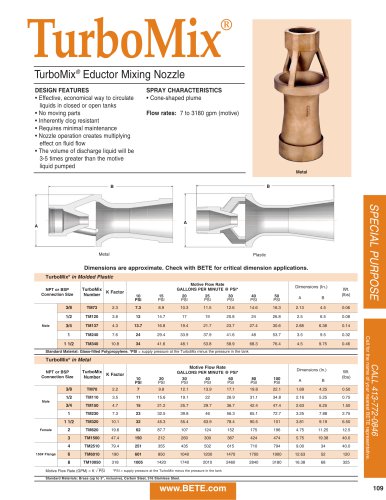

TurboMix

1 Pages

-

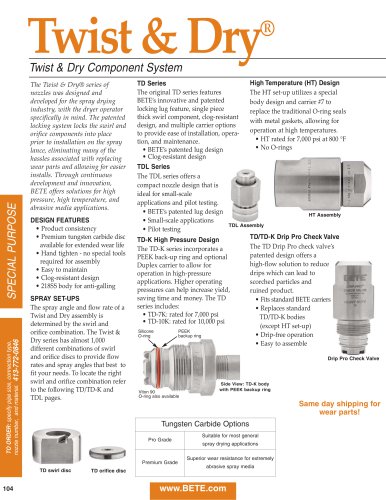

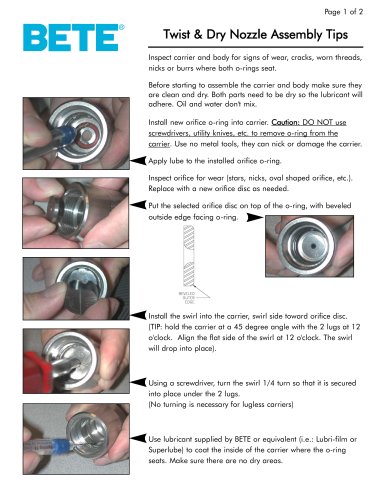

Twist & Dry

5 Pages

-

TF29

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

p

1 Pages

-

PJ

1 Pages

-

MicroWhirl

1 Pages

-

SPN

1 Pages

-

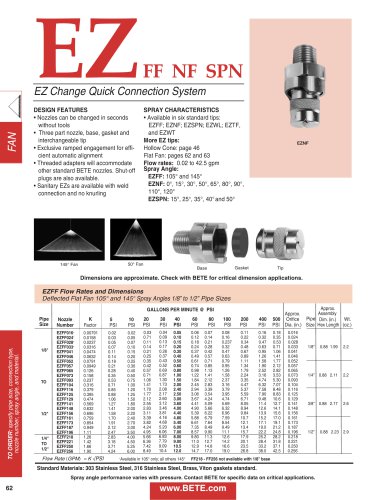

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

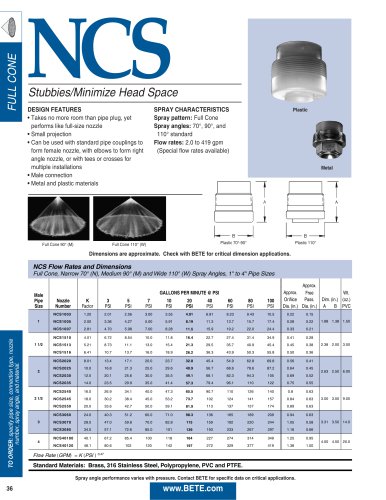

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

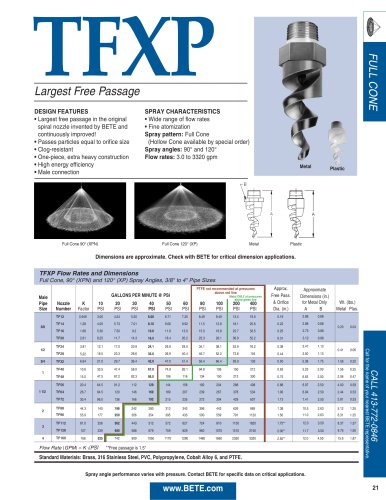

TFXP

1 Pages

-

TF

2 Pages

-

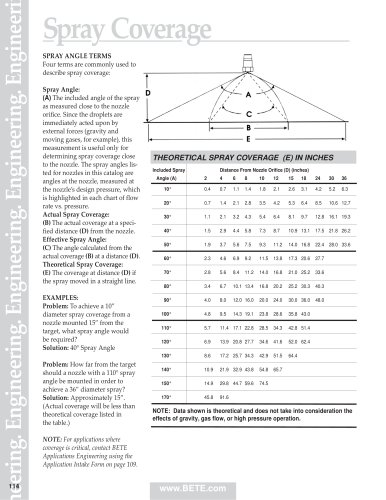

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

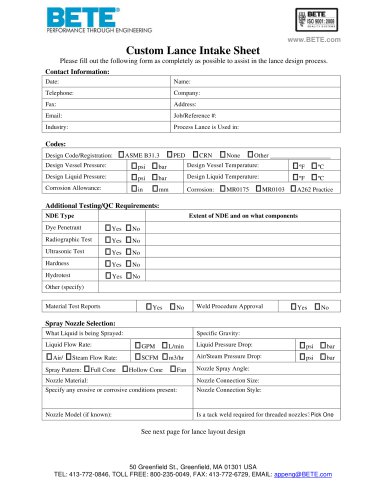

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

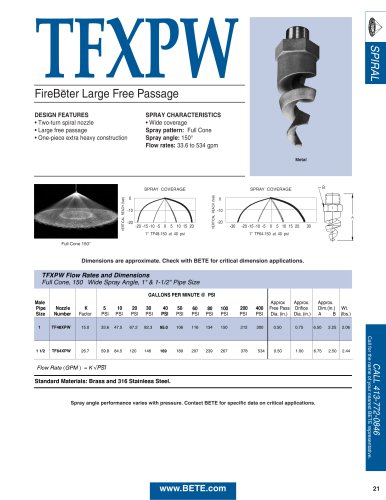

TFXPW

1 Pages

-

N

2 Pages

-

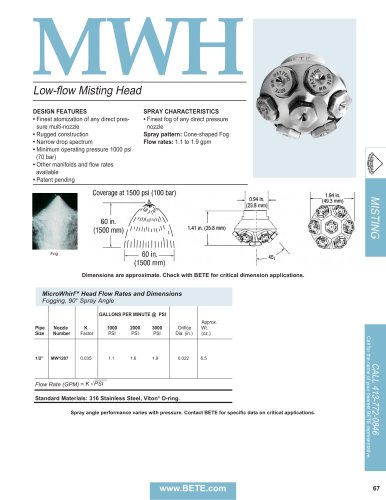

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

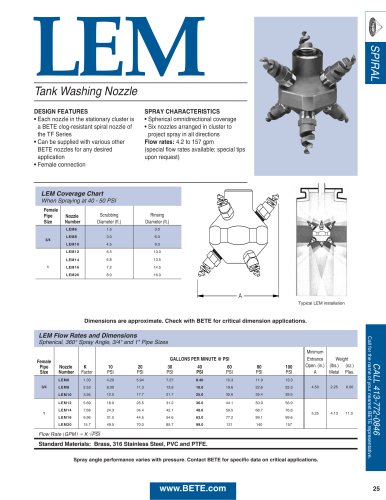

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

N Fire Protection

2 Pages

-

TW

1 Pages

-

Spray dry manual

25 Pages