Website:

ABB Robotics

Website:

ABB Robotics

Group: ABB Automation Technologies

Catalog excerpts

Trace back information: Workspace 23C version a12 Checked in 2023-09-28 Skribenta version 5.5.019

Open the catalog to page 2

Product specification IRB 4600-60/2.05 IRB 4600-45/2.05 IRB 4600-40/2.55 IRB 4600-20/2.50 IRC5 Document ID: 3HAC032885-001 Revision: AF © Copyright 2009-2023 ABB. All rights reserved. Specifications subject to change without notice.

Open the catalog to page 3

The information in this manual is subject to change without notice and should not be construed as a commitment by ABB. ABB assumes no responsibility for any errors that may appear in this manual. Except as may be expressly stated anywhere in this manual, nothing herein shall be construed as any kind of guarantee or warranty by ABB for losses, damage to persons or property, fitness for a specific purpose or the like. In no event shall ABB be liable for incidental or consequential damages arising from use of this manual and products described herein. This manual and parts thereof must not be...

Open the catalog to page 4

2 Specification of variants and options 71 © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 5

This page is intentionally left blank

Open the catalog to page 6

Overview of this specification Overview of this specification About this product specification This product specification describes the performance of the manipulator or a complete family of manipulators in terms of: • The structure and dimensional prints • The fulfilment of standards, safety, and operating equipment • The load diagrams, mounting or extra equipment, the motion, and the robot reach • The specification of available variants and options The specification covers the manipulator using the IRC5 controller. Usage Product specifications are used to find data and performance about...

Open the catalog to page 7

© Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 9

This page is intentionally left blank

Open the catalog to page 10

1 Description 1.1.1 Introduction to Structure 1 Description 1.1 Structure 1.1.1 Introduction to Structure Robot family The IRB 4600 series is ABB Robotics pioneer of the new sharp generation with enhanced and new capabilities. The design has been optimized to make it superior for the targeted applications. The IRB 4600 will focus on further expansion in material handling, machine tending, laser- and water jet cutting, dispensing, measuring, assembly and welding applications. Operating system The robot is equipped with the IRC5 controller and robot control software, RobotWare. RobotWare...

Open the catalog to page 11

1.1.1 Introduction to Structure Continued rust inhibitor to the fluid or take other measures to prevent potential rust formation on the mentioned. The entire robot is IP67 compliant according to IEC 60529 - from base to wrist, which means that the electrical compartments are sealed against water and solid contaminants. Among other things all sensitive parts are better protected than the standard offer. Selected Foundry Plus 2 features: • Improved sealing to prevent penetration into cavities to secure IP67 • Additional protection of cabling and electronics • Special covers that protect...

Open the catalog to page 12

1.1.1 Introduction to Structure Continued As the robot is designed for very harsh environments, an extended service and maintenance program is required. Special care must be taken when replacing parts or performing other maintenance and service that breaks the paint surface as the paint surface act as a protective barrier. For detailed information of the maintenance program, see chapter Maintenance in the product manual. It is highly recommended to sign a Service Agreement with ABB due to difficult and severe environmental conditions. The Foundry Prime robot can be cleaned with appropriate...

Open the catalog to page 13

1 Description 1.1.1 Introduction to Structure Continued Manipulator axes Product specification - IRB 4600 3HAC032885-001 Revision: AF © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 14

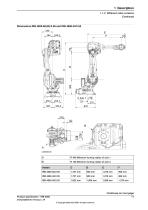

1.1.2 Different robot versions The IRB 4600 is available in four versions and all versions can be floor mounted, inverted or tilted (up to 15 degrees around the Y-axis or X-axis). © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 15

1 Description 1.1.2 Different robot versions Continued Continues on next page 16 Product specification - IRB 4600 3HAC032885-001 Revision: AF © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 16

Continues on next page © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 17

1.1.2 Different robot versions Continued Dimensions IRB 4600-20/2.50 A Product specification - IRB 4600 3HAC032885-001 Revision:AF © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 18

The listed standards are valid at the time of the release of this document. Phased out or replaced standards are removed from the list when needed. General The product is designed in accordance with IS0 10218-1:2011, Robots for industrial environments - Safety requirements -Part 1 Robots, and applicable parts in the normative references, as referred to from ISO 10218-1:2011. In case of deviations from ISO 10218-1:2011, these are listed in the declaration of incorporation which is part of the product delivery. Normative standards as referred to from ISO 10218-1 Continues on next page ©...

Open the catalog to page 19

1.2.1 Applicable standards Continued Standard i Only valid for arc welding robots. Replaces IEC 61000-6-4 for arc welding robots. ii Only robots with protection Clean Room. Product specification - IRB 4600 3HAC032885-001 Revision: AF © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 20

1 Description 1.3.1 Introduction to Installation 1.3 Installation 1.3.1 Introduction to Installation General The IRB 4600 is available in four versions and all versions can be floor mounted, inverted or tilted (up to 15 degrees around the Y-axis or X-axis), for more details see the product manual(also valid for inverted robot or inverted mounting). Depending on the robot version, an end effector with max. weight of 20 or 60 kg including payload, can be mounted on the tool flange (axis 6). See Load diagrams on page 40. Extra loads Extra loads, which are included in the load diagrams, can be...

Open the catalog to page 21

Protection standards Standard IP67 Foundry Prime IP67, and Foundry Plus IP67. Explosive environments The robot must not be located or operated in an explosive environment. Product specification - IRB 4600 3HAC032885-001 Revision:AF © Copyright 2009-2023 ABB. All rights reserved.

Open the catalog to page 22All ABB Robotics catalogs and technical brochures

-

AMR P304

2 Pages

-

IRB 6700

176 Pages

-

IRB 4600

2 Pages

-

IRB 910INV

90 Pages

-

IRB 14000

128 Pages

-

IRB 460

2 Pages

-

IRB 2400

60 Pages

-

IRB 1600/1660

88 Pages

-

IRB 1410 Industrial Robot

48 Pages

-

MU series

2 Pages

-

IRB 5500-22/23

4 Pages

-

IRB 52

2 Pages

-

IRB 910SC series

58 Pages

-

Robotics product range

4 Pages

-

IRB910SC

56 Pages

-

Robotics product range

35 Pages

-

Press Automation Solutions

28 Pages

-

IRBT 4004/6004/7004

2 Pages

-

IRB 1100

20 Pages

-

ABB create

24 Pages

-

LIVING LEVELS

44 Pages

-

IRB 6660 - Industrial Robot

4 Pages

-

IRB 120 industrial robot

2 Pages

-

Function Package IRB 4400

2 Pages

-

PalletPack 460

2 Pages

-

Atomizer Upgrades

2 Pages

-

RacerPack

13 Pages

-

RB 910SC SCARA Overview

38 Pages

-

IRB 6660FX

2 Pages

-

IRB 1660ID

17 Pages

-

A50-0406-1660

149 Pages

-

IRB 1660ID

2 Pages

-

IRBP L Workpiece positioner

2 Pages

-

FlexTrack IRT 501

2 Pages

-

IRBT X004 Track Motion

2 Pages

-

ROB0245EN RacerPack

2 Pages

-

IntegratedFC_ROB0243EN

2 Pages

-

IRL 600 Flexlifter 600

2 Pages

-

FlexLifter IRL100 IRL190

2 Pages

-

FlexGun

2 Pages

-

RobotStudio Cutting PowerPac

2 Pages

-

Laser Cutting Software

4 Pages

-

TSC

2 Pages

-

7th axis

2 Pages

-

2K Mixer

2 Pages

-

FlexPLP IRPLP

2 Pages

-

IRB 8700

2 Pages

-

YuMi®

4 Pages

-

IRBP i-L/ i-T/ i-A

2 Pages

-

IRBT 15_16_26

2 Pages

-

ABB Laser Cutsheet_IRBP K

2 Pages

-

ABB Laser Cutsheet_IRBP R

2 Pages

-

RobotWare Cutting

2 Pages

-

IRB 7600 - the Power Robot

20 Pages

-

IRB 140 Industrial Robot

2 Pages