Website:

BETE

Website:

BETE

Catalog excerpts

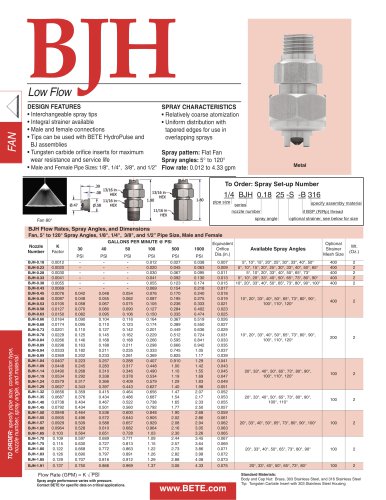

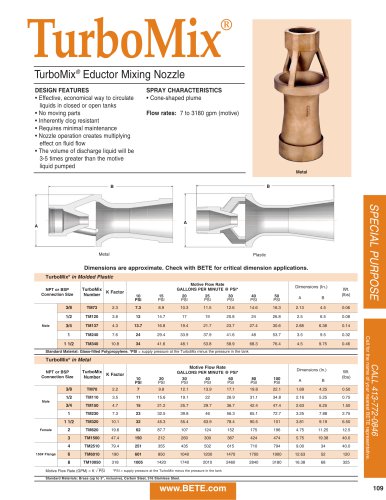

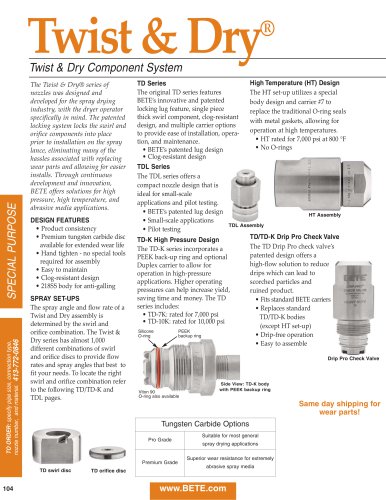

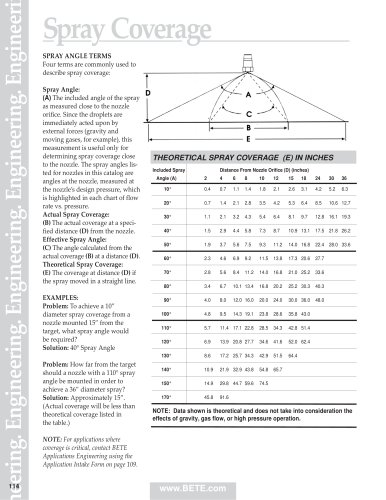

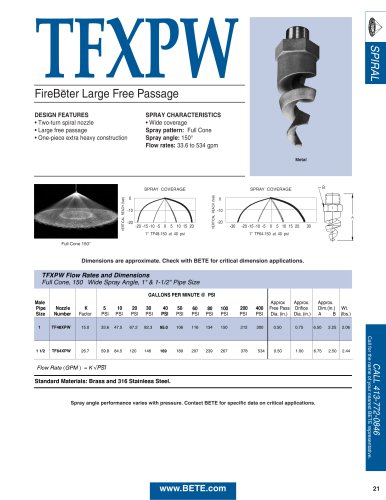

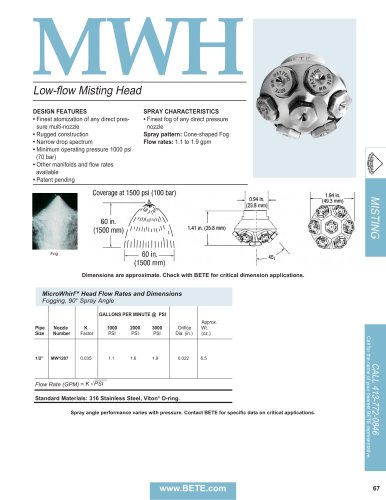

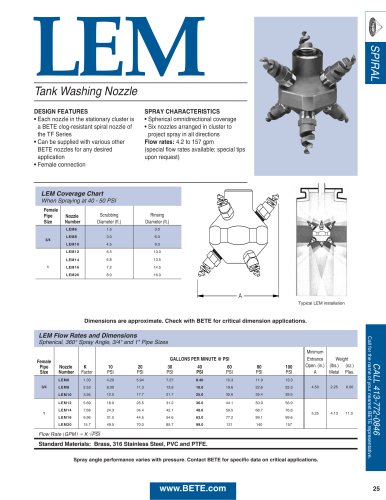

tr.row {} td.cell {} div.block {} div.paragraph {} .font0 { font:4.00pt "Arial", sans-serif; } .font1 { font:4.80pt "Arial", sans-serif; } .font2 { font:5.00pt "Arial", sans-serif; } .font3 { font:5.40pt "Arial", sans-serif; } .font4 { font:6.00pt "Arial", sans-serif; } .font5 { font:7.00pt "Arial", sans-serif; } .font6 { font:7.20pt "Arial", sans-serif; } .font7 { font:8.00pt "Arial", sans-serif; } .font8 { font:9.00pt "Arial", sans-serif; } .font9 { font:10.00pt "Arial", sans-serif; } .font10 { font:10.50pt "Arial", sans-serif; } .font11 { font:12.00pt "Arial", sans-serif; } .font12 { font:13.00pt "Arial", sans-serif; } .font13 { font:16.00pt "Arial", sans-serif; } .font14 { font:9.00pt "Palatino Linotype", serif; } Fire Protection SPRAY CHARACTERISTICS Two spray cones - an outer, wide-angle cone and a narrower, inner cone - combine to give full cone effect Spray pattern: Full Cone Spray angles: 90° and 120° standard Flow rates: 9.67 to 1720 l/min DESIGN FEATURES Օ Simplicity of design One-piece/no internai parts Օ Clog-resistant Three standard pipe sizes1/2", 1", and 1-1/2" Male connection Օ Factory Mutual, U.S. Coast Guard and Lloyd's Register approved models Full Cone 90° Full Cone 120° (W) Dimensions are approximate. Check with BETE for critical dimension applications. N FIow Rates and Dimensions Full Cone, Medium 90° and Wide 120° (W) Spray Angles, 1/2" to 1 1/2" Pipe Sizes, BSP or NPT Approx. (mm) Approximate Male LITERS PER MINUTE @ BAR Free Dimensions Wt. Pipe Nozzle K 0.5 0.7 1 2 3 5 10 20 Orifice Pass. (mm) (g) Size Number Factor bar bar bar bar bar bar bar bar Dia. Dia. A B Metal N1 13.7 9.67 11.4 13.7 19.3 23.7 30.6 43.2 61.1 4.76 3.18 N2 24.2 17.1 20.2 24.2 34.2 41.8 54.0 76.4 108 6.35 3.18 1/2 N3 37.6 26.6 31.5 37.6 53.2 65.1 84.1 119 168 7.94 3.18 63.5 22.4 85 N4 54.9 38.8 46.0 54.9 77.7 95.1 123 174 246 9.53 4.76 N5 75.2 53.2 62.9 75.2 106 130 168 238 336 11.1 4.76 N6 95.7 67.7 80.1 95.7 135 166 214 303 428 12.7 4.76 N6 95.7 67.7 80.1 95.7 135 166 214 303 428 12.7 4.76 1 N7 92.2 35.1 241 153 108 128 153 216 264 341 483 683 15.9 6.35 N8 216 153 181 216 306 375 484 685 968 19.1 6.35 1 1/2 N9 294 208 246 294 416 509 657 930 1320 22.2 7.94 111 50.8 765 N10 385 272 322 385 545 667 861 1220 1720 25.4 7.94 CD 1§ c ,o o CD C c 8 C CD~-2 .Ncg >=J nj cd CDCD9-° UJ .T l8 Flow Rate ( ^min ) = K V bar Standard Materials: Brass and 316 Stainless Steel. Spray angle performance varies with pressure. Contact BETE for specific data on critical applications. 26 www.BETE.com

Open the catalog to page 1

SPIRAL SUPERIOR PERFORMANCECHARACTERISTICS Sprays composed of droplets 30% to 50% smaller than conventional designs at equivalent pressures Օ Extraordinarily large surface area of spray enhances evaporation and cooling Rugged, compact design Օ Multiple concentric cone spray, unique to spiralpattern, maximizes contact SUPERIOR FIRE/LOSS PREVENTIONAPPLICATIONS Gas wellhead protection Օ Safeguarding ship-borne cargo Storage tank protection Օ Secondary explosion protection in explosive,dusty environments Mitigation of HF and other toxic gas releases > N6 nozzles protect a propane storage tank...

Open the catalog to page 2All BETE catalogs and technical brochures

-

WL metric

1 Pages

-

PJ metric

1 Pages

-

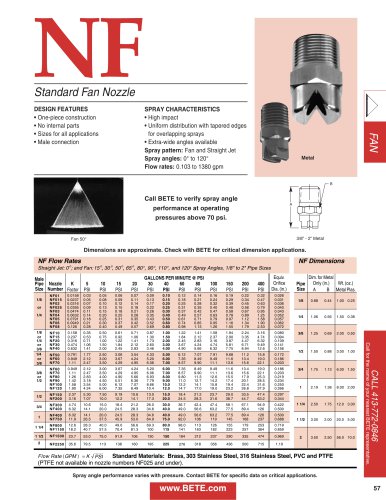

NF

1 Pages

-

SpiralAir

2 Pages

-

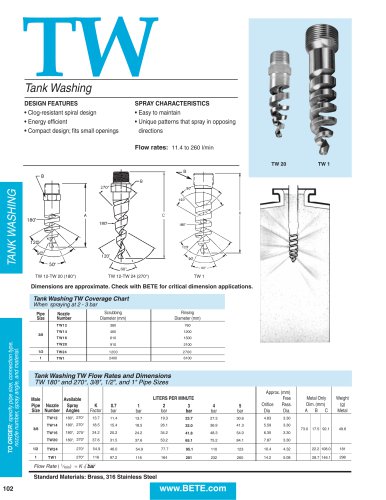

TW metric

1 Pages

-

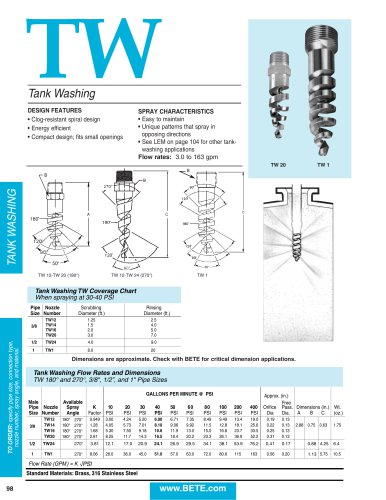

TW

1 Pages

-

AFF metric

1 Pages

-

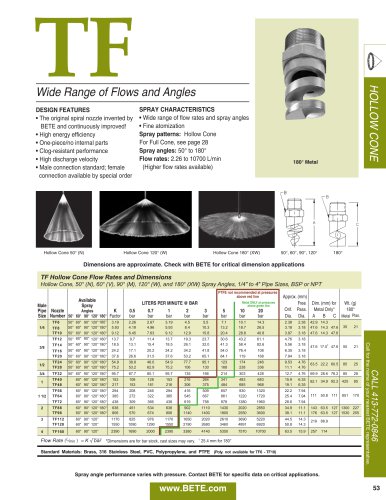

TF10-170

1 Pages

-

TF24

1 Pages

-

TF FM Approved

1 Pages

-

TF metric

1 Pages

-

TF

1 Pages

-

TF

1 Pages

-

MaxiPass®

2 Pages

-

HydroClaw®

2 Pages

-

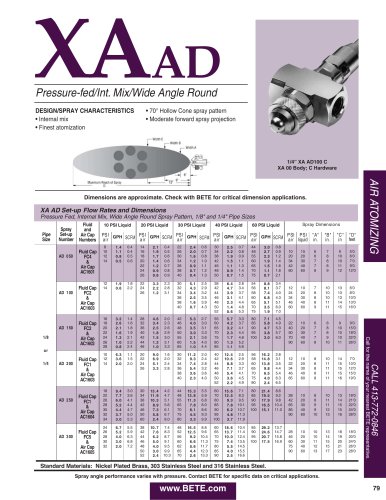

XAAD

1 Pages

-

ST

1 Pages

-

XA Components & Options

1 Pages

-

Engineering Information

9 Pages

-

Custom In-House Fabrications

2 Pages

-

BETE Spray Nozzle Catalog

134 Pages

-

Line Card

2 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

BETE Metric Catalog

132 Pages

-

NFH

1 Pages

-

BJH

1 Pages

-

TurboMix

1 Pages

-

Twist & Dry

5 Pages

-

TF29

1 Pages

-

N fire protection

1 Pages

-

AFF

1 Pages

-

LEM

1 Pages

-

CLUMP

1 Pages

-

HydroWhirl Orbitor

2 Pages

-

HydroWhirl ® Poseidon

1 Pages

-

HydroWhirl S

1 Pages

-

SpiralAir

2 Pages

-

SAM

2 Pages

-

XA Accessories

4 Pages

-

XA

7 Pages

-

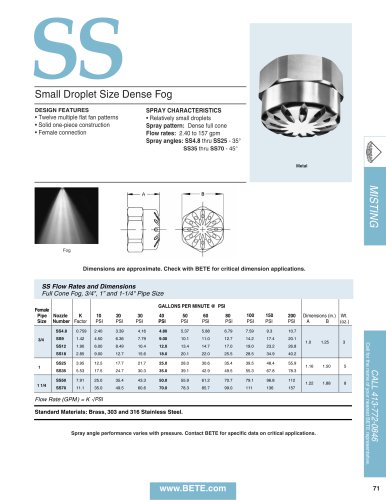

SS

1 Pages

-

UltiMist

1 Pages

-

L

1 Pages

-

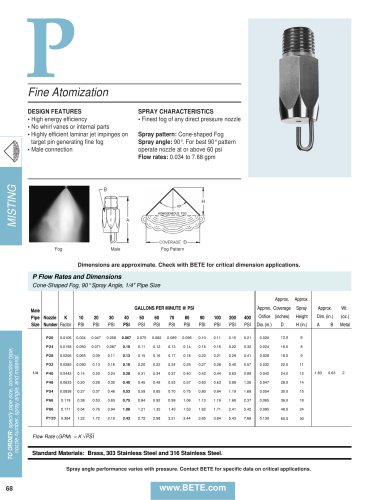

p

1 Pages

-

PJ

1 Pages

-

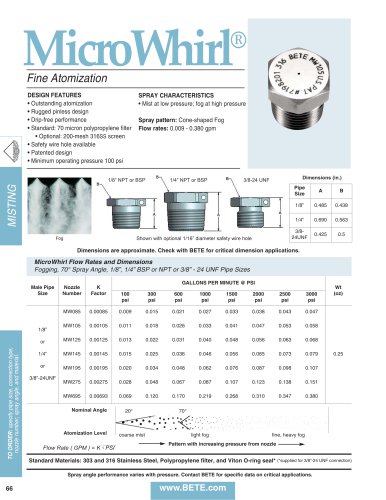

MicroWhirl

1 Pages

-

SPN

1 Pages

-

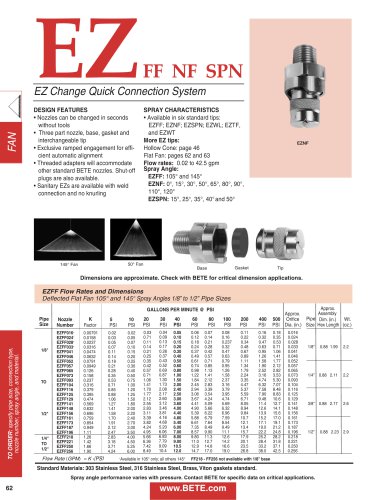

EZ FF NF SPN

2 Pages

-

FF

2 Pages

-

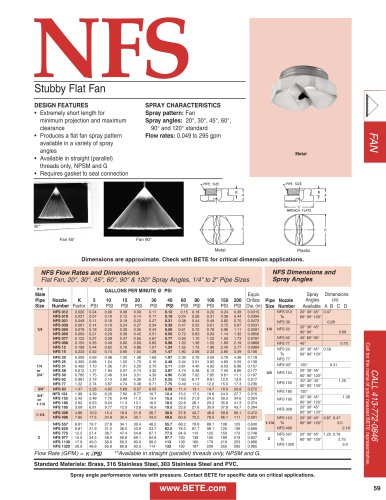

nfs

1 Pages

-

NFD

1 Pages

-

NF

1 Pages

-

NFV

1 Pages

-

HydroPulse

4 Pages

-

BJ

2 Pages

-

Spillback

2 Pages

-

THW

2 Pages

-

NCJ

1 Pages

-

TH

2 Pages

-

WTX

2 Pages

-

WT

2 Pages

-

TC

1 Pages

-

NCFL

1 Pages

-

NCK

1 Pages

-

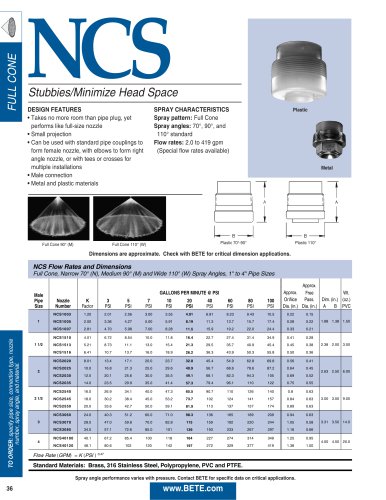

NCS

1 Pages

-

NC

2 Pages

-

SF

3 Pages

-

EZFF

2 Pages

-

WTZ

1 Pages

-

CW

2 Pages

-

WL

1 Pages

-

STXP

1 Pages

-

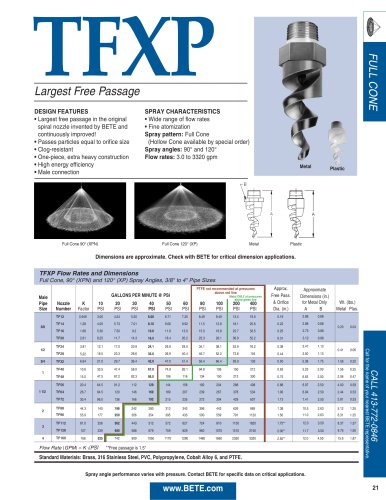

TFXP

1 Pages

-

TF

2 Pages

-

Spray Coverage

1 Pages

-

Bete accessories

1 Pages

-

MATERIALS

1 Pages

-

Custom Lance Intake Sheet

2 Pages

-

Pollution Control

8 Pages

-

Food Industry

8 Pages

-

Fire Protection

8 Pages

-

DUR O LOK®

6 Pages

-

Chemical Processing

8 Pages

-

Spray Nozzle Catalogs

127 Pages

-

MaxiPass ® L

1 Pages

-

TFXPW

1 Pages

-

N

2 Pages

-

MicroWhirlTM Head (MWH)

1 Pages

-

MaxiPassTM Low Flow (MPL)

1 Pages

-

MaxiPassTM (MP)

2 Pages

-

LP

1 Pages

-

LEM

1 Pages

-

IS

1 Pages

-

FluidBed

1 Pages

-

Spray Drying

11 Pages

-

Bottle, Drum & Tank Washing

16 Pages

-

TD/TD-K

4 Pages

-

FINZTM

1 Pages

-

SpiralAirTM

2 Pages

-

SC

2 Pages

Archived catalogs

-

TW

1 Pages

-

Spray dry manual

25 Pages